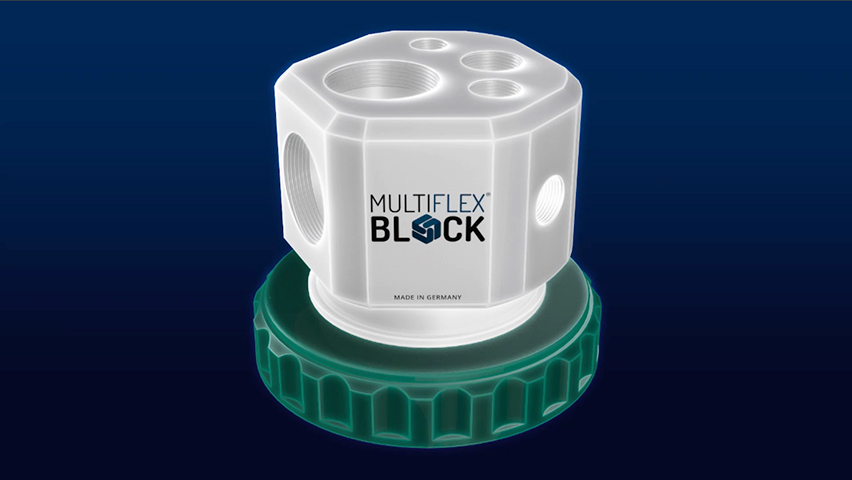

The MULTI FLEX BLOCK® is a state-of-the-art and multifunctional installation tool that is ideal for a wide range of applications. With its innovative design and outstanding features, it provides a flexible solution for installing connection components, couplings, valves, and measuring instruments in filling, extraction, and monitoring processes.

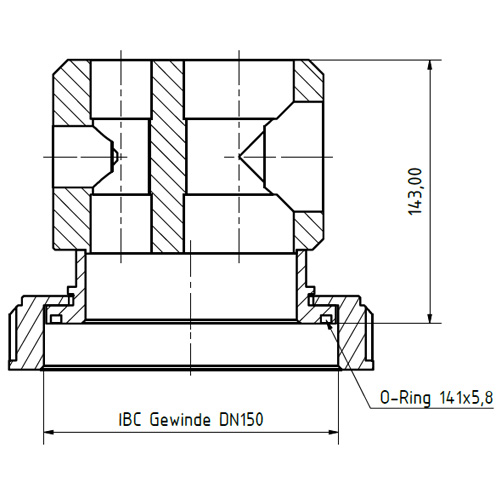

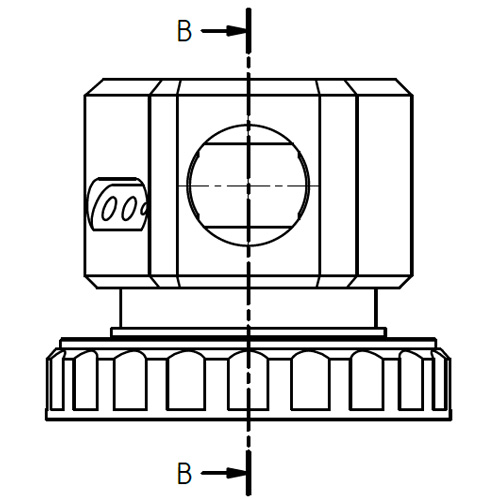

The key feature of the MULTI FLEX BLOCK® is its compatibility with various IBC (Intermediate Bulk Container) tanks. Its universal screw cap thread allows for easy and secure installation on IBC tanks from different manufacturers. This offers tremendous flexibility and greatly simplifies the installation process.

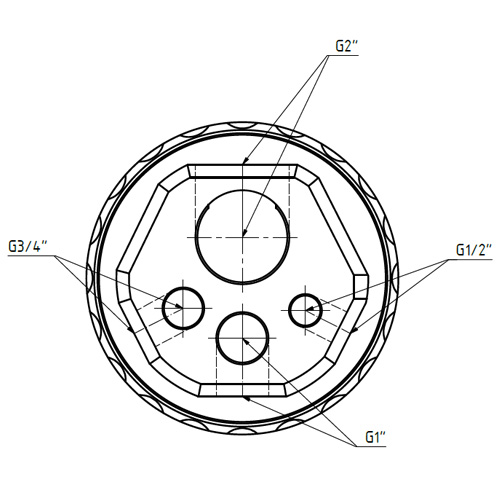

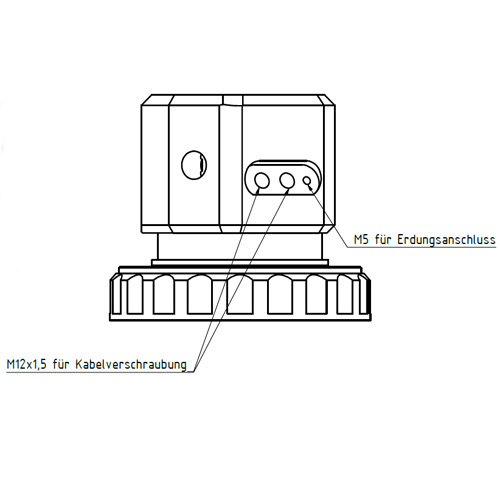

Another advantage of the MULTI FLEX BLOCK® is its versatility in adapting to specific requirements. With different connection threads on the block body, it enables the multifunctional installation of connection components to optimize filling, extraction, and monitoring processes. This flexibility allows for seamless integration of various components to enhance process control and monitoring.

Safety is paramount when using the MULTI FLEX BLOCK® . It is important for the plant operator to conduct a comprehensive hazard assessment when installing customer-specific attachments. This should include considering the necessary safety data sheets and providing appropriate training to the operating personnel. Only by adhering to all safety regulations can smooth and secure operations be ensured.

The commissioning of the MULTI FLEX BLOCK® is simple and straightforward. It should be securely and tightly screwed onto the IBC tank’s filling port. If necessary, a band wrench can be used to tighten the connection. The screw connections of the attachment components and blind caps should be tightened hand-tight to ensure a reliable seal.

To maintain the optimal performance of the MULTI FLEX BLOCK® in the long run, regular maintenance is essential. All functional connections should be checked for tightness, wear, and blockages. The maintenance instructions provided by the manufacturers of the customer-specific installations should be followed. Only through proper maintenance and servicing can optimal performance and reliability of the MULTI FLEX BLOCK® be ensured.

Lastly, it is important to adhere to the applicable safety regulations when cleaning the MULTI FLEX BLOCK® . Suitable washing stations and the use of cleaning agents compatible with the chemicals involved are mandatory to prevent harm to both personnel and equipment. Care should be taken not to use cleaning agents that may corrode the PE (Polyethylene) material and the sealing material. Thoroughly cleaning the surfaces and threads contributes to the long-term durability and functionality of the MULTI FLEX BLOCK® .

In summary, the MULTI FLEX BLOCK® is a reliable and efficient installation tool that allows for easy integration of connection components in filling, extraction, and monitoring processes. With its flexibility, ease of use, and high compatibility, it provides an optimal solution for a wide range of applications. Adhering to safety regulations, performing regular maintenance, and proper cleaning are crucial to ensuring optimal performance and longevity of the MULTI FLEX BLOCK® .

|