Bonding of plastic pipe systemsThe "chemical welding" by means of solvents or simply "BONDING", is a specially developed connection for pipes and fittings from PVC-U. Bonding is realized by means of adhesives, resulting from the solution of PVC-U polymer in an appropriate solvent. The adhesives soften the walls of the pipes and fittings, followed by "welding" with material contained in the walls. The "chemical welding" allows long-term bonds, which guarantee the same properties of chemical and mechanical resistance than the original pipes and fittings. The adhesives have to be selected depending on the type of resin, as the solvents and filler materials contained therin may vary. Please note that in a pipe system only adhesives from the same series are allowed to be used for the PVC-U pipes as well as for fittings and valves. |

|

Notice: The adhesive used for bonding parts from the PVC-U system may in no case be used for bonding foreign parts. Instructions for bondingFirst of all, it is very important to check if the accessory parts are in good condition, especially have to be verified the flowability, the homogeneity of the adhesive and the expiration date. Cut the pipe vertically. To obtain a good cut, it is recommended to use a suitable pipe cutter with rollers. Such an instrument is produced especially for cutting plastic pipes. |

|

|

Chamfer the outer surface of the pipe end, so that it can be inserted correctly into the fitting (angle 15°). This procedure is extremely important, as otherwise the adhesive may be scraped off, which can affect the quality of the connection and has to be done by means of particular chamfering devices. |

|

|

Measure the depth of the gluing sleeve. Highlight the measured value on the pipe end. |

|

|

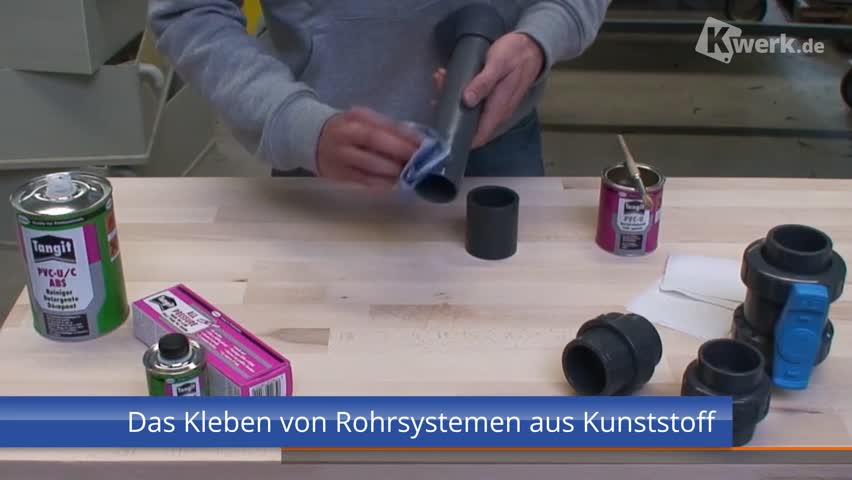

Remove all traces of dirt or grease from the entire bonding length with a clean absorbant paper towel or with a brush moistened with cleaning agent. Repeat the same process on the inside area of the sleeve, in order to soften its surface.

Let the surfaces dry for some minutes, before applying the adhesive. The cleaning agent not only cleans the surfaces before bonding, but also has a softening effect and prepares the parts for the adhesive, in order to achieve an optimum bond. |

|

|

Spread the adhesive evenly and in longitudinal direction on the parts to be bond (outer surface of the pipe and inner surface of the gluing sleeve). Use a rough brush of appropriate size. In any case it is recommended to use a brush at least half as big as the diameter of the pipe. Apply the adhesive on the entire length of the connecting surfaces of pipe and fitting: - on the complete insertion depth up to the end stop - on the total bonding area of the pipe (which has been previously marked outside). |

|

|

|

Insert the pipe with the entire bonding length into the fitting, without twisting. Only after this process, both components can be rotated slightly (maximum rotation between pipe and fitting: 1/4 turn). By means of this rotation, the applied adhesive will be equalised. |

| The bond between pipe and fitting must be completed very quickly (times longer than 20-25 seconds are to be avoided). Depending on the outer diameter of the pipe and the forces occuring, bonding of pipe and fitting has to be carried out as follows: - outer diameter d < 90 mm by one person. - outer diameter d 90 mm up to < 160 mm by two persons. - outer diameter d > 160 mm with help of insert devices. |

|

Fix the parts for some seconds, immediately after having inserted the pipe into the fitting (until the end stop). Then remove the excess adhesive by means of crepe paper or cloth, if possible also from the inner surfaces.

Drying of the adhesive: It is very important to let the bonded parts rest for a while, in order to ensure a natural flash-off of the adhesive. Flash-off time depends on the stress, which the bond has to withstand later. |

|

The following minimum times at room temperature have to be observed, • before the bond can be strained: - 5 to 10 minutes for ambient temperatures > 10°C - 15 to 20 minutes for ambient temperatures < 10°C • pressure at repair weld not being subject to hydraulic tests, effective for all dimensions and pressures: - 1 hour per bar • in the case of bonds being subject to hydraulic tests for pipes and fittings up to PN 16 and independent from the diameter, it is essential to wait: - at least 24 hours. Flash-off times of the adhesive depend on the room temperaure as well. In the event of special climate conditions (humidity, temperature, etc.) we recommend you to get in touch with our technical service and/or the manufacturer of the adhesive, in order to obtain further support. |

| Important notes: Should the outer diameter of the pipe and the inner diameter of the fitting be near the limit of the tolerance range, the dry pipe may in no case be inserted into the dry gluing sleeve. This will only be possible after having applied cleaning agent and adhesive on the the two parts to be bond. • The adhesive has been produced from the same resin as the PVC-U, which the company FIP uses for manufacturing pipes, fittings and valves from the PVS-U system. Unless otherwise indicated, the adhesive has to cover the following tolerances: - max. excess: 0,2 mm. - max. gap: 0,6 mm. • When using the adhesive and the cleaning agents, it is advisable to respect the following instructions: • Wear safety gloves and safety glasses, in order to protect eyes and hands. • The adhesive and the cleaning agent may be used only in rooms with sufficient ventilation (they irritate airways and eyes). • Adhesive and cleaning agent contain solvents and because of their volatility, it is important to close the bins immediately after use. • Solvents in gaseous phase tend to form flammable gases. For this reason, all kinds of ignition sources have to be removed or avoided, such as welding operations, electrostatic charge and smoking. The instructions given by the manufacturer on the packaging have to be observed. • It is advisable to perform the bonding only at a temperature between + 5 and + 40° C, in order to ensure optimum adhesion. • Quantity of adhesive for one bonding depends on various factors (climate, dimensions of the pipe, viscosity of the adhesive, experience of the personnel, etc.), factors, which are not easy to evaluate. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|