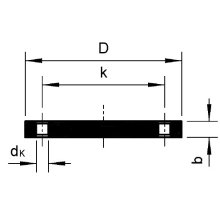

PVC U Transparent blind flange for pressureless applications

Delivery time: 2-3 business days

|

- CNC machined from sheet material - bolt pattern drilled according to PN 10, other versions possible on request - flange thickness (b) on request according to the customer - other materias on request *flange thickness b depending on the availability and size of the sheet material. For prices please use our configurator for blind- and loose flanges in the drop-down menu on the right hand side. |

|

|

||||||||||||||||||||||||||||||

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CNC Plastic Turned Parts for Demanding Applications in Chemical, Process, Pharmaceutical, and Food Technology |

|

In chemical, process, pharmaceutical, and food technology industries, components often require specific characteristics. CNC plastic turned parts offer numerous advantages in meeting these requirements. They are customizable, precisely manufactured, and exhibit high chemical resistance. Read on to discover the benefits of CNC plastic turned parts and their applications in chemical, process, pharmaceutical, and food technology industries. Advantages of CNC Plastic Turned PartsCNC plastic turned parts offer several advantages over conventional metal or other material turned parts. One of the major advantages is their chemical resistance. Plastics such as PVDF, PP, natural PP, PVC-C, ABS, PE, and PVC U exhibit resistance to many chemical substances and maintain their properties even at high temperatures. This makes them highly durable and suitable for challenging conditions. Another advantage of using plastics for CNC turned parts is the flexibility they offer in manufacturing. They can be easily customized and tailored to specific requirements. CNC plastic turned parts are precisely manufactured, ensuring high repeatability. They are well-suited for Applications of CNC Plastic Turned PartsCNC plastic turned parts find diverse applications in chemical, process, pharmaceutical, and food technology industries. They are used in the production of chemical plants, laboratory equipment, pumps, and valves. They are also employed in the food and pharmaceutical sectors, such as in the manufacturing of filling systems, dosing systems, and packaging solutions. Furthermore, CNC plastic turned parts are suitable for environmental engineering, electrical engineering, and many other fields where chemical resistance and precision are crucial factors. ConclusionCNC plastic turned parts provide a flexible, precise, and chemically resistant alternative to conventional metal or other material turned parts. They are indispensable in chemical, process, pharmaceutical, and food technology industries and find applications in various other fields. Our current range of fluid piping components includes:- PVC U, PVC C, PE, PP, and PVCDF inserts - PVC U, PVC C, PE, PP, and PVCDF threaded parts - PVC U, PVC C, PE, PP, and PVCDF threaded fittings - PVC U, PVC C, PE, PP, and PVCDF connections - Accessories - PVC U, PVC C, PE, PP, and PVCDF flanges/block flanges All the above information has been provided with the utmost care and knowledge. However, no legal claims can be derived from its content. For further information, please refer to the dropdown menu located to the right of this article or simply give us a call. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|