Seamless bend 30°, SDR17, PE 100-RC, long spigot for butt- and electrofusion welding

delivery time: 2-3 days

|

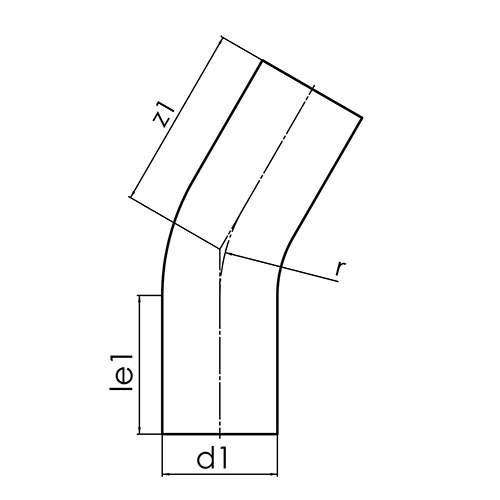

| Seamless bends r ? 1,5 x d - Material: PE 100 RC - long spigot for butt- and electrofusion welding - other dimensions, materials and pressure classes on request - tolerance ± 5° |

|

|

||||||||||||||||||||||||||||||

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The first and only DVGW-certified seamless bend pipeline construction at the highest level |

|

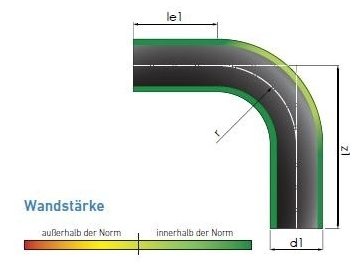

After years of research, we are the first and only manufacturer capable of producing compliant DVGW-certified seamless bends with "r ≈ 1.5 x d", which meet the required minimum wall thickness according to DIN EN 12201-3 and DIN EN 1555-3, thus providing optimal conditions even for the highest stress. Products with the DVGW mark provide assurance that they are high-quality products that fully comply with recognized rules and the current state of the art. Our unique DVGW-certified seamless bend sets itself apart from other seamless bends and is proven to have remarkable durability and high reliability. By adhering to the minimum wall thickness, norm-compliant DVGW-certified seamless bends from STAR offer the highest level of safety and enable pipeline construction at the highest level according to standards. |

|

|

The standards DIN EN 12201-3 and DIN EN 1555-3 regulate quality standards for PE plastic pipe systems used in gas and water supply, as well as drainage and pressure sewage pipelines. These standards prescribe dimensions, welding lengths, tolerances, and material properties. They also include requirements for the wall thickness of seamless bends. The suffix "-3" indicates that the standards apply not only to the pipe itself but also to the finished fittings. In summary, these standards establish guidelines for the construction and installation of PE pipe systems, ensuring that they meet the required quality standards and provide safe and reliable performance. Compliance with these standards allows manufacturers and installers to demonstrate that their products adhere to recognized rules and the current state of the art. |

|

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|