CPVC Pipe Systems - General characteristics |

Material propertiesThe material data given are standard values that may differ depending on the processing method. Therefore, they can not be easily transferred to finished parts. |

|

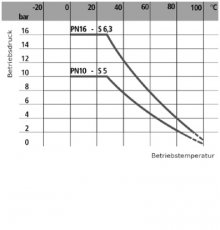

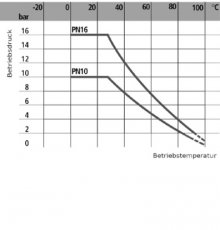

Pressure-Temperature-graphThe graph is based on a surrounding temperature of 20°C and water as a medium. The pressures in the chart are valid for a life span of 25 years and an included safety margin of 2.5. |

|

|

|

|

Advantages of the CPVC systemDue to the resulting interactions between the chlorine atoms in the polymer chains, the CPVC material has, in addition to a high degree of hardness and dimensional stability, excellent chemical resistance at higher temperatures (advantage over PVC-U). These properties predestine the material CPVC for the production of pressurized piping systems |

Chemical resistanceCPVC has excellent chemical resistance, even at high temperatures and media concentrations. Compared to a large number of dilute or concentrated acids and alkalis, alkalis and aliphatics, CPVC has to be classified as resistant. Opposite media like esters, ketones, chlorinated hydrocarbons and some others. Solvents is CPVC swelling or solvable. CPVC is not resistant to strong oxidants. The chemical resistance, however, depends on many factors, such as operating temperature, operating pressure, concentration and other factors. In this case, you can look up the resistance in our resistance list or contact our product management. |

Chemical resistanceCPVC has excellent chemical resistance, even at high temperatures and media concentrations. Compared to a large number of dilute or concentrated acids and alkalis, alkalis and aliphatics, CPVC has to be classified as resistant. Opposite media like esters, ketones, chlorinated hydrocarbons and some others. Solvents is CPVC swelling or solvable. CPVC is not resistant to strong oxidants. The chemical resistance, however, depends on many factors, such as operating temperature, operating pressure, concentration and other factors. In this case, you can look up the resistance in our resistance list or contact our product management. |

Temperature and pressure application areasCPVC can be used in the operating temperature range from 0 ° C to +90 ° C (short-term), whereby kwerk.de does not recommend the continuous use of CPVC in areas above +80 ° C. Due to the high chlorine content, the advantages of CPVC are particularly evident in the range of elevated operating temperatures. With regard to the internal pressure load capacity of pipes and fittings, we refer to the above "pressure-temperature diagram". For the maximum internal pressure load capacity of fittings, please also note the instructions in the corresponding Fittings or consult with our product management. |

Electrical PropertiesCPVC is a polar, amorphous thermoplastic with excellent insulation properties. Due to the resulting possible static charge, CPVC must not be used in applications where there is a risk of ignition or explosion Like all thermoplastics, CPVC has a relatively high thermal expansion coefficient (0.07 mm / m ° C). This fact must be taken into account in advance when planning the pipeline system. There are various possibilities for this: installation of expansion bends or compensators, as well as the "fixed" clamping via fixed points. Since this requires sound knowledge in dealing with plastics, we recommend carrying out a corresponding system design with PC computer programs |

Low weightCPVC systems weigh only half compared to copper pipe installations and only 1/5 compared to steel pipe systems. This ensures easier handling and opens up areas of application in which, in conjunction with the special properties of CPVC, metallic systems can be replaced Easy connectionCPVC piping components are bonded together by gluing. The production of adhesive joints requires sufficient expertise, i.a. in training courses that can be acquired. Concerning. For gluing, please observe the special specifications of the adhesive suppliers or the adhesive instructions published by KRV (Kunststoffrohrverband e.V.) as well as the corresponding DMS leaflets. |

standardizeThe pipes, fittings and fittings supplied by kwerk are made according to the most important national and international standards Standards and guidelines produced, such as: - DIN 8079 - DIN 8080 - DIN 2999 - ISO 228 - ISO 727 - EN ISO 15493 |

approvals- Supplier confirmation for use in drinking water applications - Supplier confirmation for the use of food applications - WRAS-UK = pipes and fittings for cold water applications - NSF-USA = Pipes and fittings for cold water applications - Lloyd’s Register - TA-Luft approval for 2 and 3-way ball valves - TA-Luft approval for FK butterfly valves - TA-Luft approval for diaphragm valves - DIBt approvals for 2-way ball valves type VKD |

tube supportFrequently, pipes with "unhindered change in length" are guided in suspended pipe clamps. The pipe has the possibility to slide in the pipe clamp. Therefore, these constructions must be as stable as possible, yet they must not interfere with the axial movement of the tube. The metallic clamp types must not have any sharp edges or burrs that could damage the pipe. In the immediate vicinity of the clamp, there must be no obstacles (such as moldings, sleeves, welds) that affect the mobility of the pipeline. When designing piping systems with "prevented" length change, guide clamps must be installed. You must ensure that the tube does not buckle laterally due to the occurring compression. The possibility to slide the pipe is not required here in contrast to the sliding clamp. |

Support for heavy pipeline partsFittings, filters, or other heavy piping parts should always be secured independently of the piping to keep inadmissible loads from the piping system, e.g. can be used for intermediate flanges of butterfly valves instead of loose flanges valve mounting plates or ball valves special ball valve holders. |

Pipe clamp distancesPipe clamp distances for tubes made of CPVC (PN 10) in a medium with a density <1 g/cm³ |

|

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|