Spare blade for beveling tool

delivery time: 2-3 days

|

| Spare blade for beveling tool 900.791.10 |

|

|

||||||||||||||||||||||||||||||

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||

Plastic Pipe Systems - High-quality solutions for industrial pipeline construction |

|

ABS Pipe Systems - Versatile solutions for demanding applicationsABS pipes offer high temperature resistance ranging from -40°C to +60°C, depending on the medium and operating conditions. At Kwerk, we use special adhesive from the renowned company DURAPIPE to securely join ABS pipes. Our range includes ABS pipes with diameters ranging from d 16 mm to d 315 mm. The pressure rating is limited to 10 bar/8 bar. Our ABS fittings are divided into various categories and application fields. ABS solvent-weld fittings have a solvent socket on both ends. ABS transition fittings are either equipped with a solvent socket and a threaded side or a solvent socket and an internal or external thread. ABS threaded fittings have threads on both ends. Our range also includes a variety of ABS valves such as ABS ball valves, ABS diaphragm valves, ABS ball check valves, ABS air vent valves, and ABS shut-off valves. We place great emphasis on brand quality for our pipes, fittings, valves, and accessories. Our products cannot be compared to cheap suppliers from other regions of the world. The certifications speak for themselves and make us a reliable partner in the industrial, chemical, and process engineering sectors. We would be happy to provide you with a free quote upon request. Acrylonitrile-Butadiene-Styrene (ABS) is an amorphous thermoplastic with excellent mechanical properties, high chemical resistance, and high impact strength, especially at low temperatures. These properties make ABS a versatile material for a variety of applications. Trust in our ABS pipe systems for high-quality and reliable solutions. |

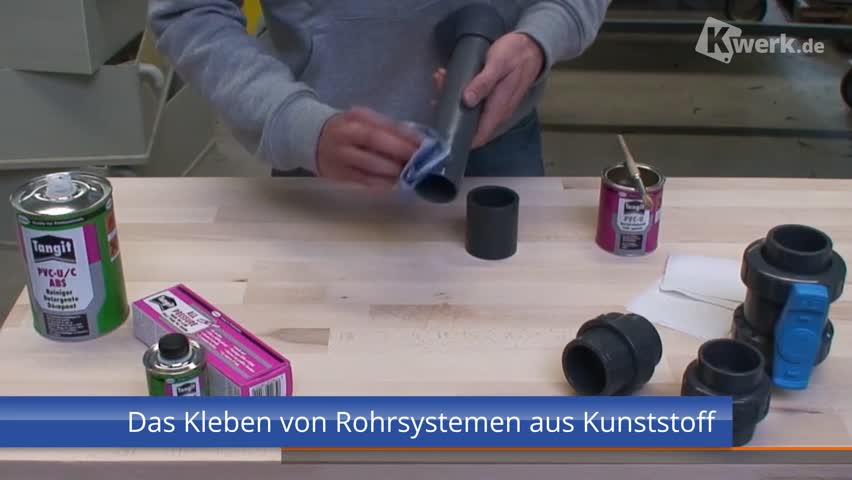

PVC-U Pipes, PVC-U Fittings, and PVC-U Valves - Reliable Solutions for Piping SystemsPVC-U pipes are ideal for connecting and distributing flow rates in piping systems. Depending on the nominal size, they are designed for specific operating pressures, which also depend on temperature and media concentration. The different pressure ratings of PVC-U pipes can be effectively bonded using Tangit adhesive from the renowned company Henkel. When bonding PVC-U pipes, it is important to follow the basics of the DVS bonding process. Bonding PVC-U pipes requires expertise in handling plastic piping systems. The bonding surface is determined by the Z-dimension in the PVC-U fitting. PVC-U fittings, like PVC-U pipes, are used for connecting and distributing flow rates in piping systems. At Kwerk, we differentiate between PVC-U solvent-weld fittings. These fittings have a solvent socket or a solvent spigot at one end. PVC-U transition fittings have a solvent socket or a solvent spigot on one side and an internal or external thread on the other side. PVC-U threaded fittings have internal or external threads on both ends. The PVC-U ball valve for water technology serves as the basic model for further variations of PVC-U ball valves. At Kwerk, you will find a wide range of PVC-U valves, including PVC-U diaphragm valves, PVC-U check valves, PVC-U ball check valves, PVC-U strainers, PVC-U angle seat valves, PVC-U laboratory valves, PVC-U shut-off valves, and PVC-U intermediate flanged valves, all made of high-quality PVC-U. We place great emphasis on brand quality for our PVC pipes, fittings, valves, and accessories. Our products cannot be compared to cheap suppliers from other regions of the world. The certifications speak for themselves and make us a reliable partner in the industrial, chemical, and process engineering sectors. We would be happy to provide you with a free quote upon request. Trust in our PVC pipes, PVC fittings, and PVC-U valves for high-quality and reliable solutions in piping systems. Safe Solutions for Industrial Piping Systems - PVC-C by KwerkOur PVC-C pipes, PVC-C valves, and PVC-C fittings are designed for water flow and have allowable operating pressures. These values are based on a safety factor of 2.5 and a service life of 25 years. You can find the pressure-temperature diagram in the "PVC-C Piping Systems" section in the dropdown menu for detailed information. PP-GF Piping Systems (Glass Fiber Reinforced Polypropylene) - Robust and Chemically Resistant SolutionsOur PP-GF piping systems are made of polypropylene reinforced with 20% polypropylene fiber borosilicate glass type "C". This material exhibits excellent mechanical resistance, high dimensional stability, and resistance to temperatures ranging from -10 °C to 100 °C. Graphite pigments and UV stabilizers are added to enhance UV resistance. Additionally, our PP-GF valves have ATEX certification, allowing their use in explosive environments. Kwerk offers an extensive range of high-quality PP-GF valves that meet the highest standards. We are committed to providing reliable products, and our PP-GF piping systems are designed to meet the demanding requirements of various industries. Quality and Diversity in PP Piping Systems - Explore the Range by KwerkPP pipes and PP fittings are made from the material PP-H (Polypropylene Homopolymer). Compared to other polypropylene materials (PP-R and PP-C), PP-H has the advantage of having the highest modulus of elasticity and the highest tensile strength. In our product range, we offer a wide variety of PP pipes. Our PP fittings are divided into the following categories and application areas. Discover our PP fittings for socket fusion welding, PP fittings with a short design for butt fusion welding, and PP molded fittings for spiral welding. Our PP valves are categorized as PP ball valves, PP diaphragm valves, PP strainers, PP check valves, and PP butterfly valves. All these high-quality PP fittings can be integrated into a piping system using various welding methods. Learn more about the outstanding properties of PP piping systems and their welding techniques. Welding PP piping systems allows for easy installation of new systems and modification of existing systems. As a reliable partner, we offer you welding methods approved according to DVS 2207- Part 11: socket fusion welding (HS), butt fusion welding (HD), and spiral welding (HM). Trust in the quality and diversity of PP piping systems with Kwerk. PP-R Piping Systems - Robust and Corrosion-Resistant Solutions for Your InstallationsPP-R piping systems are characterized by their high strength under internal pressure and temperature stress. They are corrosion-resistant and highly chemically resistant. At Kwerk, you will find high-quality PP-R pipes and PP-R fittings that are primarily connected through welding, ensuring a durable and homogeneous material connection. Our plastic pipes and fittings made from PP-R offer you all the advantages that have proven themselves in various industries and installation technologies for decades. Especially the excellent corrosion resistance guarantees a long service life of installation pipelines in building services, without the concern of pipe damage. Therefore, polypropylene is a great choice for the installation of piping systems for both cold and hot water. Opt for robust and corrosion-resistant PP-R piping systems and trust in the proven solutions by Kwerk for your installations. PE Piping Systems for Reliable Drinking Water Supply and Wastewater Technology - MADE IN GERMANYPE pipes have become indispensable in the field of drinking water supply and wastewater technology. Especially in underground pipeline construction, particularly in Northern Germany with its sandy soil conditions, PE pipes are highly popular. The material PE 100 is known for its excellent resistance to a wide range of acids and alkalis. While polyethylene is conditionally resistant to hydrocarbons, chlorine, and ozone, the chemical resistance depends on various factors such as operating temperature, operating pressure, and other influences. Thanks to continuous development, gas pipelines are now successfully installed using PE pipes. To prevent damage to the pipe surface, the PE pipe is bedded in sand according to common laying guidelines. Pipe and raw material manufacturers are constantly working on improving the material qualities, resulting in a variety of PE pipes available for different applications. PE has now replaced the material PVC-U in plant engineering, such as after the Düsseldorf airport fire. Due to their technological properties, PE pipes and PE fittings are also highly popular in plant engineering. Different types of PE fittings are used for various applications and processes. In underground pipeline construction, fittings with long welding necks are primarily used to connect PE fittings with heating coil fusion sockets. The butt fusion process is also applied to these long fittings. Another widely used technique is the connection of PE pipes with clamp connectors made of PP, which are approved for drinking water supply and provide additional safety. In plant engineering and traditional pipeline construction, PE fittings with short design are used, which are 100% installed and welded using the butt fusion process. Kwerk.de offers a wide range of tools, flanges, and welding systems for the secure connection of PE piping systems. We place great importance on delivery and quality MADE IN GERMANY. Our products and associated manufacturers also provide extensive technical support. Feel free to contact us with any questions. We are here to assist you. PVDF - The Reliable Material for Demanding Applications in Chemical and Process EngineeringPVDF is a material with exceptional resistance to acids, organic liquids, and UV radiation. Its main application is in chemical and process engineering. Thanks to its high purity, PVDF is also used in ultra-pure water and deionized water systems for the semiconductor and photovoltaic industries. PVDF pipes, fittings, and valves are made from high-quality PVDF SOLEF® resins that offer excellent properties for industrial applications. To make your search easier, we have organized our valves in the navigation menu. Here you will find the PVDF ball valve, PVDF diaphragm valve, PVDF check valve, and PVDF butterfly valve. PVDF is a thermoplastic construction material with a fluorine content of approximately 59%. PVDF is formed through the polymerization of the monomer vinyl fluoride, resulting in a plastic with outstanding mechanical, physical, and chemical properties. It can be used in a temperature range up to 140°C. The PVDF resin from SOLEF® is a granulate that is free from additional additives such as thermal stabilizers, fillers, and processing aids. By avoiding such additives commonly used in other thermoplastic materials, the excellent properties of PVDF, such as its chemical resistance, are retained even after processing. This exceptional versatility in terms of pressure, temperature, and chemical environments makes PVDF the preferred material in the chemical and pharmaceutical industry, automotive industry, pulp and paper industry, and many other sectors. Take advantage of our online tools for sizing and our project inquiry tool to successfully implement your construction project. We look forward to receiving your inquiry and a successful collaboration. Please note that all the information provided above has been carefully prepared to the best of our knowledge. However, no legal obligation can be derived from the content. For more information, please click on the dropdown menu to the right of the article or contact us directly by phone. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|