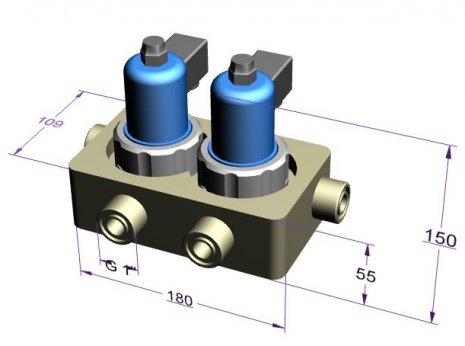

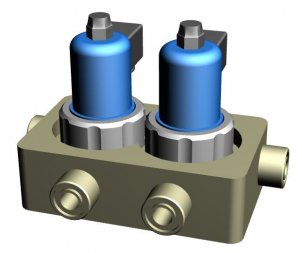

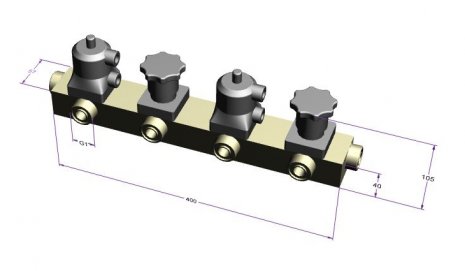

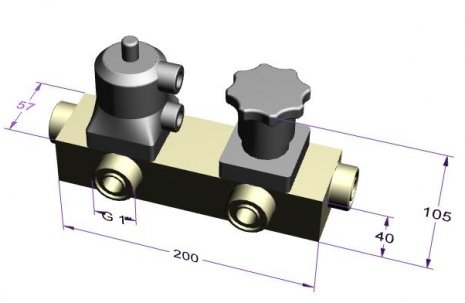

MAGNETIC VALVES – BLOCK CONSTRUCTION –SERIES KW BL-MA-15Plastic block valves find use in plant and apparatus construction, when the installation space is limited. KWERK.DE develops block valves as magnetic valve and as diaphragm valve made of PVCU, PVCC, PE, PP, PVDF, PTFE, as well as of special materials. Multi-port valves are used for discharge, sampling, distribution and mixing of different media. Due to the new technical possibillities like CAD and CNC, customized solutions can be realized even in small quantities. The advantages of a multi-port valve are obvious: positioning of connections and, where appropriate, integration of measuring points. Benefit from the KWERK KNOW HOW for improvement of the plant technology and optimization of the process technology. Multi-port valves provide special advantages for users:- Cost saving (less fittings and piping material) - Less bonds and weldings - Minimized dead areas - Narrow installation space to be realized - Complex circuits in the process technology available - Directly controlled all-plastic valve with high switching speeds - Core tube sealed by PTFE bag bellow, independent of compressed air supply - ATEX and manual override available A PP multi-port valve with two magnetic valve drives of type 150 is shown opposite: - Nominal size DN 20, DN 10, DN 15 available on request - With two magnetic valves of type 150 in the two valve combination - Pass S1 to S2, medium e.g. as ring line, permantly pending, from the volume flow S1/S2 the connections S3 and S4 can be fed with medium by switching the drives - Connection: G1 inch with O-ring groove, fitting to the common screw joints with bonding or welding inserts - This distributor can be extended to 3, 4, 5 valve combinations or more - Integration of measuring points for PH, REDOX and temperature are available - Nominal pressure according to layout The magnetic valves are availabe with the switching functions NC and NO, further in the versions 24V AC/DC, 230V AC, 12 V AC/DC and 110 V AC/DC. Seal optionally in EPDM or FPM. On request, we will be pleased to send you our detailed quotation, if desired, also for other variants. Multi-port valve with magnetic valves: |

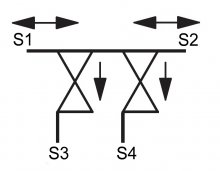

R & I SymbolInstallation position: horizontally and vertically, e.g. in a ring line - S1 and S2 pass - S3 and S4 discharge  |

|

|

|

|

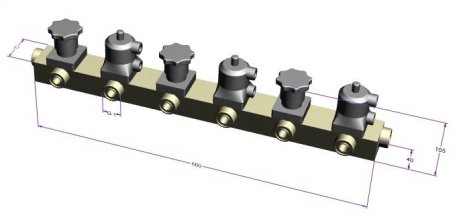

DIAPHRAGM VALVES IN BLOCK CONSTRUCTIONSERIES KW BL-ME-15In our ultra-modern manufacturing plant, we produce customized multi-port valves with diaphragm valves in block construction. The drives are availble as pneumatic version in NC and NO and are compatible with manual drives. You as user, will benefit from many advantages and enormous cost savings. The shown "distributors" are examples for various possibilities and will be manufactured custom-designed in PVCU, PVCC, PE, PP, PVDF and other special materials. Pneumatic drives feature the following: - 2/2-way diaphragm valve with pneumatic actuator and optical position indication - Function: normally closed NC or optionally NO - Membrane material: optionally EPDM - FPM - PTFE/EPDM - Control pressure: 4 - 7 bar - Control connection: R 1/4’ - Control connection in flow direction: upon request - Drive colour: black Manual drives: - Membrane: optionally EPDM - FPM - PTFE/EPDM - including adjustable closing limit - Operating pressure: PN 6 Our technicians are looking forward to assist you with support and advice in the engineering phase and during application. On request, we will be pleased to send you our detailed quotation, if desired, also for other variants. Block valves variants - different materials: |

|

|

|

|

|

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|