Impeller pump with motor, cable and plug, flow rate 14l/min, 230 V

Availability: 1 week

|

|||||||||||||||||||||||||||||||||

|

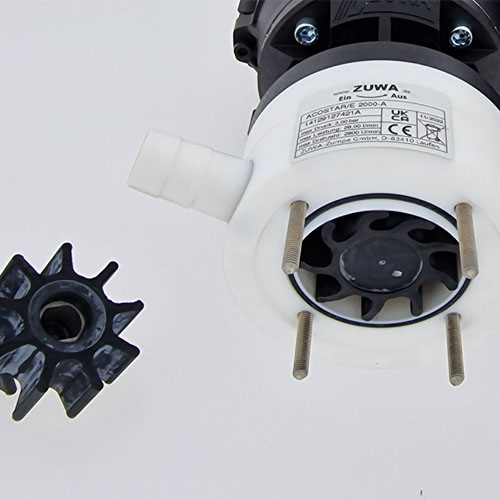

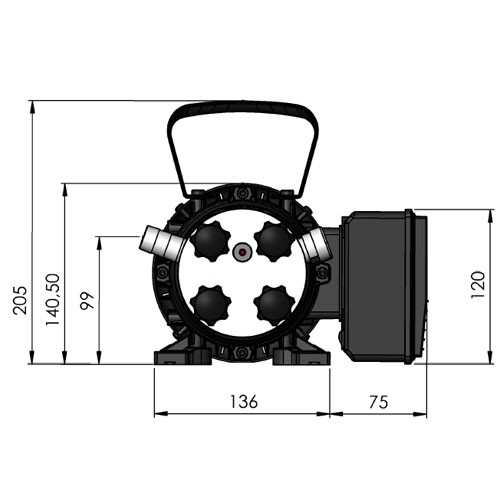

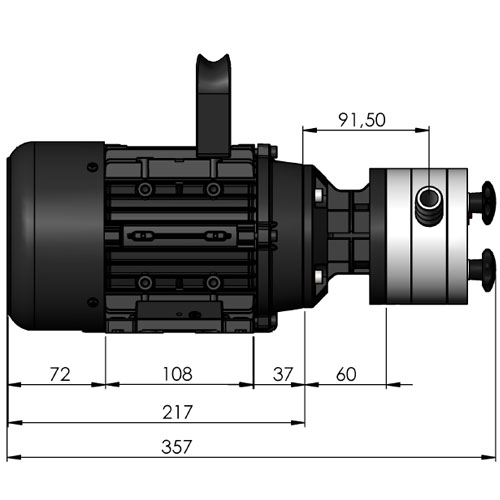

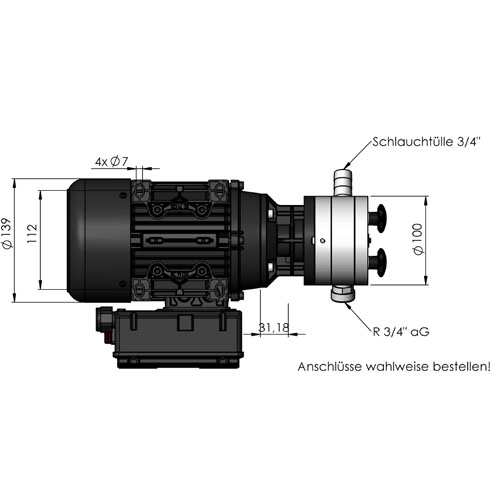

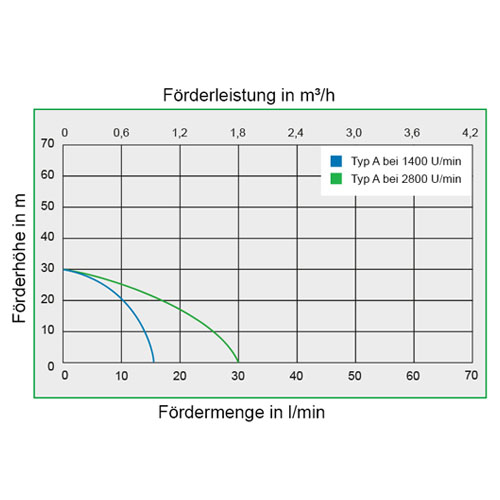

Acostar/E 2000-A, 1400 min-1, 230V Impeller pump with motor, cable and plug -max. flow rate (l) 14 l/min -max. Delivery pressure 3 bar -inlet/outlet 3/4" aG (Art. 11012107) -impeller EPDM -material bush Hastelloy C22 -shaft Acostar 18mm, with shaft bushing, 2.4602 (Hastelloy C22) -shaft seal EPDM -rod seal EPDM -Pump housing material PTFE -With dry-running protection 60° C -With star knobs -With bellhousing Electric motor Rated voltage (AC) 230 V, rated frequency 50 Hz rated power 0,37 kW, rated current (AC) 3,2A max. speed 1400 min-1 Starting capacitor 40µF, operating capacitor 16µF Material motor shaft 1.4104 Protection class IP55, operating mode S1 Motor protection (therm.) 130 Optional: Hose nozzles 3/4" (Art. 11012106) |

|

||||||||||||||||||||||||||||||||

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||

DRY SELF-PRIMING IMPELLER PUMP |

|

ZUWA impeller pumps are particularly easy to maintain and inexpensive to run. Due to the flexible impellers, they are insensitive to solids in the medium and can pump even highly viscous liquids. The different materials of the components (pump housing and flexible impeller) as well as the possible drives result in a wide range of pumps. This system makes our impeller pumps suitable for almost any conceivable application. Our own in-house production and workshop enable us to carry out special requests, custom-made products and repairs at any time. We offer housings made of aluminum, stainless steel and plastic. |

|

|

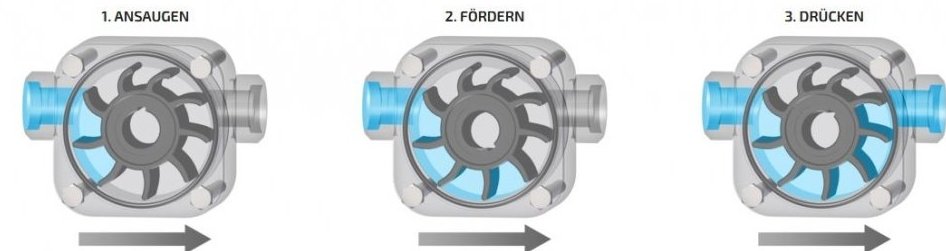

The replaceable impeller wheel is available in the following material: NBR, EPDM, CR, FKM, FPM and TPU. Our flexible impeller pumps can be used with different drives: with electric motors, air motors, V-belt drive, hydraulic motors, with a drill or with a cordless screwdriver via adapter. How does an impeller pump work? The impeller wheel rotates in the eccentrically shaped housing, so that the bending of the individual blades creates a vacuum and fluid is drawn into the vacuum. In this process, the fluid itself serves as lubrication for the impeller in the housing. To avoid possible damage to the pump, each ZUWA impeller pump can be equipped with an electronic dry running protection. |

Advantages of the impeller pump |

| Dry self-priming

A major advantage of the impeller pump is that it does not need to be filled before start-up. The pumps are dry self-priming up to a depth of 3 meters. Only at a suction depth of more than 3 meters is filling necessary. The maximum suction depth is 7 meters. Powerful The delivery rate of ZUWA impeller pumps ranges from 3 to 730 liters per minute. Containers can be emptied almost to the last drop. Gentle The pumping is pulsation-free. Air can be conveyed in small quantities. Versatile Can be used for a wide variety of liquids and applications. Materials of impeller, seal and pump housing can be selected according to the application. |

and adapt to the requirements. Motors are available with alternating, three-phase and direct current and with different speeds.

Reliable All pumps are tested in continuous operation in our workshop. High-quality materials guarantee a long service life. Easy to maintain Assembly / disassembly of the casing and replacement of the impeller are easy and quick. Spare parts are available separately. Low operating costs! Robust Impeller pumps also handle highly viscous liquids such as oil or honey (up to 20,000 mPas), as well as liquids with solids. The maximum permitted liquid temperature is 90°C. A dry run of up to one minute is tolerated. |

THE RIGHT IMPELLER FOR EVERY APPLICATIONNBR /acrylonitrile butadiene rubber (Perbunan®, Buna-N®): For water, antifreeze, heat transfer media, mineral and vegetable oils, greases. High impact elasticity and good mechanical strength good for applications with high pressures - up to a maximum of 5 bar. EPDM /Ethylene Propylene Diene Rubber (Keltan®, Buna EP®): for high temperatures, for acids and alkalis, high elasticity and very good mechanical resistance. CR /chloroprene rubber (Neoprene®, Bayprene®): Preferred for use with food, flame retardant, tear resistant, durable. FKM or FPM /Fluoro rubber (Viton®, Fluorel®): For oil, diesel, fuel oil, palm oil, soybean oil, acids and oil-based wood preservatives, very good chemical resistance, low mechanical strength. TPU for water, mineral and vegetable oils, diesel, heat transfer media, antifreeze and numerous chemicals, extremely tear-resistant and very good mechanical strength (not for abrasive media), maximum media temperature 60°C, not suitable for left/right rotation. |

|

SummaryDiscover the advantages of impeller pumps for your applications. Impeller pumps are highly efficient and versatile devices used in a variety of industries, from the chemical industry to water treatment. With their robust design and reliable performance, impeller pumps are an excellent choice for many applications. The impeller, the heart of these pumps, is a rotating paddle wheel that draws in liquid and transports it through the pump. This design allows for a continuous and even flow of liquid, making impeller pumps suitable for high flow rates and pressures. A key advantage of impeller pumps is their ability to handle solids and particles. Because of the rotating impeller, these pumps can easily pump liquids with small solids content without becoming clogged. This makes them ideal for wastewater treatment applications where solids are often present. Another big plus of impeller pumps is their energy efficiency. Thanks to their design and the precise fit between the impeller and the pump housing, impeller pumps can minimize energy consumption while offering high performance. This results in cost savings and more environmentally friendly operation. Maintenance and servicing of impeller pumps is also simple and cost-effective. Due to their robust design, they are durable and rarely require repairs. When necessary, wear parts can be easily replaced to further extend the life of the pump. When selecting an impeller pump, it is important to pay attention to the specific requirements of your application. Different impeller geometries and materials can be optimized for different fluids and operating conditions. In addition, many manufacturers offer customized solutions to ensure the pump is a perfect fit for your needs. Overall, impeller pumps offer an efficient, reliable and cost-effective solution for various industrial applications. Their ability to handle solids, energy efficiency, and ease of maintenance make them a popular choice for businesses worldwide. Discover the diversity of impeller pumps and benefit from their performance in your industry. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|