ABS Butterfly Valve, Electrically actuated, FPM

delivery time: 3-4 days

|

|||||||||||||||||||||||||||||||||

|

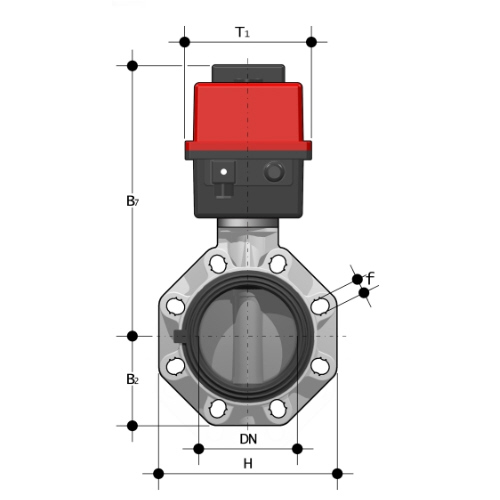

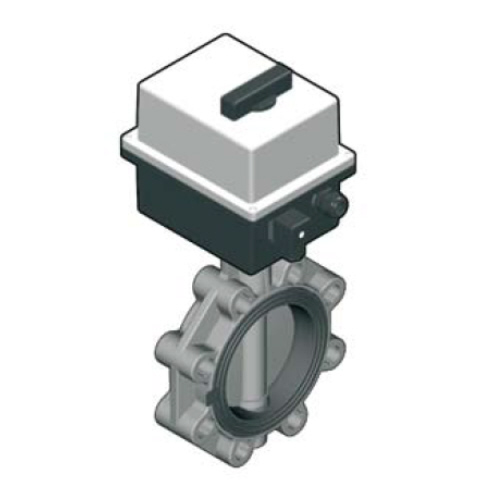

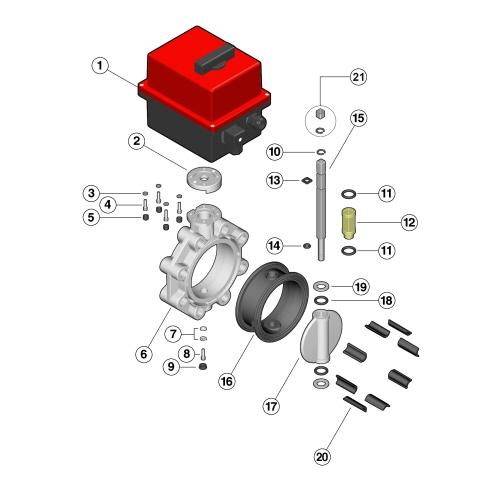

- Interchangeable Disk in PVC-U with through shaft, available in different thermoplastic materials: PP-H, PVC-C, ABS, PVDF - Overall dimensions of the valve in accordance with standard ISO 5752 (DN 40÷200 Medium Series 25, DN 250÷ 300 Long Series 16) and DIN 3202 K2 and ISO 5752 (DN 65÷200 K2, DN 250÷300 K3) - Can also be installed as an end line valve, bottom discharge valve or tank dump valve - Special Lug version PN 10 fully drilled to DIN 2501 or ANSI B16.5 cl.150 with molded-in AISI 316 stainless steel threaded inserts - Valve material compatibility (PVC-U) with water conveyance, drinking water and other food substances according to current regulations - Possibility of installing a manual reducer or pneumatic and/or electric actuators by applying an ISO standard drilling PP-GR flanges. - DN 40÷200 valve fitted with plate with rack in PP-GR. For actuated versions with flange drilled according to ISO 5211 F05, F07, F10. - DN 250÷300 valve, fitted with one-piece top flange in high mechanical strength PP-GR with mounting flange for internal components drilled according to standard ISO 5211 F10, F12, F14 - Electric actuator with plastic housing - Temperature: -10° C / +55° C Electrical connections Power supply: connector DIN 43650 3P+T(DN 40÷100) gland ISO M20 (DN 125÷300) Limit switches: gland ISO M20 Standard equipment: - Power supply: - 90-240V / 50-60Hz (AC), (24V AC / DC) without surcharge available - Emergency manual override - Visual position indicator - 2 auxiliary and adjustable limit switches FC1, FC2 (5A) - Torque limiter - Heating resistor (DN 125÷300) Options: - Positioner 4-20 mA or 0-10V - Fail safe unit - Heating resistor (DN 40÷100) - Feed back potentiometer 100 - 1000 - 5000 - 10000 Ohm - 4-20 mA position transmitter - 2 additional limit switches - IP67 or ATEX EEx |

|

||||||||||||||||||||||||||||||||

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Efficiency and Safety in Chemical Engineering: Experience the Power of Automated Plastic Valves and Precise Measurement Technology |

Automatic Valves Made of Plastic - Measurement and Control for Efficient and Safe ProductionIn chemical and process engineering, precise measurement and control of processes are vital to ensure efficient and safe production. Float flow meters are a reliable and accurate method for measuring the flow rate of liquids and gases, making them suitable for various applications. Plastic automatic valves, including ABS, PVC U, PVC C, PP, and PTFE valves, are widely used for regulating flow and pressure in pipeline systems. These valves offer excellent resistance to chemicals and corrosion, ensuring high operational safety. Pressure relief valves and pressure reducing valves ensure constant pressure regulation, while solenoid valves are employed for precise control of liquids and gases. Measurement technology holds significant importance in chemical and process engineering. Accurate measurements of temperature, pressure, and flow rate are essential for process control and maintaining product quality. Modern measurement technology provides high accuracy, reliability, and enables automated monitoring and control of processes. Overall, measurement and control are indispensable for efficient and safe production in chemical and process engineering. Float flow meters, plastic automatic valves, pressure relief valves, pressure reducing valves, solenoid valves, and modern measurement technology offer a cost-effective and reliable solution to meet industry requirements. At our webshop, we offer a comprehensive range of products, including float flow meters and automatic plastic valves. Our selection includes electric ball valves made of PVC U, PVC C, ABS, PP, and PVDF, as well as pneumatic ball valves constructed from the same materials. Additionally, our automated diaphragm valves made of PVC U, PVC C, ABS, PP, and PVDF are known for their durability and high quality. We also provide pressure relief valves and pressure reducing valves made from various plastics. We are actively seeking qualified suppliers and providers who can offer corresponding products in the field of plastic valves and measuring technology. These valves are essential in plant construction, particularly in chemistry and process engineering, and they serve a crucial role in the transportation of acids and alkalis. We have taken great care to ensure the accuracy and reliability of the information presented. However, we cannot accept liability for any consequences arising from the content. For further information, please refer to the drop-down menu on the right side of the article or feel free to contact us directly by phone. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|