USE OF HAND-HELD PLASTIC VALVES IN EX ZONESALEXANDER KAIL |

|

Plastic valves can be found in all sorts of industries, and for some years also valves made of conductive plastics. The advantage of these valves is the combination of internal and external corrosion resistance and conductivity. Classic application: corrosive and highly flammable mixed media such as those found in the chemical or pharmaceutical industry in the area of EX zones, which are subject to the ATEX directives. There are basically two main directives that deal directly with ATEX: the ATEX 1999/92 / EC operating directive and, more recently, the ATEX Directive 2014/34 / EU (which replaces the previous Directive 94/9 / EC). Many plant operators are unsettled by the guidelines. Are you allowed to use plastic valves in general? Do the fittings have to be conductive? Is it true that hand-operated plastic valves are generally not subject to the ATEX guidelines? The following article tries to give a little clarity and to give the operator more security. |

THE USE OF CONDUCTIVE PLASTIC VALVESThe past 50 to 60 years have seen increased use of plastic valves. Materials such as PVC, PP, PE or PVDF are enjoying increasing popularity. Plastic fittings can be found today in all sorts of industries: chemical industry, pharmaceutical industry, agriculture, sanitary facilities, building technology, environmental technology, etc  |

The further development and improvement of the design features of the various valve types have also contributed to the extended use of plastic valves. But developments in this area are only at the beginning. Advances in materials offer new opportunities and can now cover other uses.  |

|

For a long time, the advantages of certain mixed materials such as glass fiber reinforced polypropylene, which has very good mechanical properties, have been known. Valves made of conductive plastics have also been on the market for some years (Fig. 1). You will also find matching fittings, pipes and even plate material. Normal polymers have about 15 times lower conductivity than metallic materials. The advantage of the conductive valve is the combinable coverage of two problems: internal and external corrosion resistance and conductivity. Classic application: corrosive and highly flammable mixed media such as those found in the chemical or pharmaceutical industry. The main application is in the area of the zones, which are subject to the ATEX guidelines (ATEX comes from Atmosphères Explosibles) of the European Union. There are two main principles of the principle directly related to ATEX: the ATEX Operating Directive 1999/92 / EC and, more recently, the Table 1: Properties of a mixed material made of carbon fibers and polypropylene |

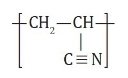

ATEX Product Directive 2014/34 / EU (which replaces the previous Directive 94/9 / EC). WHAT IS A CONDUCTIVE PLASTIC VALVE?Until now, there were only ball valves, butterfly valves and non-return valves in PP-el on the market. Polypropylene itself is not a good conductive plastic. He is one of the classically insulating materials. What the conductivity significantly increased is the addition of carbon fibers. The carbon fiber is a certain form of graphite. Carbon atoms, as six-membered rings, form long and fine surfaces. You could think of them as graphite ribbons. The binding of many ribbons then give the fibers. To make carbon fibers, you need organic polymer fibers. These polymers are mostly acrylonitrile polymers.  |

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||||||||||||||

|

If we continue to focus on plastic fittings, we should take a closer look at some details of the ATEX guidelines. ATEX DIRECTIVE 99/92 / ECAs is well known, the operator must classify his operations or operations in ATEX zones. There are also certain criteria for categorizing the device groups. The equipment groups have changed from Directive 94/9 / EC to Directive 2014/34 / EU (Table 2). The zones (0, 1, 2 for gases, vapors, mists and 20, 21, 22 for dust) must be protected against potential sources of explosion. Devices, protective devices and other components must be selected accordingly. Point 2.5 of Annex II to the Directive states: "All necessary measures shall be taken to design, construct, assemble, install and install the workplace, work equipment and associated connection devices provided to the worker, and so on be maintained and operated so that the risk of explosion is kept as low as possible ... "The operator is thus here for the first time taken into account by the legislature |

components such as the operator when using devices in potentially explosive atmospheres. There are several paragraphs in the directive that both operators and manufacturers should consider: Article 2 Definitions, § 5"Hazardous Area" (An area where the atmosphere may become explosive due to local and operational conditions). But this excludes some media. The VDMA, in its ATEX Guide, gives the example of an H2-Cl2 mixture that is highly flammable is, but not subject to atmospheric conditions. This example is not covered by Directive 2014/34 / EU. For under "potentially explosive atmospheres", the directive gives the following definition (§4): "A mixture of air and combustible gases, vapors, mists or dusts under atmospheric conditions, in which the combustion process, after ignition, transfers to the entire unburnt mixture". |

ATEX DIRECTIVE 2014/34 / EUThis directive replaces the ATEX Directive 94/9 / EC since February 2014. It should be both the manufacturers Article 2 Definitions, § 9"Intended Use" means the use of a product in a manner specified by the manufacturer by assigning the device to a particular device group and category or providing all information necessary for the safe operation of the protection system, the device or the device Component are necessary. Here the manufacturer is taken into account. An identification of a fitting could then look like this (Fig. 2). The classification is according to Table 2. Annex II, § 1.1 Selection of materials, 1.1.1."The materials used for the construction of the equipment and protective systems must not cause the triggering of an explosion, taking into account operationally foreseeable stress." This excerpt from the directive is very important and very explicit. The biggest problem with flammable media, especially in the media, which are conveyed in pipelines, is the friction electricity (triboelectric effect). In most cases, the resulting charges are not dangerous, but some products may cause electrostatic discharges to ignite the medium. The amount of charge depends on the properties of the medium, the flow rate, the working method, the size of the pipeline and the material used. Thermoplastics normally used have a surface resistance greater than or equal to 1013 ohms. Here can be a discharge of the electrostatic  |

In our example, the operator bears the full responsibility. So he can not rely on the manufac- turerís certificate, but has to make sure that the fittings used are conductive.

Current can not be guaranteed because these values characterize an insulating material. A conductive plastic like the PP-el has a surface resistance of <106 ohms. Measurements of the surface resistance of conductive plastic ball valves made of PP-el in a mixing ratio of approximately 80% polypropylene and 20% graphite give values of 103 to 104 ohms. These are very good values and thus the conductivity is guaranteed. The bond between PP and graphite is so good that the chemical resistance continues to be guaranteed. Annex II, § 1.3 potential sources of ignition, 1.3.2."Static Electricity Hazards" "Electrostatic charges that could lead to hazardous discharging operations must be avoided by appropriate means." Here again an indication of the danger that can arise from electrostatic charges. A hazard analysis of the plant, as it has to be carried out by the operator by the guideline, can guarantee from the beginning the basic conditions for an unrestricted commissioning of the plant according to ATEX guidelines. When using plastic piping, it must then be immediately clarified whether there is a risk of static electricity. If this is the case, it is essential to use a conductive plastic, not just the fittings, but the entire pipe system as well. It should be noted that the manufacturer should also make its contribution by providing the operator with all relevant information regarding device groups and categories for use in potentially explosive atmospheres.  Bild 2: Marking of plastic valves according to ATEX |

Annex II, § 1.3 potential ignition sources, 1.3.3."Dangers due to electrical leakage and leakage currents" "Electrical stray and leakage currents in conductive parts of the device, which may cause sparks, surface overheating or dangerous corrosion, must be prevented." The legislator again gives a clear warning to manufacturers and operators and points out the dangers of electrical leakage and leakage currents. CONCLUSIONNotwithstanding the fact that manual valves are generally not subject to ATEX Directive 99/92 / EC, the manufacturer of valves has the duty, when used in an explosive environment, of all possible hazards that may arise from the proper operation of his product analyze. Automated valves are excluded here because the drive is subject to a corresponding conformity assessment procedure. In any case, it is certain that the plant operator is responsible for selecting his valves. Today there are conductive plastic pipe systems that can solve potential problems in EX areas. The development continues in the field, the production of conductive plastics becomes more economical over time, and the range of other types of fittings in conductive plastics increases (Fig. 3). AUTHOR .................................................. ................................ ALEXANDER WEDGE SAFI GERMANY Plastic fittings-Vertriebs-GmbH 64319 Pfungstadt Tel .: 06157-81919 alexander.keil@safi-valves.com www.safi-valves.com Published in the magazine Industriearmaturen 02/2015 - www.Industriearmaturen |

Figure 3: Fitting made of conductive plastic for a gas scrubber system |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|