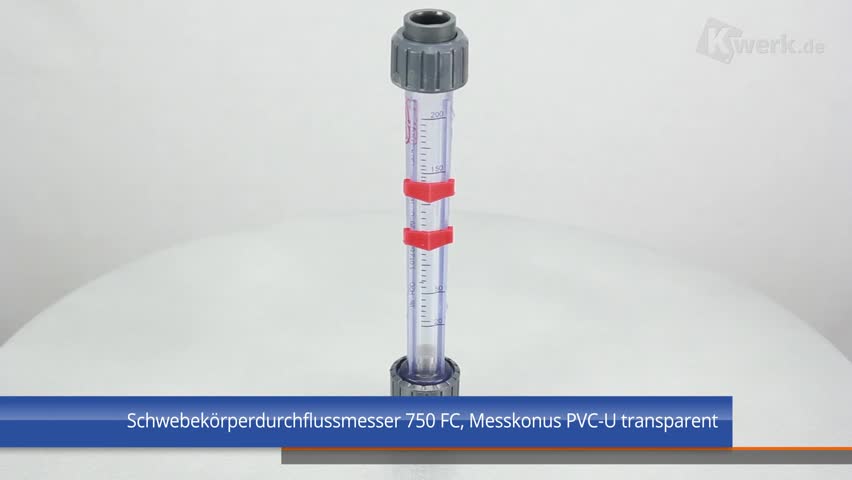

VARIABLE AREA FLOW METERSSERIES EASYFLOWVariable area flow meters are optical measuring devices for determination of the volume flow rate of fluids and gases in industrial pipework systems. The flow meter is radially removable and consists of a measuring cone with scale and an inside-lying float. Variable area flow meter - function The inside-lying float is lifted by the flowing liquid and the related flow speed until a balance is reached between the lifting force of the medium itself and the weight of the float. The volumetric result can now be read out on the scale in the measuring cone, on the top edge of the variable area flow meter. Ideally the variable area flow meter should be selected on the basis of the required flow rate being always located in the last third of the measuring cone. On request, the cone can be equipped with special scales for media with different densities. If the float is equipped with a magnet, for instance pumps and valves can be operated by attaching a break contact and a make contact at the measuring cone. Generally, variable area flow meters have a measuring range of 1:10. They are cost-effective measuring instruments for optical control of the volume flow. Our series „Easyflow“ is easy to handle and offers a wide field of uses for various media. The area of application can be enlarged by the implementation of accessories. „Easyflow“ is a series of variable area flow meters made of plastic, suitable for measuring the volumes of transparent liquids and gases passing through closed pipe systems. The flow meters can optionally be used for flow monitoring, by upgrading them with contact switches. For including them into the pipeline, a large number of connection variants is available. PVC screw fittings with gluing sleeves are offered as standard, however depending on pipe systems also screw fittings with threaded sockets, butt weld or socket weld ends and flanges are available. Advantages: • Large selection of measuring ranges • Large number of connection variants • Eight different nominal sizes • Five different measuring tube sizes • According to medium different measuring tube materials • Diverse float materials • Exchangeable measuring tubes • Radially removable with installed pipeline • Environmentally friendly design • High flexibility as well as customer-specific solutions • Short delivery times for standard and special scales Type for liquids: 700 und 750 FS Type for gases: 701 und 751 FC Measuring range for water: 1,5 l/h bis 50.000 l/h or/and % Standard media: water, 30% HCL, 30% NaOH, 50% NaOH, air 0 bar rel. Nominal sizes: DN 10, 15, 20, 25, 32, 40, 50, 65 Accessories: contact switch Accuracy class: Type 750: class 4 according to VDE/VDI 3513, sheet 2 Type 700: class 2,5 according to VDE/VDI 3513, sheet Missing data as well as other dimensions and materials on request. All items you will also find in our webshop. You can configure the flow meter yourself. |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Table measuring ranges |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| *Code 753 and gases on request

|

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|