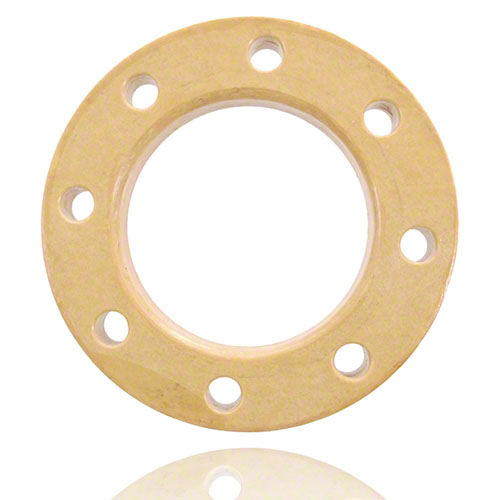

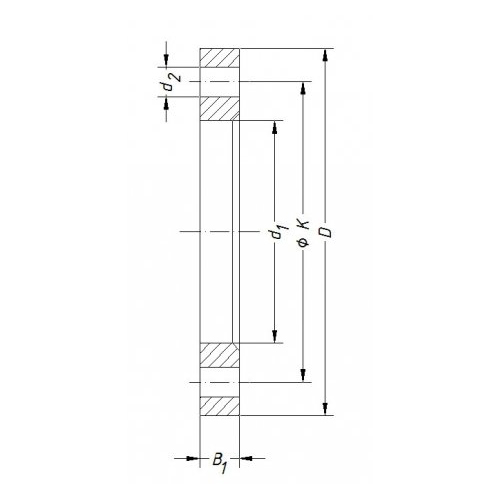

FRP- Backing Rings, according to DIN 16966-T6

delivery time: Lagerware freibleibend

|

| - according to DIN 16966 - Part 6 - Flange connection dimensions correspond to DIN 2501 part 1 Flange connection dimensions comply with DIN 2501 Part 1, PN 10 All versions also available in white on request |

|

|

||||||||||||||||||||||||||||||

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Breathing Quality with Efficient FRP Pipe Systems |

|

Glass Fiber Reinforced Plastic (GFRP), also known as GFK (Glasfaserverstärkter Kunststoff) in German, is a composite material composed of plastic resin and fibrous reinforcing material. The reinforcing material consists of glass fibers impregnated with unsaturated polyester resin (UP) or vinyl ester resin from the duroplast group. In Germany, the vinyl ester resin is officially identified as phenactylate resin, which is based on bisphenol A for types such as Derakane 411-350 or Distrotone VE 100, and on novolac resin for sorts like Derakane 470-300 or DION 9400. Before processing, these resins are viscous solutions of unsaturated polyesters dissolved in copolymerizable monomers (styrene). The final GFRP product is a combination of this plastic material and glass fibers. It is crucial to ensure proper impregnation of the glass fibers with resin. To achieve this, radicals (peroxides) are added to the liquid resins before impregnating the fibers, initiating the reaction and transforming the resin from a liquid state to a cross-linked state. During the curing process, no other byproducts are produced, but some of the solvent styrene may be released. The process time typically ranges from 15 to 45 minutes and can be adjusted using accelerators and/or inhibitors. The recipes, including the three components (hardener, accelerator, and inhibitor), are mixed individually based on weather conditions, required processing time, and specific processing requirements. Depending on the recipe, an exothermic hardening reaction starts within approximately 30 to 120 minutes, generating heat. This reaction leads to the hardening of unsaturated polyester resins through copolymerization, resulting in the formation of cross-linked substances. The polyester molecules form network structures with the styrene. A product manufactured in this way cannot be liquefied by heating and is not soluble in solvents (duroplast). DIN 16 966 regulates the specific designs, quality, and inspection of UP-GF fittings. This includes criteria such as negative pressure load, layer structure and glass contents, styrene content, surface quality, chemical resistance, adhesion and rigidity, hygienic and toxicological safety, fire behavior, dimensions, inspection, and short-time internal pressure tests. In addition to UP-GF pipe systems, Kwerk GmbH provides UP-GF lining materials for fittings according to pipe type B. Our delivery program includes: - PVC-U: Plasticizer-free polyvinyl chloride as per DIN 8061, color grey - PVC-U: Plasticizer-free polyvinyl chloride as per DIN 8061, color red - PVC-C: Chlorinated polyvinyl chloride as per DIN 8080 - PE-HD: High-density polyethylene as per DIN 8075 - PP: Polypropylene as per DIN 8078 - PVDF: Polyvinylidene fluoride Our UP-GF fittings are defect-free, ensuring no air bubbles or cracks. The laminate structure according to DIN 16966 is guaranteed for the entire length. Upon request, alternative UP-GF structures are also available. During the manufacture of UP-GF, all sealing surfaces and seams are properly laminated. With nearly 40 years of experience in producing and applying UP-GF fittings and connections, our team is ready to answer any additional questions. Simply give us a call at: 0049 2602 999730. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|