Material PVC U gray

|

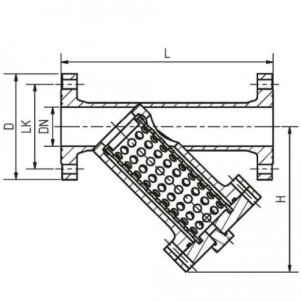

Dimensions |

fixed flange on both sides

DIN EN 1092-1, DIN 2501 - PN 10

O-rings EPDM |

fixed flange on both sides

DIN EN 1092-1, DIN 2501 - PN 10

O-rings FPM |

d

mm |

DN |

Inch |

PN

bar |

Item number |

Weight

kg |

Euro / pcs |

Item number |

Weight

kg |

Euo / pcs |

| 75 |

65 |

21/2" |

2 |

479995 |

7,80 |

Article in the webshop |

480000 |

7,80 |

Article in the webshop |

| 90 |

80 |

3" |

2 |

479996 |

10,00 |

Article in the webshop |

480001 |

10,00 |

Article in the webshop |

| 110 |

100 |

4" |

2 |

479997 |

12,50 |

Article in the webshop |

480002 |

12,50 |

Article in the webshop |

| 140 |

125 |

5" |

2 |

479998 |

20,00 |

Article in the webshop |

480003 |

20,00 |

Article in the webshop |

| 160 |

150 |

6" |

2 |

479999 |

26,50 |

Article in the webshop |

480004 |

26,50 |

Article in the webshop |

Material PP

|

| 75 |

65 |

21/2" |

6 |

480005 |

5,00 |

Article in the webshop |

480012 |

5,00 |

Article in the webshop |

| 90 |

80 |

3" |

6 |

480006 |

6,50 |

Article in the webshop |

480013 |

6,50 |

Article in the webshop |

| 110 |

100 |

4" |

6 |

480007 |

8,00 |

Article in the webshop |

480014 |

8,00 |

Article in the webshopp |

| 140 |

125 |

5" |

6 |

480008 |

13,00 |

Article in the webshop |

480015 |

13,00 |

Article in the webshop |

| 160 |

150 |

6" |

4 |

480009 |

17,00 |

Article in the webshop |

480016 |

17,00 |

Article in the webshop |

| 225 |

200 |

8" |

4 |

480010 |

24,00 |

Article in the webshop |

480017 |

24,00 |

Article in the webshop |

| 280 |

250 |

10" |

4 |

480011 |

30,00 |

Article in the webshop |

480018 |

30,00 |

Article in the webshop |

| Material PP to DN 500 available on request |

| Material PVDF |

| 75 |

65 |

21/2" |

10 |

480019 |

10,00 |

Article in the webshop |

480023 |

10,00 |

Article in the webshop |

| 90 |

80 |

3" |

10 |

480020 |

13,00 |

Article in the webshop |

480024 |

13,00 |

Article in the webshop |

| 110 |

100 |

4" |

10 |

480021 |

16,00 |

Article in the webshop |

480025 |

16,00 |

Article in the webshop |

| 140 |

125 |

5" |

10 |

480022 |

25,00 |

Article in the webshop |

480026 |

25,00 |

Article in the webshop |

Material PVDF to DN 200 available on request

|

|

|

|