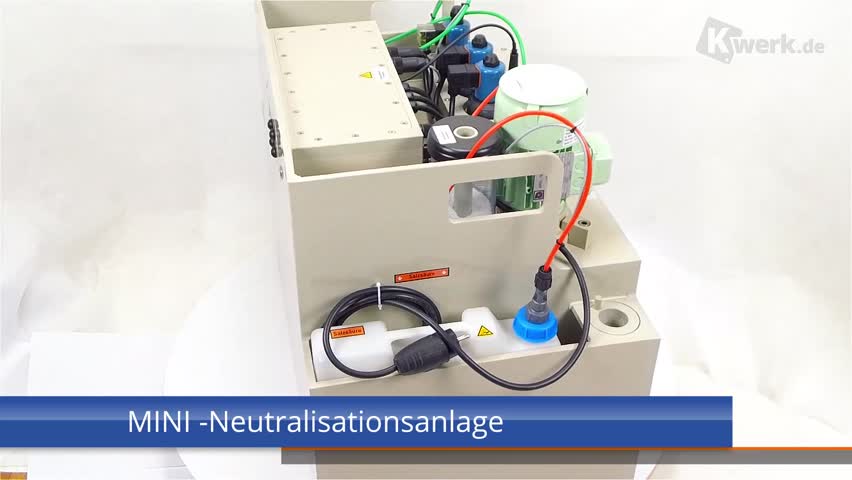

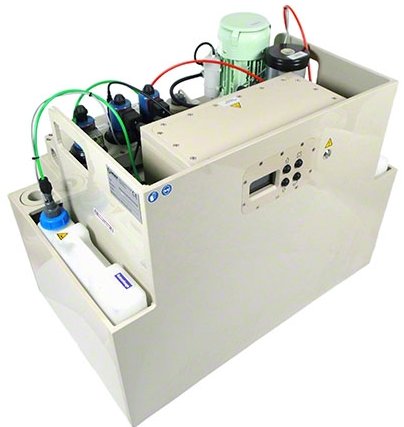

NEUTRALISATION PLANT - MINI - 400L/HUSER-FRIENDLY PLANT FOR INDUSTRY AND LABORATORY |

|

HIGH-QUALITY, COMPACT AND LOW-NOISEThe advantages of the mini-plant at a glance:• Neutralisation performance up to 400 liters per hour • Low weight and fully-automatic in and out flow • Due to the small outside dimensions ideally suitable for applications in the industrial sector, under laboratory benches and washbassins • Low-cost, but nevertheless solid industrial design with high-quality components • Extremely silent by means of dry-run safe pump and dosing by magnetic valve • Highest operating comfort and plant safety by micro process control, including pH control • Dialogue-guided menu control • Easy change and calibration of the pH elektrode |

Short process descriptionWastewater in the range of pH 2 and pH 12 gets to the plant via a free inlet. After having reached the maximum filling level, the fully automatic neutralisation process will be started. The integrated agitator mixes permanently the incoming wastewater and the unit records the pH value. Depending on the pH value, acid or alkali are proportionally added. As soon as the wastewater is neutralised, it will be discharged fully automatically into the pipe system, which must be provided at the customer site. Should you have any further questions relating to this product, just call us or send us an inquiry. |

|

Technical data- Length 780 mm, width 480 mm and height 600 mm - Material PP - Empty weight approx. 50 kg - Capacity 75 l - Wastewater temperature 40 °C max. - Neutralization quantity max. 300 up to 400 l/h (depending on wastewater hardness) - Setting range pH 2 to pH 12 - Dosing tanks, each approx. 5 l acids/alkalis - Discharge fully automatically (no operator needed) - Two-colour display, red/green for operating and malfunction message - Feed nozzle DN 25 or KG D40 D50 - Overflow nozzle DN 32 - Outlet nozzle DN 25 or according to customer request - Spare nozzle DN 40 (option) - Acid vapor separator with granulate |

|

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|