Griffco injection valves are meticulously designed to ensure precise and accurate injection of chemical doses into the center of process streams. This strategic placement facilitates optimal mixing of the dose within the fluid, enhancing its effectiveness while also safeguarding against corrosion of the process pipe wall. Additionally, the integrated check valve effectively prevents any backflow of the process fluid up the feed line, further enhancing the reliability and efficiency of the system.

These valves are engineered with robust construction, guaranteeing their durability and reliability even during maintenance or servicing. With a wide range of sizes available, from 1/2" to 2" NPT or BSPT, or DN 15 to DN 50, Griffco injection valves cater to various system requirements. They can handle pressures up to 207 bar, ensuring their suitability for demanding industrial applications.

Griffco injection valves offer versatile customization options to meet specific needs. Multiple "check ball" options, including Stainless Steel, PTFE, and Hastelloy® C, are available, along with various tip configurations and liquid-contact materials. Seal options such as EPDM and FKM (Viton®) provide compatibility with different chemicals.

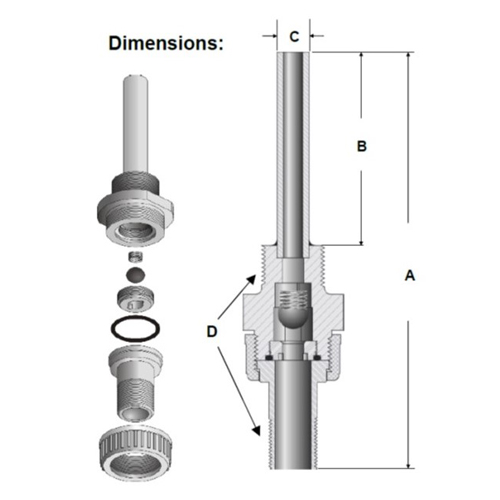

The valves feature a union connection interface as a standard, enabling convenient threaded or glued/welded socket connection options. They also offer flexible hose connection choices and fast and easy union disconnect for efficient servicing. With options for male and female threads, press-fit installation without welds, custom quill lengths, and a quill stiffener option for plastic construction, Griffco injection valves provide flexibility and adaptability to suit diverse installation requirements.

Materials used in Griffco injection valves include SS316 L, Alloy 20, Hastelloy® C, PVC, CPVC, PVDF, and PP. The connection options range from 1/2" to 2" MNPT or male BSPT, with plastic valves offering a union size of 1/2" to 2" or DN 15 to DN 50.

Griffco collaborates with strong partners to deliver specialized fittings for measurement technology and laboratory applications. The product range includes laboratory ball valves made of PVC U and PVDF, flow fittings made of PP for measuring parameters such as pH, REDOX, and temperature. Needle valves made of PVC U, PVC C, PE, PP, and PVCDF enable precise volume flow adjustment. Additionally, Griffco offers suction filters up to d 280 mm and sight glasses made of PVC U, PP, and PVDF up to d 160 mm, completing the comprehensive range of solutions.

Please note that while every effort has been made to provide accurate and reliable information, no liability can be derived from the content. For further information, please refer to the drop-down menu on the right or contact us directly. We will be happy to assist you.

|