STRAINERS FOR CHEMICAL INDUSTRY

|

|

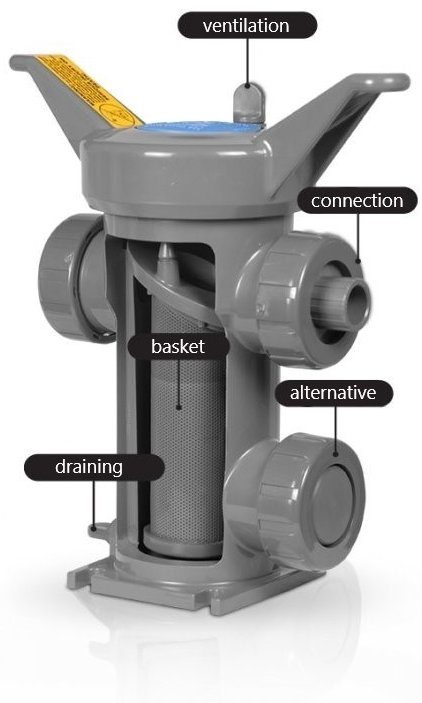

CONVINCING TECHNOLOGYAT A GLANCE• available in sizes d 20 to d 200 mm • low pressure loss • long service life • baskets made of PVC U, PVC C, PP and stainless steel • perforation of the baskets from 40 micron to 4,8 mm • easy cleaning of the baskets • single and double units available • alternative operation modes according to application • made of PVC U, PVC C ,PP and transparent copolyester • silicone-free O-ring seals  |

STRAINERFOR PROTECTION OF PLANT COMPONENTSFlowing liquids in pipe systems might be polluted by substances, which could lead to blocking the system and failure of plant components. For this reason, strainers are inserted either at the entry point of the fluid into specific parts of a pipe system, or directly upstream vulnerable plant parts (e.g. valves or pumps). LOW PRESSURE LOSS

|

|

|

CONNECTION VARIANTSFOR MULTIPLE APPLICATIONSPP/ST flanges, PE inserts, PP inserts, threaded sockets |

|

STRAINERFOR PROTECTION OF PLANT COMPONENTSShould it be necessary to protect a plant or plant components against polluting substances by means of a strainer, it is most important to find a suitable basket. The basic rule is to choose a screen insert according to the particle size to be removed from the process fluid. A finer perforation or mesh size as necessary will lead to accelerated blocking of the strainer. If you have the choice between two differently perforated baskets, select the coarser one. Guideline: Choose the mesh size resp. the perforation of the basket half the size of the particles you need to hold back.  |

|

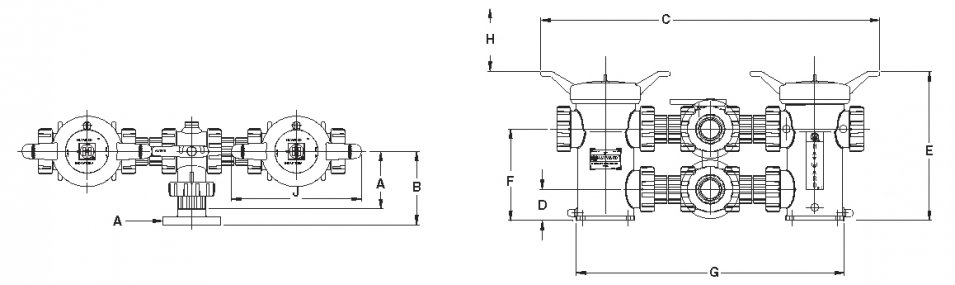

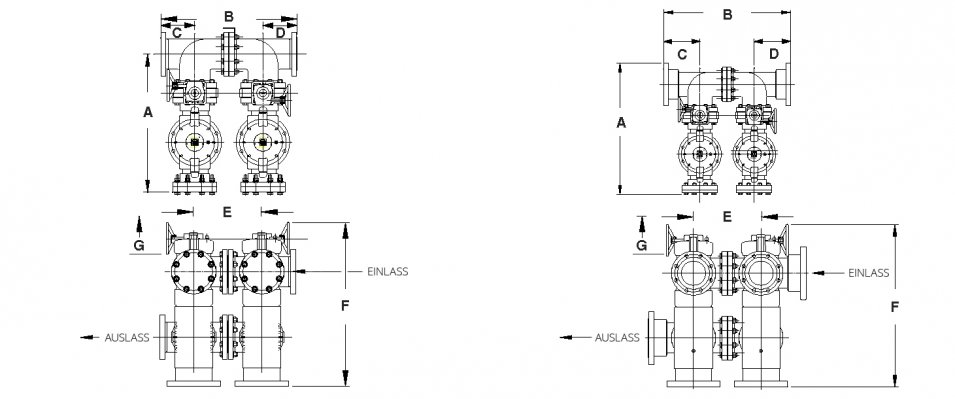

SINGLE OR DOUBLE VERSIONWhen using strainers in pipe systems, there are two operating modes - normal operation and uninterrupted operation. Normal operation means that the plant can be stopped for maintenance purposes or that it is possible to maintain the plant during daily or weekly downtimes. In this case a single-type strainer will be sufficient. If an uninterrupted operation is required, which means that cleaning of the basket must be possible without interruption of the operation, use of a double-type strainer is indispensable. This type of strainer allows alternate use of the two strainers by switching over the combination valve. Consequently the maintenance intervals for Kwerk strainers are significantly longer. |

|

|

SELECTION CRITERIAThe free flow area on the screen basket is an important aspect in the selection of strainers. Installing the strainers in pipelines with nominal sizes corresponding to the connection diameter of the housing, ensures usually that the basket has enough free flow area. Under no circumstances the pipeline should be reduced ahead of the strainer. Too small strainers will lead to high pressure loss. Furthermore, viscosity of the process medium may also cause loss of pressure. In case the viscosity of the medium used is higher than the viscosity of water, you should consult one of our application technicians. It might be recommended to choose a larger strainer or to operate multiple strainers in parallel, in order to reduce pressure loss. A pressure loss on the clean strainer of more than 150 mbar shows that it is too small for that application. After maintenance, when the basket is clean, the complete flow area is available. As soon as the basket begins to be blocked by pollutions, the relation between the pipe cross section and the flow area of the basket is getting continually smaller. Even though the strainer has been generously dimensioned, the free flow area can rather quickly get smaller than the pipe cross section. This will increase the pressure loss, reduce the flow rate through the strainer and require frequent cleaning. Another aspect is the capability of holding back the pollutions. If for a specific application an increased pollution load has to be expected on regular basis, the basket will be filled within short time and cleaning of the basket becomes necessary. In order to extend the maintenance intervals, it is recommended to use in this case a larger strainer. |

ESTIMATE OF PRESSURE LOSSAfter having selected a strainer with suitable screen basket according to the above mentioned considerations, it is necessary to check the pressure loss arising under operating conditions. The pressure loss has to be calculated with the following formula; Q delta P = pressure loss in bar delta P =[ ------------ ] ² Kv = flow rate coefficient / Cv-value Kv Q = flow rate in m³/h The Cv-value for the particular strainer with corresponding basket, is listed in the table below. |

CV VALUES - CALCULATORY ESTIMATE OF THE PRESSURE LOSS |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

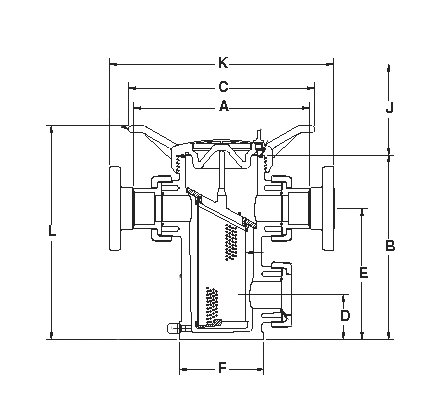

TECHNICAL DATA AND DIMENSIONS- SIMPLEX STRAINER - |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TECHNICAL DATA AND DIMENSIONS- DUBLEX STRAINER - |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||

DELIVERY RANGE SIMPLEX STRAINERSPlease note: - besides the standard program, we supply also customized connection variants. - sealing material EPDM, also available in FPM on request.. The PP version can be delivered only in FPM, |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|