|

|

Plastic solenoid valves have specific advantages and disadvantages, as well as specific application areas in chemical engineering, pharmaceutical technology, and process engineering. Here are some pros and cons of plastic solenoid valves:

Advantages of Plastic Solenoid Valves:

Corrosion Resistance: Plastic valves are resistant to a wide range of chemicals and do not corrode, making them suitable for use in demanding environments.

Lightweight: Plastic valves are lighter than metal valves, making them easier to handle and transport.

Good Insulating Properties:

- Plastics are generally good insulators, making them suitable for applications involving high temperatures or electrical currents.

- High Chemical Resistance: Plastics are typically resistant to a wide range of chemicals, making them ideal for use in the chemical and pharmaceutical industries.

- Cost Savings: Plastic valves are generally more cost-effective than metal valves.

Disadvantages of Plastic Solenoid Valves:

- Lower Mechanical Strength: Compared to metal valves, plastic valves have lower mechanical strength and can break or become damaged when overloaded.

- Temperature Limitations: Plastic valves have temperature limitations and may deform or melt at high temperatures.

- High Pressure Limitations: Plastic valves are less suitable for high-pressure applications compared to metal valves.

Application Areas of Plastic Solenoid Valves in Chemical Engineering, Pharmaceutical Technology, and Process Engineering:

- Chemical Dosing: Plastic solenoid valves are suitable for precise dosing of chemicals in chemical and pharmaceutical technology.

- Sampling: Plastic valves can be used for sampling liquids and gases in process engineering.

- Cleaning Processes: Plastic valves find application in cleaning processes in the food and beverage industry due to their resistance to cleaning agents.

- Water Treatment: Plastic solenoid valves are also used in water treatment for filtering, dosing, and regulating water.

Summary:

Plastic solenoid valves are widely used in chemical engineering, pharmaceutical technology, and process engineering due to their specific advantages and disadvantages. With their corrosion resistance, lightweight design, good insulating properties, and high chemical resistance, they are well-suited for demanding environments, high-temperature applications, and chemical dosing and sampling tasks. However, they have limitations in terms of temperature and pressure resistance as well as lower mechanical strength compared to metal valves. Nonetheless, plastic solenoid valves provide a cost-effective alternative.

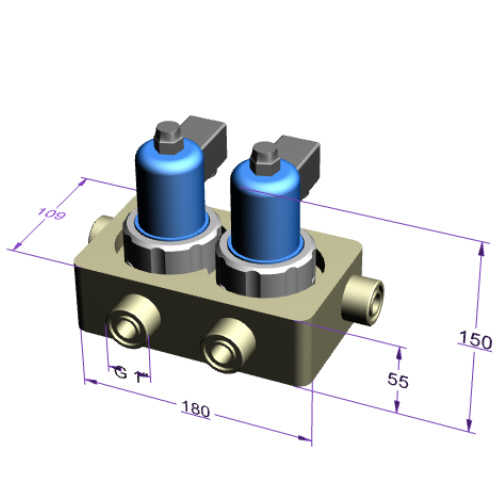

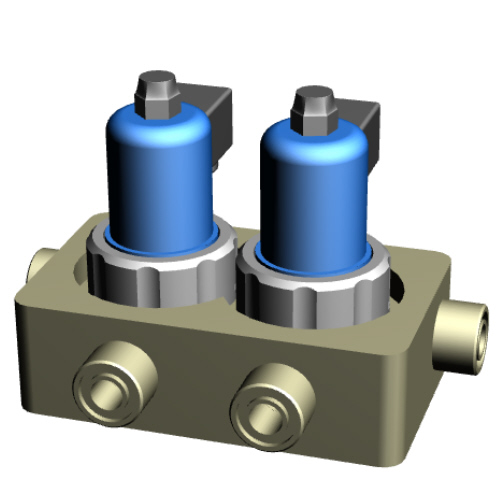

In our state-of-the-art production facility, we manufacture plastic solenoid valves in a block design according to the specific requirements of our customers. These solidly constructed valves offer robust performance and precise control. Whether itís tight installation conditions or an optimized pipeline network, our block design solenoid valves are the ideal choice. Our team of technicians is always available to assist you with engineering and application support. We are also happy to provide you with quotes for other variants upon request.

|