UPVC Pipe Systems - General characteristics |

|

The company Akatherm FIP GmbH located in Mannheim is a leading provider of UPVC-pipe components with long-term experience in plastic pipe systems. The quality of our products and the services provided by Akatherm FIP underlie a strict standard of quality. Additional to UPVC pipes, extruded UPVC plain fittings and UPVC threaded fittings, we also offer the different accoutrements needed for pipe installations. Silicon-free produced products, flanges and seals, as well as fixing material round off our selection of products. The following details were gathered with best knowledge and care. Nonetheless itís not possible to trace back a reliability from the given information. UPVC is a chlorinated, amorphous thermoplastic. The Akatherm FIP products are made of hard PVC (without plasticizers). Products made out of this material play an important role in the industrial building of conduits because of their material specific features. Material property The following material data are guidelines, which might differ depending on the chosen treatment. Therefore they canít be taken over for the finished product. For further information on all Kwerk GmbH products and services contact our Customer Services Department as detailed below. Customer Services Tel: 0049 2602 999730 Fax: 0049 2602 9907329 Email: info@kwerk.de |

|

Material-Properties- The UPVC is basically inert to most inorganic bases, acids, saline solutions and paraffinical/aliphatic hydrocarbons. It is not recommended for use with polar organic solvent, including chlorinated and aromatic types. - The unique molecular structure grants a low coefficient of ther-mal conductivity (λ= 0,15 W/m °C according to ASTM C177). It virtually eliminates condensation and offers superior heat retention reducing heat loss through piping walls. - Low permeability to oxygen and reduced water absorption (0,1% at 23°C according toASTM D 570). - Good resistance to ageing, thanks to the chemical and physical properties of the UPVC resin. - All components are suitable for conveying potable water, beverages and food. The basic resins employed are all NSF approved. |

|

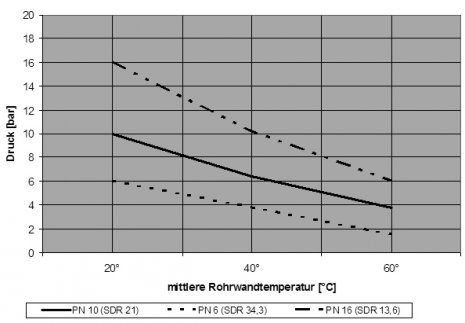

Pressure-Temperature-graphThe graph is based on a surrounding temperature of 20°C and water as a medium. The pressures in the chart are valid for a life span of 25 years and an included safety margin of 2.5. |

|

Concerning the admissible working pressure for fixing material made out of UPVC we refer to the PN-data for the accoutrements (20°C and Water). For different temperatures or mediums please make reference to our product management.

Advantages of the UPVC-SystemThe material UPVC is characterized by its hardness, dimensional stability and exceptional chemical resistance which result from the interaction of the chlorine atoms in the polymer chain. These characteristics predestine the material UPVC to be used in the production of pipe installations under pressure. Behaviour of UPVC when used outsideUPVC is weather resistant in middle European climate zones north of the Alps even under the influence of the short wave UV-parts of the sunlight. Nonetheless UPVC loses a little bit of its impact-resistance and therefore it is to your advantage to protect the material by using an Isolation system, a cover or a protective coating in case the product is used under extreme conditions. Chemical resistanceUPVC has an exceptional chemical resistance, even under the influence of high temperatures or medium concentrations. In comparison to a multitude of dilute or concentrated acids and bases , alkalis and aliphatic compounds, UPVC is rated as resistant. It shows weaknesses when confronted with mediums like ester, ketone, chlorinated hydrocarbons and several other solvents. UPVC is not resistant towards strong oxidants. The chemical resistance depends on multiple factors, for example the operating temperature, the operating pressure, the concentration and other influences. If you have a special request you can look up the resistance in our resistance list or contact our product management. Temperature- and pressure range of applicationUPVC is usable in a temperature range from 0°C up to 60°C. Temperatures higher than 60°C soften the material relatively fast. Under 0°C the impact-resistance decreases, therefore Akatherm FIP doesnít recommend the use of UPVC in this range of temperature. Concerning the internal pressure capacity of tubes and patterns we refer to the graph under the section Pressure-Temperature-graph. For details regarding the maximum internal pressure capacity of accoutrements please note the additional comments regarding the accoutrement or make reference to our product management. Electrical propertyUPVC is a polar, amorphous thermoplastic with exceptional insulation properties. Because of the possibly resulting static electricity UPVC canít be used in situations where a danger of inflammation or explosion exists. Low weightUPVC systems weigh only half in comparison to copper pipe installations and only 1/5 compared to steel pipe installations. This simplifies the handling and new fields of application are possible, in which UPVC can replace metallic systems because of its special characteristics. As all thermoplastic plastics UPVC has a relatively high thermic coefficient of expansion (0,08 mm/m °C). This fact has to be taken into consideration during the planning of the tube system. There exist several possibilities: Installation of an expansion arc or compensators as well as clamping them at fixed points. In order to do this, sound knowledge of the use of plastic is necessary and we recommend to calculate the planned system with the help of a computer program. Easy connectionUPVC tube components are connected to each other with adherence. The production of such glued joints requires expertise, which can be acquired in classes held by Akatherm FIP. Concerning the adherence please take into consideration the special guidelines from the adhesive supplier or the published instructions from the KRV (Kunststoffrohrverband e.V.) as well as the corresponding DVS-explanatory leaflets. Pipe clamp distancesPipe clamp distances for tubes made of UPVC (PN 10) in a medium with a density <1 g/cm³ |

|

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|