Stainless steel pipe coupling type INSTAL, width 95, quality A2, SILICON BLUE sealing gasket

delivery time: 3-4 days

|

|||||||||||||||||||||||||

|

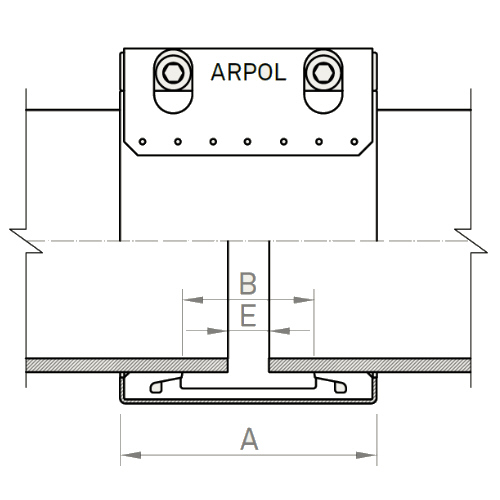

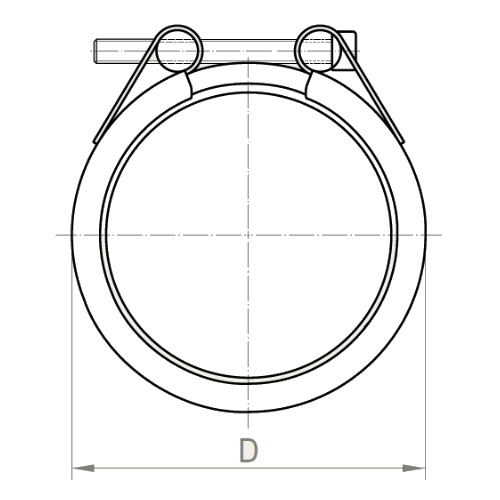

Flexible stainless steel pipe coupling for connecting pipes. Material quality A2 (V2A) - Housing AISI 304L, DIN 1.4307 - Screws AISI 304, DIN 1.4301 - Bolt AISI 304L, DIN 1..4307 - Anchoring rings AISI 302, DIN 1.4310 - SILIKON Blue sealing sleeve, suitable for drinking water and service water, temperature range: from -55 ° C - 200 ° C Explanations: E1 = Permissible distance of pipe ends without tape insert E2 = Permissible distance of pipe ends with tape insert AM = tightening torque PN = nominal pressure for shipbuilding with safety factor greater than or equal to 4 PS = continuous operating pressure DA = external diameter Dimensions and further design - see table. For a correct function of the pipe coupling, the installation instructions must be observed. Test pressure 1.5 x PS / PN Please note in the application, the other technical information in the pop-up menu or send us an inquiry. |

|

||||||||||||||||||||||||

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Connecting Excellence with Stainless Steel Precision |

|

Arpol is an internationally recognized manufacturer of stainless steel pipe couplings and connection technology. The company was founded in the early 1980s and has since earned a reputation for innovative and high-quality solutions in the field of stainless steel pipe connection technology. Arpol stainless steel pipe couplings are characterized by their reliability, flexibility, and easy installation. They are used in a variety of applications, ranging from industrial processing to building technology and infrastructure projects. One outstanding feature of Arpol stainless steel pipe couplings is their adaptability to different pipe diameters and materials. This provides a versatile solution for connecting stainless steel pipe systems. The installation of Arpol stainless steel pipe couplings is simple and does not require any special tools or welding. The couplings are simply placed around the stainless steel pipes to be connected and secured with screws or nuts. This allows for quick and efficient assembly, saving time and costs. Arpol stainless steel pipe couplings provide high tightness and resistance to pressure, vibrations, and temperature fluctuations. They ensure a secure and leak-free connection of stainless steel pipes, even under demanding operating conditions. Furthermore, Arpol stainless steel pipe couplings are known for their durability and maintenance-free operation. They are made of high-quality stainless steel and offer long-term performance without the need for regular maintenance or readjustment. Stainless steel also provides high corrosion resistance, ensuring a long service life for the couplings. Arpol offers an extensive product range, including various types and sizes of stainless steel pipe couplings, to meet the requirements of different applications. The company places great emphasis on quality and complies with international standards and certifications in the stainless steel industry. In summary, Arpol stainless steel pipe couplings are a proven solution for reliable connection of stainless steel pipe systems. They offer easy installation, flexibility, tightness, and durability, making them a preferred choice in various industries. V2A and V4A are designations for different types of stainless steel alloys. The letter "V" stands for "Verschleißfestigkeit" (wear resistance) in German, which translates to "wear resistance" in English, and the numbers "2" and "4" refer to the chromium content in the alloy. V2A stainless steel, also known as AISI 304 or 1.4301, mainly consists of iron, chromium (approximately 18%), and nickel (approximately 8%). This alloy offers good corrosion resistance and is suitable for use in many applications. V2A stainless steel is often used in areas that do not have direct contact with aggressive chemicals or saltwater, such as indoor environments, construction, household appliances, or food processing. V4A stainless steel, also known as AISI 316 or 1.4401, is an advancement of V2A stainless steel and contains additional elements such as molybdenum (approximately 2-3%) in addition to chromium and nickel. This gives V4A stainless steel even higher corrosion resistance, especially against chloride-containing media such as seawater or chemical solutions. Therefore, V4A stainless steel is commonly used in marine environments, the chemical industry, swimming pools, or applications that require high corrosion resistance. The main difference between V2A stainless steel and V4A stainless steel lies in their corrosion resistance. V4A stainless steel offers improved resistance to more aggressive environments, particularly chloride-containing media. When choosing between the two alloys, it is important to consider the specific requirements of the application, especially regarding the environment and the type of chemicals used. EPDM, FPM, Silicone, and NBR are abbreviations for different types of elastomers used in sealing technology and other industrial applications. Here are the differences between them:- EPDM (Ethylene Propylene Diene Monomer): EPDM is a synthetic elastomer with excellent resistance to weathering, ozone, UV radiation, and temperature extremes. It is also resistant to water, steam, acids, bases, and many chemicals. EPDM is commonly used in the automotive industry, construction, plumbing, and the food industry. - FPM (Fluoro Rubber, also known as FKM or Viton): FPM is a fluorinated elastomer with excellent resistance to high temperatures, chemicals, fuels, oils, and solvents. It exhibits high thermal and chemical stability and is therefore frequently used in demanding applications such as the chemical industry, oil and gas industry, automotive industry, and aerospace. - Silicone Rubber: Silicone is an elastomer known for its high temperature resistance, good electrical insulation, and excellent weather resistance. Silicone rubber is flexible, soft, and has good aging resistance. It is used in a variety of applications including the food industry, medical devices, electronics, lighting technology, and the automotive industry. - NBR (Nitrile Rubber, also known as Nitrile or Buna-N): NBR is a synthetic elastomer with good resistance to oils, fuels, solvents, and petroleum-based chemicals. It also has good mechanical strength and high abrasion resistance. NBR is commonly used in applications that require oil resistance, such as the automotive industry, oil and gas industry, hydraulic systems, and seals for industrial equipment. It is important to note that the selection of the appropriate elastomer depends on the specific requirements of the application, including the type of chemicals, temperatures, pressures, and other environmental conditions to which the material will be exposed. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|