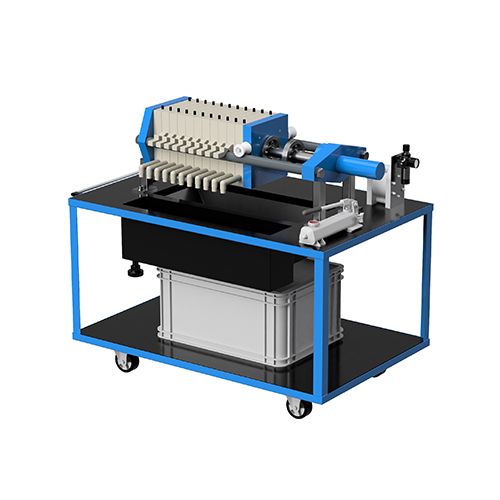

Laboratory filter press LFP 250-10

delivery time: 4 weeks

|

||||||||||||||||||||

|

Mobile laboratory filter press with open outlet, 10 chambers, designed as a round beam press with solid steel frame with epoxy primer and 2K paint. Mounted on a trolley with brakes. Plate format: 250 x 250 mm made of PP Cake thickness: 20 mm Chambers: 10 Filtration pressure: 8 bar Press capacity: 4.0 l Filter area: 0.92 m² Length: approx. 1250 mm Width: approx. 800 mm Height: approx. 1100 mm Weight: approx. 140 kg Includes: - Manual hydraulic system for closing the press (including ball valve, pressure gauge) - Compressed air diaphragm pump as feed pump - Connection set with relief ball valve, Bourdon tube chemical pressure gauge in the turbidity line for displaying the filtration pressure and hose. Includes all necessary connections. - Drip tray - Filter cloths (standard universal cloth FP-280-1410) - Collection container for filter cake - Documentation in German All components in contact with the filtrate are made of PP, EPDM and stainless steel 1.4571 Optional: - Transparent cover - Barrier plate to reduce the number of chambers |

|

|||||||||||||||||||

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Efficient laboratory filter presses for precise filtration requirements and reliable results |

|

Our laboratory filter presses have been specifically designed for use in laboratory environments, providing precise filtration of liquids. With their solid steel construction, they offer stability and durability. The press frames consist of sturdy uprights and crossbars securely bolted together. The filter press is mounted on a plastic substructure, allowing for easy transportation using common material handling equipment such as forklifts. The filter plates are made of high-quality polypropylene, enabling effective filtration and easy cleaning. The presses are operated using a hydraulic system that allows for opening and closing of the press. The hydraulic unit operates with a closing cylinder that securely seals the press and maintains the required filtration end pressure. A hand hydraulic pump with an integrated 2/2-way valve allows for precise control of the hydraulic pressure. Additionally, a ball valve is installed in the connecting line to prevent unintentional opening of the press during operation. For safety and protection of the filter press during transport and storage, a removable plastic cover is attached, fastened to the base frame with snap closures. The control side of the laboratory filter press is located on the hydraulic side, providing user-friendly operation. The filtrate outlet is centrally positioned at the bottom of the control side. Our laboratory filter presses offer a maximum allowable filtration pressure of 12 bar (15 bar) and require a minimum closing pressure of 405 bar at 12 bar filtration pressure. The maximum allowable closing pressure is 500 bar. The connection data includes a nominal size of DN 12 for the turbidity inlet (VA coupling 12 L) and a nominal size of PP hose nozzle Da 20 for the filtrate outlet. The filter press is equipped with a hydraulic closure that can be manually closed and opened by spring force. Trust in our many years of experience and expertise in the field of laboratory filter presses. For further information, we are at your disposal. Contact us today. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|