| housing |

Connection size |

material |

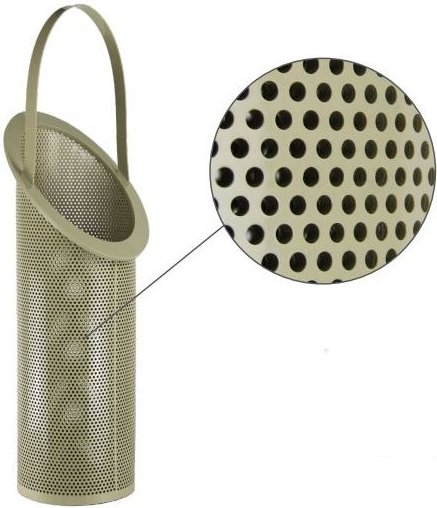

perforation |

basket volume |

item number |

| DN 200 |

Ø75 DN65 |

PP / FRP |

Rv 2,0 - 3,5 |

5,2 L |

PS-PPFRP-200/65-1 |

| DN 200 |

Ø75 DN65 |

PP / FRP |

Rv 3,0 - 5,0 |

5,2 L |

PS-PPFRP-200/65-2 |

| DN 200 |

Ø75 DN65 |

PP / FRP |

Rv 4,0 - 6,0 |

5,2 L |

PS-PPFRP-200/65-3 |

| DN 200 |

Ø75 DN65 |

PP / FRP |

Rv 5,0 - 7,0 |

5,2 L |

PS-PPFRP-200/65-4 |

| DN 200 |

Ø90 DN80 |

PP / FRP |

Rv 2,0 - 3,5 |

5,2 L |

PS-PPFRP-200/80-1 |

| DN 200 |

Ø90 DN80 |

PP / FRP |

Rv 3,0 - 5,0 |

5,2 L |

PS-PPFRP-200/80-2 |

| DN 200 |

Ø90 DN80 |

PP / FRP |

Rv 4,0 - 6,0 |

5,2 L |

PS-PPFRP-200/80-3 |

| DN 200 |

Ø90 DN80 |

PP / FRP |

Rv 5,0 - 7,0 |

5,2 L |

PS-PPFRP-200/80-4 |

| DN 200 |

Ø110 DN100 |

PP / FRP |

Rv 2,0 - 3,5 |

5,2 L |

PS-PPFRP-200/100-1 |

| DN 200 |

Ø110 DN100 |

PP / FRP |

Rv 3,0 - 5,0 |

5,2 L |

PS-PPFRP-200/100-2 |

| DN 200 |

Ø110 DN100 |

PP / FRP |

Rv 4,0 - 6,0 |

5,2 L |

PS-PPFRP-200/100-3 |

| DN 200 |

Ø110 DN100 |

PP / FRP |

Rv 5,0 - 7,0 |

5,2 L |

PS-PPFRP-200/100-4 |

| DN 300 |

Ø140 DN125 |

PP / FRP |

Rv 2,0 - 3,5 |

20,7 L |

PS-PPFRP-300/125-1 |

| DN 300 |

Ø140 DN125 |

PP / FRP |

Rv 3,0 - 5,0 |

20,7 L |

PS-PPFRP-300/125-2 |

| DN 300 |

Ø140DN125 |

PP / FRP |

Rv 4,0 - 6,0 |

20,7 L |

PS-PPFRP-300/125-3 |

| DN 300 |

Ø140 DN125 |

PP / FRP |

Rv 5,0 - 7,0 |

20,7 L |

PS-PPFRP-300/125-4 |

| DN 300 |

Ø160 DN150 |

PP / FRP |

Rv 2,0 - 3,5 |

20,7 L |

PS-PPFRP-300/150-1 |

| DN 300 |

Ø160 DN150 |

PP / FRP |

Rv 3,0 - 5,0 |

20,7 L |

PS-PPFRP-300/150-2 |

| DN 300 |

Ø160 DN150 |

PP / FRP |

Rv 4,0 - 6,0 |

20,7 L |

PS-PPFRP-300/150-3 |

| DN 300 |

Ø160 DN150 |

PP / FRP |

Rv 5,0 - 7,0 |

20,7 L |

PS-PPFRP-300/150-4 |

| DN 300 |

Ø225 DN200 |

PP / FRP |

Rv 2,0 - 3,5 |

20,7 L |

PS-PPFRP-300/200-1 |

| DN 300 |

Ø225 DN200 |

PP / FRP |

Rv 3,0 - 5,0 |

20,7 L |

PS-PPFRP-300/200-2 |

| DN 300 |

Ø225 DN200 |

PP / FRP |

Rv 4,0 - 6,0 |

20,7 L |

PS-PPFRP-300/200-3 |

| DN 300 |

Ø225 DN200 |

PP / FRP |

Rv 5,0 - 7,0 |

20,7 L |

PS-PPFRP-300/200-4 |

| DN 500 |

Ø280 DN250 |

PP / FRP |

Rv 2,0 - 3,5 |

69,7 L |

PS-PPFRP-500/250-1 |

| DN 500 |

Ø280 DN250 |

PP / FRP |

Rv 3,0 - 5,0 |

69,7 L |

PS-PPFRP-500/250-2 |

| DN 500 |

Ø280 DN250 |

PP / FRP |

Rv 4,0 - 6,0 |

69,7 L |

PS-PPFRP-500/250-3 |

| DN 500 |

Ø280 DN250 |

PP / FRP |

Rv 5,0 - 7,0 |

69,7 L |

PS-PPFRP-500/250-4 |

| DN 500 |

Ø315 DN300 |

PP / FRP |

Rv 2,0 - 3,5 |

69,7 L |

PS-PPFRP-500/300-1 |

| DN 500 |

Ø315 DN300 |

PP / FRP |

Rv 3,0 - 5,0 |

69,7 L |

PS-PPFRP-500/300-2 |

| DN 500 |

Ø315 DN300 |

PP / FRP |

Rv 4,0 - 6,0 |

69,7 L |

PS-PPFRP-500/300-3 |

| DN 500 |

Ø315 DN300 |

PP / FRP |

Rv 5,0 - 7,0 |

69,7 L |

PS-PPFRP-500/300-4 |

|

Other versions are available on request - send us your request

Technical changes reserved

|

|