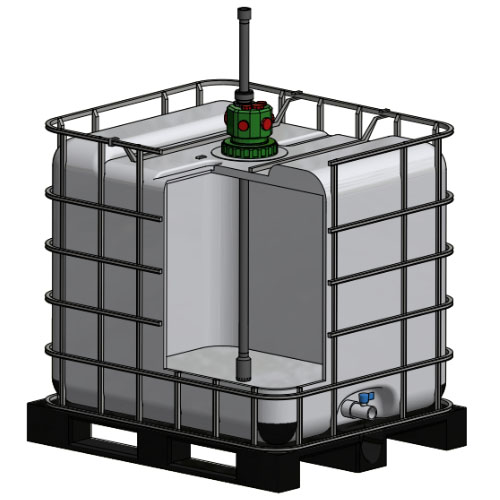

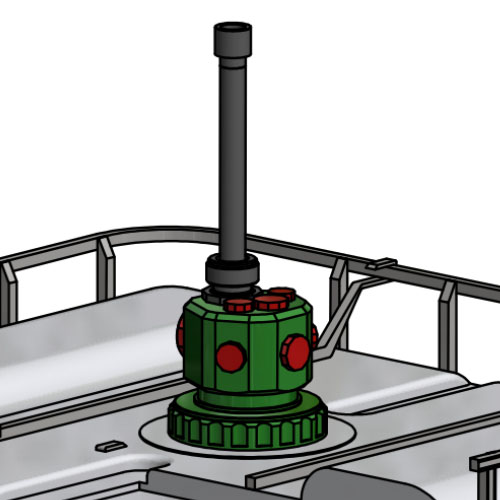

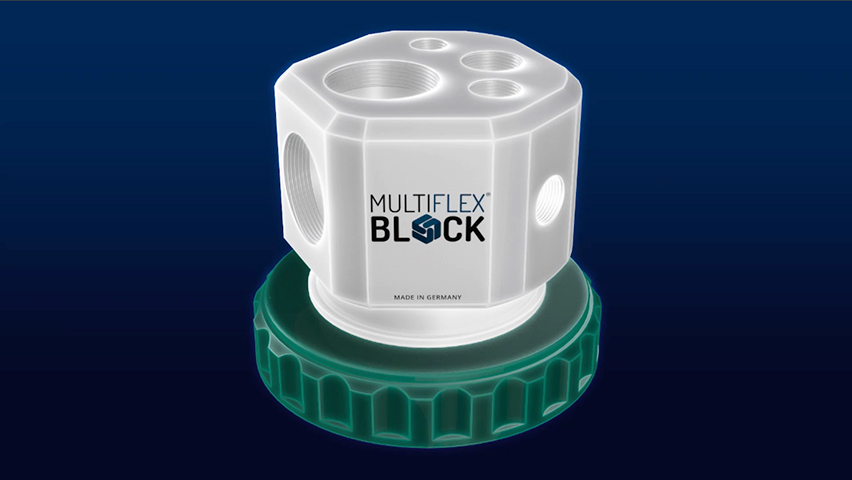

The MULTI FLEX BLOCK® is a versatile installation tool specifically designed for the filling openings DN150 and DN225 of Intermediate Bulk Containers (IBCs). With its universal screw cap thread for DN150 and special version with thread S245x6 for DN225, the MULTI FLEX BLOCK® can be securely attached to IBC containers from various manufacturers. This makes it a flexible solution for different applications. Before delivering the MULTI FLEX BLOCK®, it is recommended to check the thread compatibility of the DN150 filling openings on IBC containers manufactured outside the EU using a Kwerk sample cap. This ensures proper attachment of the MULTI FLEX BLOCK® to the containers. For larger filling openings like DN225 with the S245x6 thread, special versions of the MULTI FLEX BLOCK® can be used upon request.

The MULTI FLEX BLOCK® allows for versatile installation of connection components, couplings, valves, and measuring instruments for filling, dispensing, and monitoring processes. Thanks to the various connection threads on the block body, different components can be installed securely and efficiently. This enables multifunctional use of the MULTI FLEX BLOCK® and facilitates customization to specific requirements. With the MULTI FLEX BLOCK®, you get a reliable and flexible solution for your installation needs on IBC containers. Trust in the quality and versatility of the MULTI FLEX BLOCK® and benefit from efficient and safe handling of your filling, dispensing, and monitoring processes.

The use of electrically conductive plastic molded parts made of PE-el and PPs-el offers many advantages in the ATEX-MULTI FLEX BLOCK. These materials are lightweight, corrosion-resistant, and chemically inert, making them ideal for use in demanding environments. Thanks to their properties, they can be used in situations where metallic components are unsuitable due to corrosion or chemical reactions. Installation and maintenance are easy as they are compatible with conventional plastic piping systems. Electrically conductive plastic molded parts made of PE-el and PPs-el ensure the dissipation of electrostatic charges that may occur during operation. This is crucial in areas where electrostatic discharges could lead to dangerous sparks or ignition of explosive atmospheres.

For the use of MULTI FLEX BLOCKS in FOOD version, FDA-compliant plastic molded parts are suitable, specifically designed for use in food processing. They meet the stringent requirements of the US Food and Drug Administration (FDA) and provide a safe and hygienic solution for contact with food. The use of FDA-compliant plastic molded parts brings numerous advantages. They are food-safe, non-toxic, and tasteless, ensuring the quality and safety of food products. Additionally, they are chemically resistant to food and cleaning agents. When in need of FDA-compliant plastic molded parts, it is important to turn to trusted manufacturers or suppliers who have the necessary expertise and experience. This ensures that you receive high-quality and certified products that meet the requirements of your food processing application. Rely on FDA-compliant plastic molded parts to ensure the safety, hygiene, and quality of your food products. Depend on proven solutions that comply with the strict guidelines of the FDA and provide you with reliable and long-lasting performance.

The Chemical Vapor Separator for acid and alkaline exhaust air is another important accessory that can be installed on the MULTI FLEX BLOCK®. It helps capture and filter harmful vapors and gases during the filling and dispensing process, ensuring workplace safety.

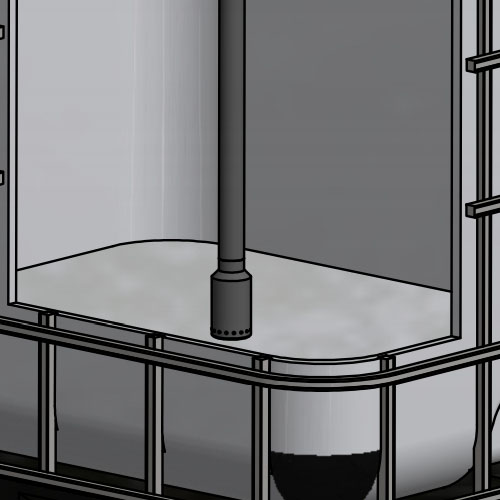

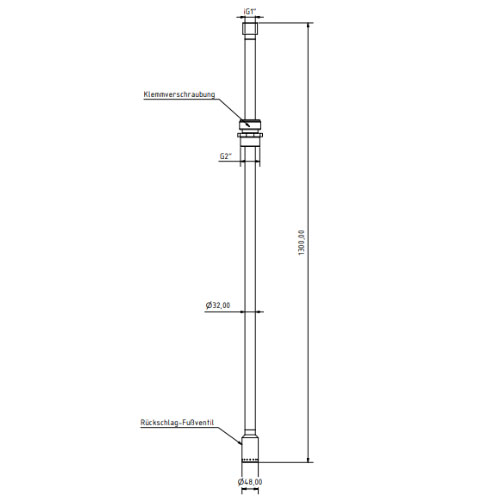

For top dispensing processes on IBC containers, suction lances are a practical accessory that facilitates access to liquids in the IBC. They allow for direct suction of the liquid from the container. Using suction lances in combination with pumps enables controlled and efficient liquid transfer. They are used for tasks such as transferring liquids, emptying tanks, sampling, or chemical dosing. The design of suction lances varies depending on the application area. There are suction lances made of different materials such as stainless steel or plastic to meet specific requirements. Additionally, suction lances can be equipped with accessories such as check valves, suction filters, and level switches to accommodate individual needs. When selecting a suction lance, consider the specific requirements of the application, such as the type of liquid, required flow rate, temperature resistance, and chemical compatibility.

An IBC adapter for the lower outlet of IBC containers is an important accessory that allows for a secure connection between the container and external systems. IBCs, or Intermediate Bulk Containers, are commonly used in the industry for the transportation and storage of liquids and bulk materials. The IBC adapter provides a reliable solution for controlled fluid transfer from the IBC container. It is available in various materials, sizes, connection types, and threads to meet individual requirements. Proper installation ensures a secure connection without leaks or fluid loss. They meet the demanding requirements of the industry, offer a long service life, and provide easy handling and flexibility in the use of IBC containers.

|