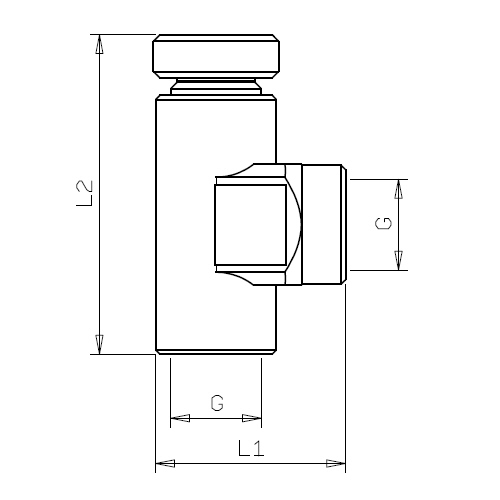

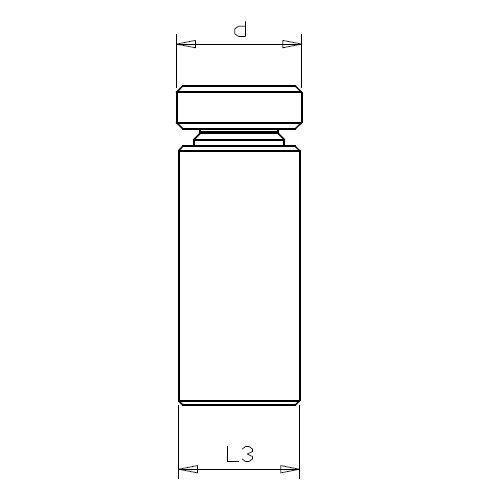

Needle valve made of PP with angle bore

Availability: immediately

|

| Needle valve for fine regulation of volume flows - By operating the adjusting screw, the medium is reliably throttled or shut off - Valves are on both sides with an internal threadn made for maximum flexibility during installation -Fitting connection accessories available (Adapter for butt-IR welding, screw connections, etc.) -Material of SpindelSeal FPM / Viton -suitable for media sampling (hose nozzle available as accessory) Pressure stage SDR 7.4, PN16 at 20 ° C Other dimensions and materials on request |

|

|

||||||||||||||||||||||||||||||

Information:

Information:

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Needle Valves made of plastic - Advantages, Applications, and Customizations |

|

Needle valves made of plastic offer both advantages and disadvantages compared to other materials such as metal. Advantages of plastic needle valves:- Corrosion resistance: Plastic valves withstand a variety of chemicals and do not corrode, making them ideal for use in aggressive environments. - Lightweight: Plastic valves are lighter than metal valves, making them easier to handle and transport. - Good insulation properties: Plastics are good insulators, making them suitable for applications with high temperatures or electrical currents. - Chemical resistance: Plastics are generally resistant to many chemicals, making them suitable for use in chemical and pharmaceutical industries. - Cost-effectiveness: Plastic valves are usually more cost-effective than metal valves. Disadvantages of plastic needle valves:- Limited mechanical strength: Compared to metal valves, plastic valves have lower mechanical strength and may break or get damaged when subjected to excessive stress. - Temperature limitations: Plastic valves have limited temperature resistance and can deform or melt at high temperatures. - Pressure limitations: Plastic valves are less suitable for use at high pressures compared to metal valves. Applications of plastic needle valves in the chemical, pharmaceutical, and process engineering industries:- Chemical dosing: Plastic valves allow precise dosing of chemicals in chemical and pharmaceutical industries. - Sampling: In process engineering, plastic valves can be used for the sampling of liquids and gases. - Cleaning processes: Plastic valves are resistant to cleaning agents, making them suitable for cleaning processes in the food and beverage industry. - Water treatment: Plastic needle valves are also used in water treatment and disinfection processes. Summary:Needle valves made of plastic have advantages and disadvantages in the chemical, pharmaceutical, and process engineering industries compared to other materials. Needle valves are ideal for use in aggressive environments and applications with high temperatures or electrical currents due to their corrosion resistance, lightweight, and good insulation properties. They are also resistant to a variety of chemicals, making them suitable for precise chemical dosing and sampling of liquids and gases. However, they have limitations in terms of temperature and pressure resistance as well as mechanical strength compared to metal valves. Nonetheless, plastic valves are an attractive alternative due to their cost-effectiveness. We offer plastic needle valves in various configurations, including through-hole with internal threads, through-hole with external threads, and an angled version with through-hole and internal threads. We customize our standard program to meet individual customer requirements. Needle valves find applications in the chemical and process engineering industries, including laboratory and pilot plants. If you have any questions about our plastic needle valves, feel free to call us or send your inquiries via WhatsApp or email. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|