STATIC MIXERS MADE OF PLASTICStatic mixer - operating principle |

| Gases, aqueous liquids, high viscous liquids, liquids with significant viscosity differences as well as gases containing liquids are statically mixable. A static mixer made of plastic consists of internally arranged rows of plastic elements. We design and produce this inliner for static mixers in our workshop. In the open intersecting channels of a mixing element, the flow currents are divided into individual partial flow currents and then sheared off at the junction area of the channels. In the first mixing element inhomogeneity balances out two-dimensionally and in the following elements - twisted by 90° - three-dimensionally. The layout of a static mixer made of plastic is primarily influenced by the properties of the fluids to be mixed, especially viscosity and density, the volume flow, the quality of the mixtures, the installation length und the internal pipe diameter. The mixer length depends on the mixing grade and the miscibility of the fluids.

Kwerk GmbH also produces static mixers with injection point for fluid media. For this purpose the static mixer is equipped with an outlet socket, dimensions and design according to customerís request. Sometimes the static mixer is also called static blender. FOR THE RELATIVE MIXING LENGTH THE FOLLOWING VALUES ARE GENERALLY APPLIED:L/D= 1....3 for gases L/D= 3....5 for low viscous liquids L/D= 5....10 for high viscous liquids L/D= 10...15 for fluids with significant viscosity differences, e.g. gas/liquids THE PRACTISEKwerk.de offers a wide variety of static mixers made of plastic. Beyond our standard supply range we provide special solutions for the chemical industry and process engineering, made by practitioners for practitioners. The long-term practical experience on construction sites in Germany and abroad guarantees functional safety, combined with an extremely good price/performance ratio. We are a strong partner and attach great importance to a long-standing cooperation. |

|

|

|

DELIVERY PROGRAMM STATIC MIXER

|

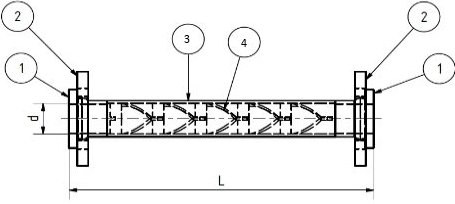

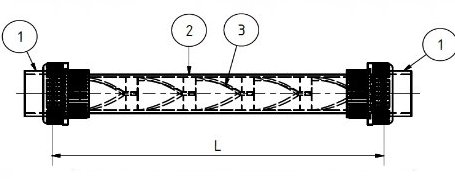

1.) union 2.) O-Ring seal 3.) pipe 4.) mixing element |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

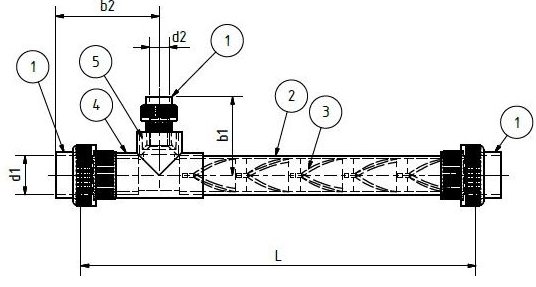

STATIC MIXER UPVC, UPVC TRANPARENT, CPVC SCREW CONNECTION SLEEVE DN 15 - DN 80WITH INJECTION NOZZLE 1.) screw connection with seal 2.) pipe 3.) mixing element 4.) T-piece 5.) reduction |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

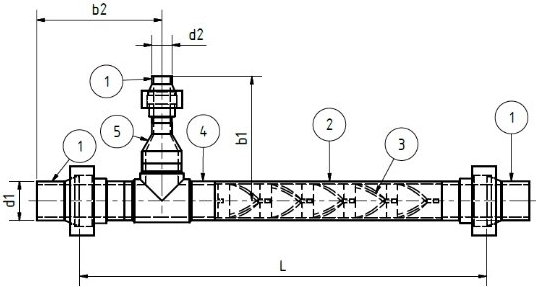

STATIC MIXER PE, PP, PVDF SCREW CONNECTION WITH BUTT WELDING CONNECTION DN 25 - DN 80WITH INJEKTION NOZZLE 1.) Screw connection with seal 2.) Pipe 3.) Mixing element 4.) T-piece 5.) Reduction |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

STATIC MIXER PVC U, PVC U TRANSPARENT, PVC C , PP-H, PE100 AND PVDF

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

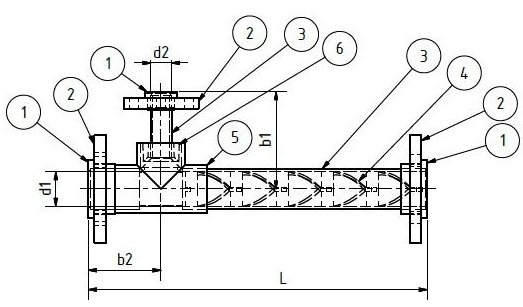

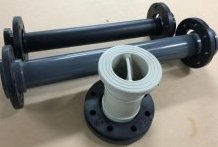

STATIC MIXER PVC U, PVC U TRANSPARENT AND PVC C FLANGED VERSION DN 15 - DN 65WITH INJEKTION NOZZLE 1.) Collar bushing 2.) loose flange PP with steel insert DIN 2501 3.) Pipe 4.) Mixing element 5.) T-piece 6.) reduction 7.) Pipe |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

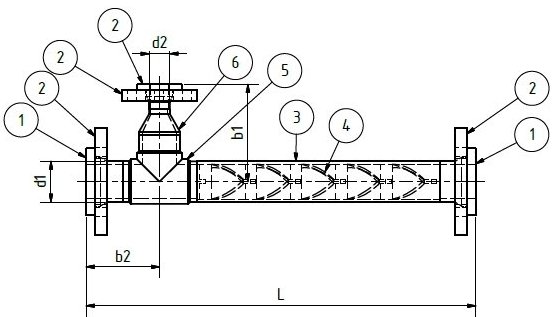

STATIC MIXER PP-H, PE 100 AND PVDF FLANGE DESIGN DN 25 - DN 65WITH INJEKTION NOZZLE 1.) stub end welding collar 2.) loose flange PP with steel insert DIN 2501 3.) Pipe 4.) Mixing element 5.) T-piece 6.) reduction |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

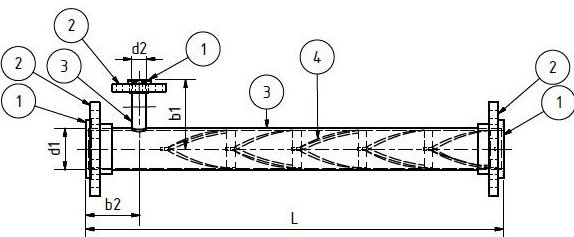

STATIC MIXER PVC U, PVC U TRANSPARENT AND PVC C FLANGED VERSION DN 80 - DN 100WITH INJEKTION NOZZLE 1.) Collar bushing 2.) loose flange PP with steel insert DIN 2501 3.) Pipe 4.) Mixing element 5.) Pipe |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

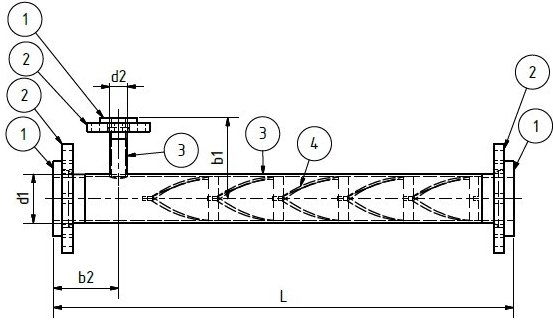

STATIC MIXER PP-H, PE 100 AND PVDF FLANGE DESIGN DN 80 - DN 200WITH INJEKTION NOZZLE 1.) stub end welding collar 2.) loose flange PP with steel insert DIN 2501 3.) Pipe 4.) Mixing element |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

STATIC MIXERS MADE OF PLASTIC - PICTURES FROM THE WORKSHOP - |

Static mixers - variants - |

Static mixer with injection point |

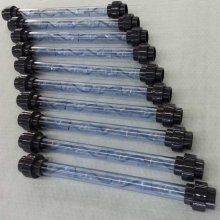

static mixer pvc transparent |

static mixers with PE injection point |

Static mixer made of PE with injection nozzle |

Static mixer made of PVDF with injection nozzle |

Static mixer made of PVC U TRANSPARENT |

Static mixer made of PVC U TRANSPARENT and PE-100 |

Static mixer made of PE-100 with injection nozzle |

|

|

|

|

|

|

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|