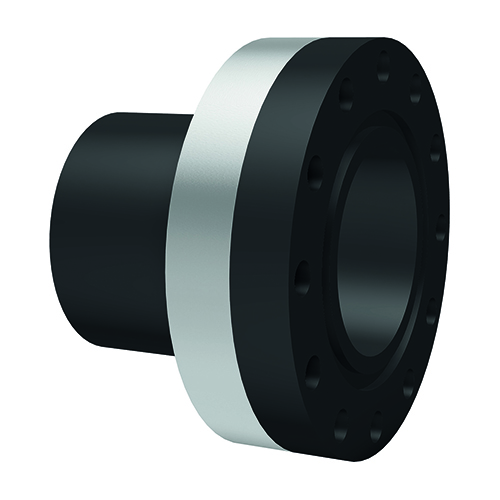

PE100 Special flange connection, long, SDR17, PN10

delivery time: 2-3 days

|

||||||||||||||||||||

|

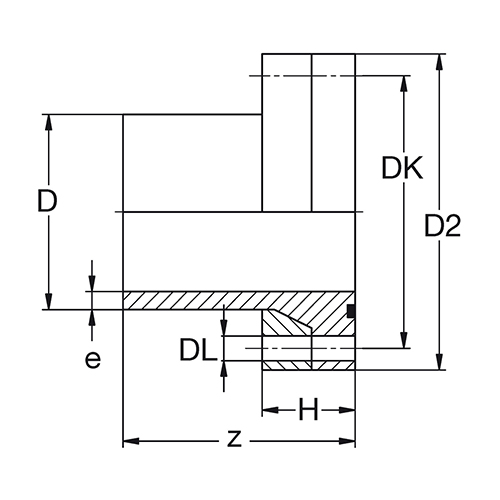

PE100 Sonder-Flanschverbindung lang Ausführung Langes Schweißende; für Heizelement-Stumpf-Schweißen und Heizwendel-Muffen-Schweißen geeignet. Gebohrt nach DIN EN 1092-1. Standardmäßig mit Runddichtring- EPDM. SDR11/17 und PN10/16. Mit kunststoffbeschichtetem Sphäroguss- oder Stahlflansch. Ausführung abhängig von der SDR-Klasse und DN/D-Kombination. Optional Flansche aus Edelstahl; Flansche aus verzinktem Stahl; flachdichtend ohne Nut und ohne O-Ring; PN25 gebohrt; mit Langloch. Für Gasleitungen mit glatter Dichtfläche oder NBR-Dichtung lieferbar. Anwendung Direkter Anschluss an Armaturen ohne Reduzierung der Nennweite (DN). Besonderheiten - Besonders stabil - Strömungsgünstig - Reduzierter Totraum - Integrierte O-Ring-Dichtung - Klappe der Armatur ist frei beweglich |

|

|||||||||||||||||||

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Strong Connections for a Secure Future: Our PE Fittings for Reliable Welding Solutions |

|

PE fittings with long-welding SDR 11/17 in black - Perfect solutions for butt fusion welding and socket fusion welding with heating coil. Are you in search of high-quality PE fittings for your heating or pipeline systems? Our injection-molded PE fittings are the ideal choice. They stand out with outstanding physical and mechanical properties that give them versatile applications. Thanks to their fine surface structure, our PE fittings are perfect for the transportation of gases and liquids. Additionally, they offer excellent UV resistance, allowing for outdoor installations without the need for additional protective measures. For many decades, our fittings have proven their worth in gas and water supply, impressing with their durability and reliability. Our PE fittings are made of high-quality polyethylene (PE100), classified according to the Minimum Required Strength (MRS). Kept in black, our fittings meet the requirements of the current KTW guidelines of the Federal Environment Agency (UBA). They comply with the EN 1555 standards for gas supply and EN 12201 for drinking water supply, ensuring you can rely on their quality and safety. The PE fittings possess a range of impressive properties. They are lightweight, chemically resistant, and exhibit high impact strength even at low temperatures. Additionally, they are corrosion-resistant and demonstrate excellent resistance to light, weathering, and abrasion. These properties make them a reliable choice for various applications. The geometric properties of our PE fittings comply with the EN 1555 and EN 12201 standards regarding the outer diameter and wall thickness. Tolerances for the Z-dimensions vary depending on the dimension. For a diameter smaller than or equal to 160 mm, the tolerance is +/- 3 mm, while for a diameter of 180 mm and above, it is +/- 10 mm. The PE fittings can be used for both butt fusion welding and socket fusion welding according to the DVS guideline 2207. To ensure a safe and reliable welding connection, we recommend using welding devices and tools that comply with the DVS guideline 2208. Our partner Bänninger is a reputable company with years of experience and expertise in materials, manufacturing, quality, application, support, and logistics. Through this strong partnership, we can offer you a comprehensive range of high-quality products and excellent services. Trust in our expertise and contact us today to find the perfect solution for your pipeline systems together. With our PE fittings and the support of Bänninger, you are well-equipped for efficient and reliable installations. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|