PVC-U transparent Sediment strainer with BSP threaded female union ends, EPDM

delivery time: 2-3 days

|

|||||||||||||||||||||||||||||||||

|

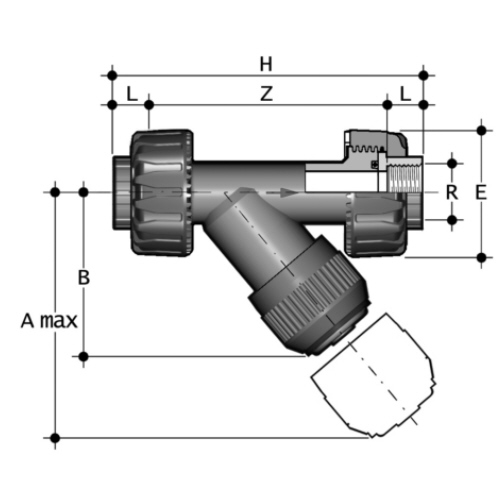

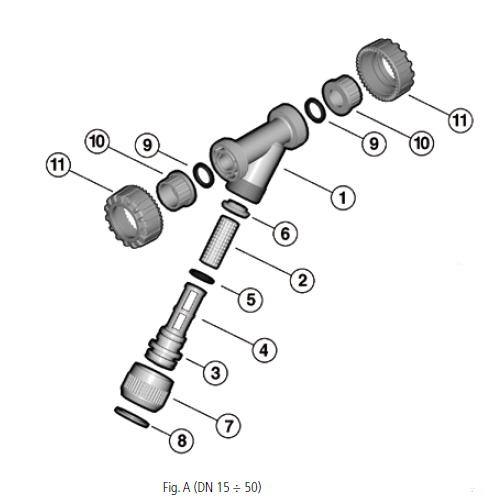

- Connection system for solvent weld, threaded and flanged joints - Strainer mounted on an easily removed support that facilitates the cleaning or replacement - Valve material compatibility (PVC-U) with water conveyance, drinking water and other food substances according to current regulations - Can be maintained with the valve body installed Construction Sediment strainer - Size range DN 10÷100 - Nominal pressure - PVC-U Grey DN 10÷50:PN 16 with water at 20 °C DN 65: PN 10 with water at 20 °C DN 80÷100: PN 6 with water at 20 °C PVC-U Transparent DN 10÷25: PN 16 with water at 20 °C DN 32÷50: PN 10 with water at 20 °C DN 65: PN 6 with water at 20 °C DN 80÷100: PN 4 with water at 20 °C - Temperature range 0 °C ÷ 60 °C Coupling standards - Solvent welding: EN ISO 1452, EN ISO 15493, BS 43461, DIN 8063, NF T54-028, ASTM D 2467, JIS K 6743. Can be coupled to pipes according to EN ISO 1452, EN ISO 15493, DIN 8062, NF T54-016, ASTM D 1785, JIS K 6741 - Thread: UNI ISO 228-1, DIN 2999, ASTM D 2467, JIS B 0203 - Flanging system:: ISO 7005-1, EN ISO 1452, EN ISO 15493, EN 558-1 (DN 10÷50), DIN 2501, ANSI B.16.5 cl.150, JIS B 2220 - Reference standards Construction criteria: EN ISO 1452, EN ISO 15493, - Test methods and requirements: ISO 9393 - Installation criteria: DVS 2204, DVS 2221, UNI 11242 Valve material Body: PVC-U grey or transparent Strainer: PVC-U or STAINLESS steel Seal material EPDM or FPM |

|

||||||||||||||||||||||||||||||||

Information:

Information:

Information:

Information:

Information:

Information:

Information:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FIP PVC U Strainers - Cleaning Power for Your Pipeline Systems. Trust in the longstanding partnership with Kwerk GmbH |

|

The FIP Italy PVC U strainers are high-quality valves specifically designed for use in pipeline systems. They are used to effectively trap impurities and solids from the flowing media, protecting pumps, valves, and other components from damage and clogging. FIP Italy offers a variety of PVC U strainers in different configurations to meet the specific requirements of applications. These include flanged strainers, equipped with flanges for easy installation and removal, as well as threaded fitting strainers, providing a secure and reliable connection in threaded joints. These configurations are suitable for applications with both larger and smaller diameters. The PVC U strainers from FIP Italy are available with various perforations to meet the specific needs of the application. They can be equipped with holes or slots in the filter drum, depending on the type of impurities in the medium and the desired filtration level. The FIP Italy strainers are made of high-quality PVC U material, which exhibits excellent resistance to chemicals, corrosion, and mechanical stress. PVC U is a robust and durable material that ensures reliable performance even under demanding environmental conditions. Kwerk GmbH is a longstanding distributor partner of FIP Italy, providing access to a wide range of PVC U strainers. As a renowned B2B portal for valves and fittings, Kwerk GmbH is committed to delivering top-quality products and services. Our dedicated team of experts will assist you in selecting the right PVC U strainers for your specific requirements. Trust in the high-quality PVC U strainers from FIP Italy available through Kwerk GmbH. Our products are manufactured according to international standards and provide reliable performance for your pipeline systems. Enhance the efficiency and reliability of your facilities by effectively filtering impurities and protecting sensitive components. Rely on the longstanding experience and expertise of Kwerk GmbH to find the right solution for your needs. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|