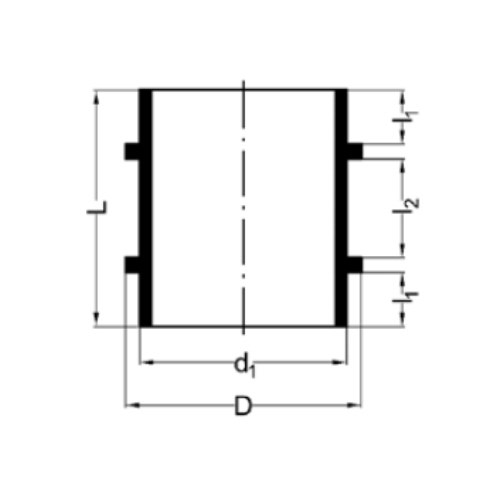

PE Double-flange bushing, for soil & waste systems

delivery time: 2-3 days

|

| Quality and certification Akatherm HDPE is developed and manufactured within an ISO 9001 Quality Assurance system and complies with the EN 1519 and other relevant international standards as well as meeting numerous national approved quality and safety standards. Jointing technology Akatherm HDPE offers a choice of welded and mechanical jointing techniques. Welded joints provide a homogenous joint ideal for ceiling voids, vertical stacks and underground pipework. Mechanical joints offer adjustability, flexibility and the option to demount. |

|

|

||||||||||||||||||||||||||||||

Information:

Information:

Information:

Information:

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PE Drainage Pipes - Quality, Reliability, and Efficiency for Your Drainage Solutions |

|

Our product range includes PE drainage pipes manufactured according to DIN EN 1519. Since January 2001, this European product standard has replaced the national standard DIN 19535 for pipes and fittings used for conveying wastewater within building structures. Additionally, the national application standard DIN 1986 has been replaced by the European standard DIN EN 12056, with any missing regulations addressed in the national supplementary standard DIN 1986-100. According to DIN EN 12056, the DN designation of drainage pipes is based on the actual internal diameter specified by the manufacturer. The nominal size, which always corresponds to the largest outer diameter, is no longer the determining factor. These hydraulic values are based on the specified internal diameter according to DIN EN 12056. It should be noted that the DIN EN 12056 standard applies exclusively to gravity-operated drainage systems within building structures. Drainage pipes outside the building up to the property boundary are subject to the standards DIN EN 752 and DIN EN 1610, as well as the ATV guidelines A127, A139, and A142, if applicable. Our PE drainage pipe product range includes the following DN/OD sizes in mm, de (outer diameter), and e (wall thickness) for the S16 series:- DN/OD 40: de 40 mm, e 3.0 mm, application range BD - DN/OD 50: de 50 mm, e 3.0 mm, application range BD - DN/OD 56: de 56 mm, e 3.0 mm, application range BD - DN/OD 63: de 63 mm, e 3.0 mm, application range BD - DN/OD 75: de 75 mm, e 3.0 mm, application range BD - DN/OD 90: de 90 mm, e 3.5 mm, application range BD - DN/OD 110: de 110 mm, e 4.2 mm, application range BD - DN/OD 125: de 125 mm, e 4.8 mm, application range BD - DN/OD 160: de 160 mm, e 6.2 mm, application range BD - DN/OD 200: de 200 mm, e 6.2 mm, application range B (S16) - DN/OD 250: de 250 mm, e 7.7 mm, application range B (S16) - DN/OD 315: de 315 mm, e 9.7 mm, application range B (S16) The mentioned material properties serve as guidelines and may vary depending on the processing method. Therefore, they cannot be directly applied to finished parts. Here are some important material properties of PE drainage pipes:- Density: 0.954 g/cm³ - Tensile stress at 23°C: 22 MPa - Tensile modulus at 23°C: 850 MPa - Linear expansion: 0.13-0.19 mm/m°C - Charpy impact strength at 23°C: 12 kJ/mm² Thermal conductivity: 0.38-0.43 W/m°C Elongation at break: 300% MFR 190/5: 0.43 g/10min Please note that these values are general guidelines and may vary depending on the specific properties of the PE drainage pipes used. For specific applications, we recommend considering the manufacturer’s technical data and, if necessary, obtaining further information. Our team, with years of experience in the field of PE drainage pipes, is available to answer your questions and assist you in selecting the right product. Feel free to contact us at +49 2602 999730. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|