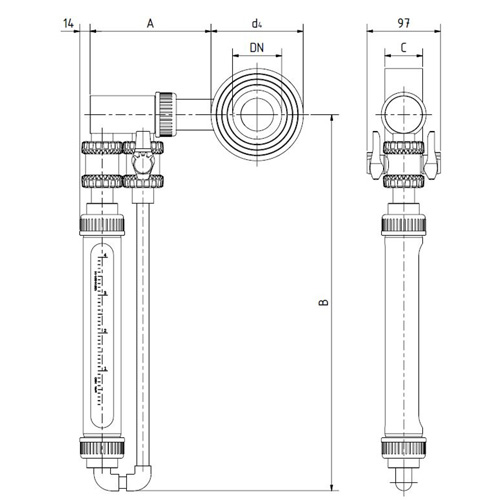

Stainless steel Bypass flow meter type DST-V4A PN 10 DN 200

Availability: 4-5 working days

|

| Pipe inside diameter: Please specify when ordering. Flow direction: Please specify when ordering. (left to right, right to left, bottom to top, top to bottom) Overall length: 50 mm pmax:10 bar at 20° C Plexiglas protection Ring: 1.4571 Orifice: 1.4571 Standard float: 1.4571 Standard seals: FKM Corrosion protection: Epoxy resin powder coating, traffic blue (RAL 5017) glossy Corrosion category: C3 In accordance with the PED, the appliance is designed for use in Category 2 and can also be used in category 1 and Art. 4.3. |

|

|

||||||||||||||||||||||||||||||

Information:

Information:

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BYPASS FLOW METERS |

|

The extensive range of materials available for our DST bypass flow meters enables the flow measurement of a wide variety of media. The cost-effective device in PVC is often used in bathing water technology. The device in PVDF is ideal for measuring the flow of aggressive media, e.g. in water treatment, while the DST-1/2 in steel is mainly used for measuring air and gases. The measuring range for H2O extends from 0.02-0.16 to 300-1800 m3/h, for air from 0.15-1.5 to 1200-6000 m3/h i.N. The DST bypass flow meter works according to the differential pressure method. A ring with an orifice plate is installed in the pipe. The orifice plate leads to a constriction and causes a pressure drop. This pressure drop is quadratically proportional to the flow rate. If the pressure tapping points upstream and downstream of the orifice plate are connected to a pipe, a bypass flow flows in this pipe. This bypass flow is a measure of the flow rate of the flow in the main line. Two ball shut-off valves integrated into the secondary line make it possible to switch the secondary flow on or off as required. The devices can also be used as monitors by installing electrical limit switches that can be adjusted over the entire measuring range. |

|

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|