UP-GF (FRP) PIPES, MOLDED PARTS AND CONNECTIONSPipes made of glass-fibre reinforced polyester resins (UP-GF) with and without

|

|

Glass-fibre reinforced plastic, abbreviated as GFRP (in German GFK = Glasfaserverstärkter Kunststoff), also referred to as duroplast, consists of plastic resin and a fibrous reinforcing material. Glass fibres impregnated with an unsaturated polyester resin (UP) or with a vinyl ester resin from the duroplast group, serve as reinforcement material. Glass-fibre reinforced plastic shows an excellent corrosion stability and high chemical resistance, even in aggressive environments, which makes it an appropriate material for pipe systems and tanks in the chemical industry and process engineering. Our new product line:  Part of our delivery program are: UP- GF pipes and molded parts - UP-GFRP pipes, 6.000 mm, 12.000 mm and special lengths - UP-GFRP molded parts, UP-GFRP fittings and UP-GFRP custom-made products - GFRP adhesive collars - GFRP loose type flanges - GFRP block flanges Lining materials - as per DIN 16965 - section 2 / pipe type B - - PP polypropylene as par DIN 8078 - GFRP PP molded parts, GFRP PP fittings and GFRP PP custom-made products - PVC U plasticizer-free polyvinylcloride as per DIN 8061, colour grey - PVC U plasticizer-free polyvinylcloride as per DIN 8061, colour red - PVC C post-chlorinated polyvinylcloride as per DIN 8080 - PE-HD high-density polyethylene as per DIN 8075 - PVDF polyvinylidenfluoride In the fields of plastic apparatus and plastic tank construction we provide custom-made products, among others also GFRP manhole covers. Our team, having nearly 40 years of work experience in production and application of UP-GF molded parts and connections, will be pleased to answer any additional question. Just call us: 0049 2602 999730. On request we will gladly send you a detailed quotation. All items you will also find in our webshop. |

|

PIPES MADE OF GLASS-FIBRE REINFORCED POLYESTER RESINS (UP-GF)WOUND - DIN 16965 - section 4 and section 2STANDARD LENGTHS: 6.000 MM, 12.000 MM, BLANKS ON CUSTOMER REQUESTPIPE TYPE D - DIN 16965 - Section 4GFRP pipes |

|

|

|

|

|

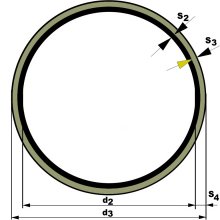

d2 internal pipe diameter d3 outside pipe diameter S2 chemical protection layer, at least 2,5 mm S3 wall thickness of the bearing laminate S4 S2 + S3 Pipe description using the example of DN 100 nominal diameter: Pipe DIN 16965 - D - 100 - 10 Used material and structure of the laminate For the pipes according to DIN, we utilize unsaturated polyester resin and textile glass according to DIN 16 964. The chemical protection layer (s2), a resin-rich inner layer, has a thickness of at least 2,5 mm. |

PIPE TYPE B - DIN 16965 - section 2Lining with thermoplastic materials or elastomers |

|

|

|

|

|

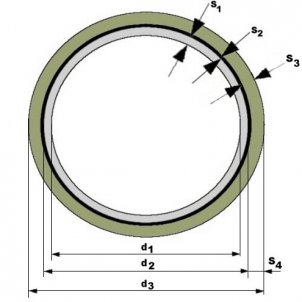

d1 internal pipe diameter d2 internal diameter of the laminate resp. outside diameter of the lining d3 outside pipe diameter S1 thickness of the thermoplastic or elastomeric lining S2 thickness of the bonding layer, max. 1mm S3 wall thickness of the bearing laminate S4 S2+S3 Used material and structure of the laminate: For applications in the chemical industry and process engineering the pipe type B is produced from thermoplastic material and elastomers with a laminate layer. Kwerk provides lined pipes and fittings of the B series, UP-GF in combination with PVCU, PVCC, PP, PE and PVDF. Description of a UP-GF pipe, type B, nominal diameter DN 100, nominal pressure PN 6 and PVC-U lining. Pipe description: Pipe DIN 16965 - B - 100 - 6 PVCU |

SUPPLY RANGE

|

|

Pipe DIN 16965, nominal pressure PN 16WOUND - PIPE TYPE D - DIN 16965 - section 4 LAMINATED ENDSSTANDARD LENGTHS: 6.000 MM, 12.000 MM, BLANKS ON CUSTOMER REQUEST |

|

|

Our molded parts you will find here: Delivery program UP-GF (GFRP) molded parts and custom-made products. |

Pipe DIN 16965, nominal pressure PN 6WOUND - PIPE TYPE B - DIN 16965 - section 2

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pipe DIN 16965, nominal pressure PN 10WOUND - PIPE TYPE B - DIN 16965 - section 2

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pipe DIN 16965, nominal pressure PN 16WOUND - PIPE TYPE B - DIN 16965 - section 2

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

GFRP - Glass- fibre reinforced plastic |

| Glass-fibre reinforced plastic, abbreviated as GFRP (in German GFK = Glasfaserverstärkter Kunststoff), also referred to as duroplast, consists of plastic resin and a fibrous reinforcing material. Glass fibres impregnated with an unsaturated polyester resin (UP) or with a vinyl ester resin from the duroplast group, serve as reinforcement material.

In Germany, the vinyl ester resin is identified officially as phenactylate resin and is based for the sorts e.g. Derakane 411-350 or Distrotone VE 100 on bisphenol A and for the sorts e.g. Derakane 470-300 or DION 9400 on novolac resin. Before processing, these resins are viscous solutions of so-called unsaturated polyesters, which are dissolved in copolymeriazable monomers (styrene). The final product GFRP consists of this plastic material and glass fibres. Good impregnation of the glass fibres with resin is of decisive importance for the product. Before impragnating the glasses accordingly by hand or automatically, radicals (peroxides) have to be added to the liquid resins, in order to imitate the reaction and to transfer the resin from the liquid state to a cross-linked state. During linking, no other fission products are produced. The solvent styrene will partly be released during processing. The process time takes 15 to 45 minutes and can be accelerated or slowed down by means of accelerators and/or inhibitors. With the three components (hardener, accelerator and inhibitor), the recipes are mixed individually according to the weather conditions and the necessary processing time and adapted to the specific processing performed. According to recipe starts within approximately 30 to 120 minutes an exothermic hardening reaction and warmth is released. This reaction brings about hardening of the unsaturated polyester resins under formation of cross-linked substances by means of copolymerization cured through radicals. With the styrene, the polyester molecules are forming network structures. A product manufactured like this can not be liquified by heating and not be dissolved by solvents (duroplast). |

The processed glasses and their percentage depend on the required mechanical properties. After the hardening process, the product can be utilized according to the requirements. For a certain time, a postpolymerization takes place, however this process is not measurable or detectable at all.

For disposa, the finished product can be burned (glass, ash) or stored, as a chemical reaction with any other materials is impossible. Typical applications for glass fibre reinforced plastic are: • Vehicle construction • Aviation • Ship building • Bridge construction • GFRP sections for "steel construction“ • GFRP rebars for concrete construction • Hall doors • Wind-driven power stations • Model making • Pipeline construction • Tank construction for the chemical industry • Apparatus engineering • Special components for chemically stressed parts • Insulation of electroconductive parts • Water slide complexes • Bathtubs, shower trays, washbasins • Jointless shower cabinets for use in mobile space units and sanitary containers • Tuning bumpers • Motorcycle fairings (tuning for weight reduction) • Interior covers (e.g. door panels in vehicles) • Head protection (e.g. firefighter helmets and motorsport helmets) • Facade construction • Tank construction (e.g. heating oil tanks and heat accumulators) • Silo construction (storage of animal feed and grain) |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|