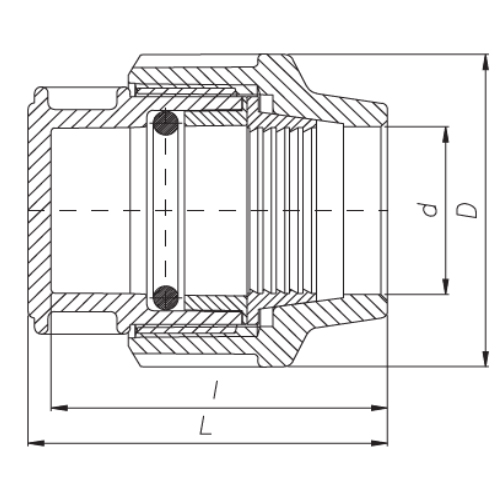

PP Compression fittings type UNIDELTA for PE pipes, end cap

Delivery time: 2-3 working days

|

||||||||||||||||||||

|

Unideltas compression fittings and tapping clamps are specially designed for connecting polyethylene pipes with outside diameters between 16mm and 110mm (200mm for tapping clamps) and are compatible with all PELD, PEHD, PE40, PE80, PE100 pipes manufactured in accordance with EN 12201, ISO 4427, ISO 14236, ISO 13460, DIN 8074 standards. They are normally used for the transportation of drinking water and liquids with a pressure of up to 16 bar and for general applications. Thanks to the properties of their materials, the fittings are resistant to attack by numerous chemical substances and UV rays. Unideltas universal fittings can be used to connect metric PE pipe systems with existing pipes of any material and outside diameters between 15 mm and 34 mm. |

|

|||||||||||||||||||

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PE pipe systems - maximizing performance and sustainability |

|

Polyethylene Pipe Systems, commonly known as HDPE, offer a multitude of advantages for your piping needs. With its exceptional durability, flexibility, and resistance to corrosion, HDPE pipe outperforms traditional metal and plastic piping systems. Let’s explore the remarkable characteristics that make HDPE the preferred choice for long-lasting and cost-effective piping solutions. Unmatched Corrosion Resistance: Say goodbye to the costly problems associated with rust and corrosion. Unlike metal pipes, HDPE does not rust, rot, or corrode. Its resistance to biological growth ensures extended service life and significant cost savings. Flexible, Ductile, and Fatigue-Resistant: HDPE pipe is not rigid but rather flexible and ductile, making it highly resistant to fatigue. It can handle occasional surge events common in water distribution systems, resulting in fewer disruptions and superior performance. In fact, HDPE’s flexibility often allows for the use of thinner walls compared to other plastic pipes, maximizing efficiency. Longevity and Reliability: Count on HDPE for a durable piping infrastructure. With a service life estimated between 50 to 100 years, HDPE delivers long-term reliability, reducing maintenance and replacement costs. Its proven track record in the natural gas industry for over 40 years speaks to its exceptional performance. |

|

Leak-Free Joints: HDPE piping systems can be joined using heat fusion, creating permanent, leak-free connections. This reliable fusion process has been used successfully in the natural gas industry and can be easily learned by trained personnel. Additionally, HDPE pipe can be joined using Stab or Mechanical Fittings, providing versatility for various applications. Trenchless Installation: Embrace eco-friendly trenchless technology for minimal disruption during installation. HDPE’s flexibility, tensile strength, and abrasion resistance make it an ideal choice for trenchless installations under environmentally sensitive areas such as creeks, roads, and right-of-ways. With reduced ground disruption and cost-effectiveness, HDPE ensures efficient pipeline installation. Pipeline Rehabilitation: Revitalize aging pipelines with HDPE through slip lining and pipe bursting techniques. These methods enable cities to rehabilitate or replace older infrastructure, improving functionality and increasing capacity. HDPE’s resilience ensures a reliable and long-lasting rehabilitation solution. Sustainability: HDPE’s eco-friendly nature adds another layer of appeal. Its manufacturing process requires less energy compared to non-plastic pipes. The lightweight design reduces transportation costs and environmental impact. The fusion joining method minimizes the need for additional fittings. Moreover, HDPE does not emit hazardous toxins during production or use, making it a safe and sustainable choice. It can also be recycled for non-pressure piping applications, promoting a circular economy. Choose HDPE pipe systems to maximize performance, sustainability, and cost-efficiency in your piping projects. Experience the advantages of this versatile and reliable solution that ensures long-term success while minimizing environmental impact. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|