PVC-C Butterfly Valve, hand operated, FPM

delivery time: 3-4 days

|

|||||||||||||||||||||||||||||||||

|

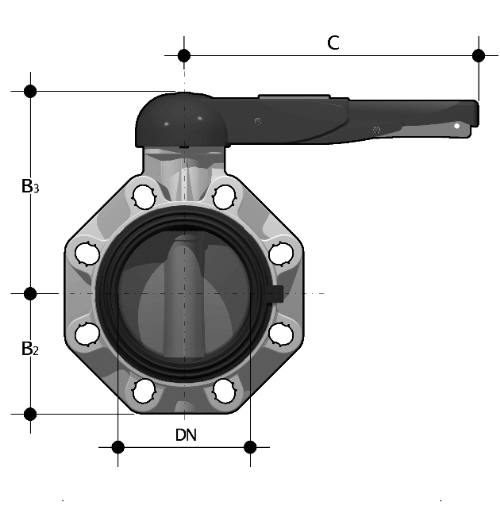

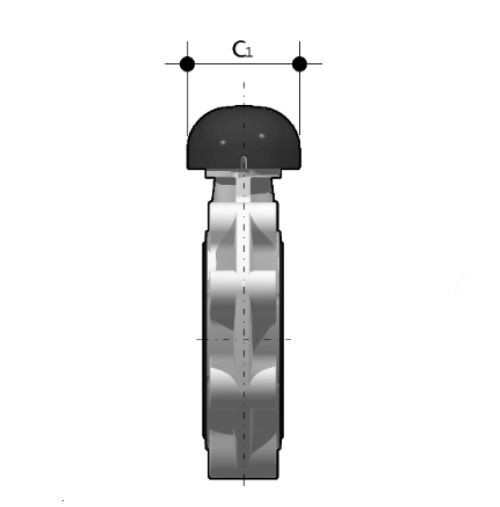

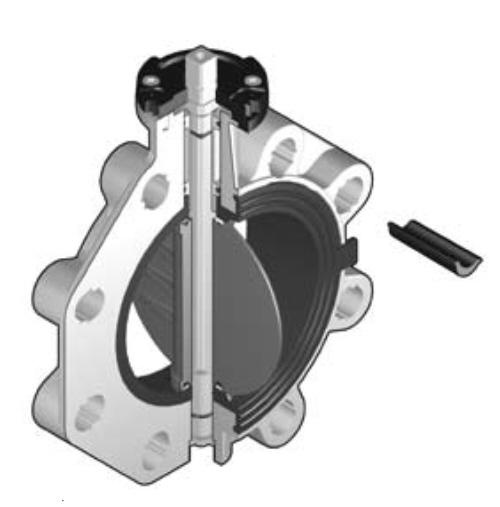

- Interchangeable Disk in PVC-C with through shaft, available in different thermoplastic materials: PP-H, PVC-U, ABS, PVDF - Overall dimensions of the valve in accordance with standard ISO 5752 (DN 40÷200 Medium Series 25, DN 250÷ 300 Long Series 16) and DIN 3202 K2 and ISO 5752 (DN 65÷200 K2, DN 250÷300 K3) - Can also be installed as an end line valve, bottom discharge valve or tank dump valve - Special Lug version PN 10 fully drilled to DIN 2501 or ANSI B16.5 cl.150 with molded-in AISI 316 stainless steel threaded inserts - Valve material compatibility (PVC-U) with water conveyance, drinking water and other food substances according to current regulations - Possibility of installing a manual reducer or pneumatic and/or electric actuators by applying an ISO standard drilling PP-GR flanges. DN 40÷200 valve fitted with plate with rack in PP-GR. For actuated versions with flange drilled according to ISO 5211 F05, F07, F10. DN 250÷300 valve, fitted with one-piece top flange in high mechanical strength PP-GR with mounting flange for internal components drilled according to standard ISO 5211 F10, F12, F14 MAIN FEATURES: - Ergonomic handle in HIPVC equipped with locking and unlocking device, release, quick operation and graduated adjustment in 10 intermediate positions (DN 40÷200). The operating range, starting from the first few degrees of valve opening, also guarantees extremely low pressure drops - Customisable Labelling System: integrated module in the handle, made of a transparent protection plug customisable tag holder using the LSE set (available as accessory). The customisation lets you identify the valve on the system according to the specific needs - Stainless steel AISI 316 square section stem completely isolated form the fluid complying with standard ISO 5211: DN 40÷65: 11 mm DN 80÷100: 14 mm DN 125÷150: 17 mm DN 200: 22 mm DN 250÷300: 27 mm - Body in polypropylene based compound reinforced with fibreglass (PP-GR) resistant to UV rays and characterised by high mechanical strength - Drilling pattern using oval slots that allow coupling to flanges according to numerous international standards. The special self-centring inserts in ABS supplied for DN 40÷200 guarantee the correct axial alignment of the valve during installation. For DN 250÷300 valves, the drilling pattern for the selfcentring system is of the traditional type according to DIN and ANSI standards - Interchangeable liner with the dual function of forming a hydraulic seal and isolating the body from the fluid |

|

||||||||||||||||||||||||||||||||

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precise control and reliable performance - CPVC valves for your pipeline systems |

|

CPVC valves are a versatile solution for precise control of media flow in pipeline systems. They are known for their exceptional chemical resistance and mechanical strength, making them ideal for demanding industrial applications. The following are some key CPVC valves that will help you operate your pipeline systems efficiently and reliably: CPVC 2/2-way ball valve: The CPVC 2/2-way ball valve allows precise control of media flow by simply rotating a ball with a through hole. This versatile ball valve is ideal for applications that require quick opening or closing of the media flow. CPVC 3-way ball valve with L-port: The CPVC 3-way ball valve with L-port offers the ability to divert media flow in three different directions. This valve allows for complex flow control and is particularly useful in applications where different flow patterns are required. CPVC 3-way ball valve with T-port: The CPVC 3-way ball valve with T-port enables efficient distribution of media flow in three different directions. This valve provides reliable control and is ideal for complex systems where multiple pipelines need to be merged or split. CPVC diaphragm valve Type 286: The CPVC diaphragm valve Type 286 is known for its high sealing integrity and reliable sealing. It is particularly suitable for applications that require precise regulation of media flow. The valve is controlled by raising and lowering a diaphragm, ensuring reliable and controlled flow regulation. CPVC diaphragm valve Type 882: The CPVC diaphragm valve Type 882 offers excellent chemical resistance and is ideal for use in aggressive environments. With its precise flow control and easy handling, it is a popular choice for demanding industrial applications. CPVC butterfly valve: The CPVC butterfly valve is a robust and durable valve that allows for effective isolation of media flow. It is ideal for applications that require quick and reliable shut-off. CPVC end cap valve: The CPVC end cap valve is a special type of valve that is installed at the end of a pipeline. It provides a simple and efficient way to control and isolate media flow. CPVC strainer: The CPVC strainer ensures effective filtration of solid particles and debris in the pipeline. It protects sensitive components from clogging and allows for smooth media flow. These CPVC valves are available in various sizes, types, and standards to meet the different requirements of your application. They ensure reliable and precise control of media flow and contribute to the efficient and safe operation of your pipeline systems. As a leading manufacturer of CPVC valves, our partner, Kwerk GmbH, offers high-quality products and solutions for your demanding requirements. Trust in the outstanding quality and performance of our CPVC valves and optimize your industrial processes. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|