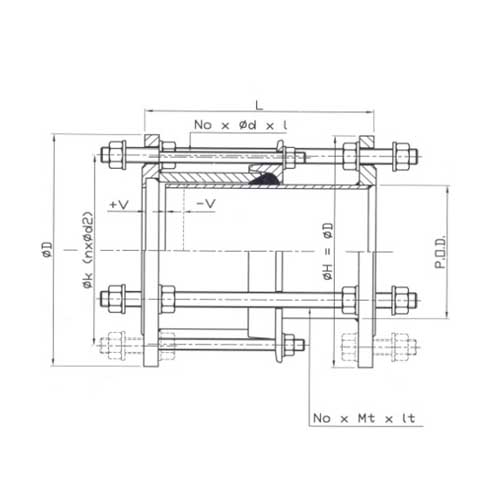

Flanged, Restrained Dismanteling Joints, Type HD-1, PN 10

delivery time: 10 days

|

||||||||||||||||||||

|

Material specification • High quality rolled steel to BS4360:1986 Grade 43A. • Fusion bounded epoxy coating, thickness approx. 200 microns. Other coatings such as hot dipped galvanised, transit coating or other epoxy coatings are available on request. • EPDM or NBR rubber gaskets. • Tie bars and nuts are made of steel BS970:Part1:1983 Grade 070 and are hot dip galvanized to BS729. Stainless steel tie bars and nuts are available on request. Advantages • Accommodates up to 50 mm / 2” longitudinal adjustment. • Allows for fast and simple maintenance of valves and pumps. • Simplifies future pipework modifications and reduces down time. • Installed with a spanner and a torque wrench, no special tools needed. • Absorbs vibrations. • Accepts some disallignment in straight pipe |

|

|||||||||||||||||||

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dismantling Joints - Simplify Pipeline Maintenance Effortlessly |

|

Discover the convenience of dismantling joints for your pipeline system. Our dismantling joints offer a seamless solution for efficient disassembly and removal of pipeline sections. Enhance Efficiency: Our dismantling joints are designed to simplify maintenance and repair processes by providing easy disconnection and reassembly. Forget about cutting or modifying pipes – our solution saves you time and effort. Flexible Performance: Equipped with flanged ends and an adjustable middle body, our dismantling joints ensure secure and leak-proof connections. They can accommodate slight misalignments and changes in pipe length, guaranteeing reliable performance. Say Goodbye to Welding: With our dismantling joints, you can minimize the need for welding or threading. They streamline the installation process and reduce the risk of pipeline damage, making maintenance a breeze. Reliable Leak Prevention: Trust in the reliability of our dismantling joints to maintain the integrity of your pipeline system. Our sealing mechanism ensures leak-free connections when reassembling, providing peace of mind. Versatile Applications: Whether it’s water supply systems or industrial pipelines, our dismantling joints are suitable for various applications. They are available in different sizes, materials, and configurations to meet your specific requirements. Upgrade your pipeline maintenance with our efficient dismantling joints. Streamline processes, ensure reliability, and save valuable resources. Experience the difference today |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|