CO2 - ABSORBERS FOR TANKSSeries KW – CO 2 - 160/250/315 |

Technical Notes on CO 2 - ABSORBERThe CO 2 absorber is used to separate carbon dioxide-containing exhaust air when filling or emptying containers. It is designed for use in medical technology and clean room applications. The filtering effect is based on absorption, adsorption and chemical reaction. Gases come into contact with the filter media and are neutralized by oxidation into mineral residues. Desorption is no longer possible. Regular media analyzes enable a precise change forecast for seamless service and availability assurance. In addition to the absorber granulate, a 10-inch sterile filter cartridge is installed in the CO 2 absorber. Please note: The max. Loading is and the consumption of the granules is process-dependent and if necessary to clarify technically. Accessories and spare parts- Screw parts for butt and socket welding for screw connections in available in the following materials: PP, PE, PVC, PVDF, PE-EL, stainless steel - PE cover - Inlay part / stub end PP, PE, PVC - Loose flange made of PVC or PP - Steel - PVC housing - transparent - EPDM / PTFE / FPM seals - Absorber granulate - Sterile filter 10 Inch Missing dimensions and other dimensions and materials on request. . |

|

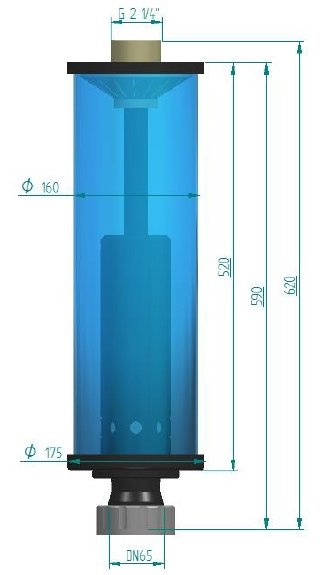

Technical Data CO2 Absorber Typ 160 |

|

Series 160- CO 2 absorbers for use in medical technology and clean room applications - Carbon dioxide is reliably absorbed by the granules - Insulating or changing the absorbent granules by unscrewable lid - Saturation of the granules visible by color change - CO 2 Absorber 160 optionally available with union nut DN 65 or loose flange DN 65 - Sterile filter cartridge for smallest (micro) solids optionally available filter insert - 1 piece of sterile filter 10 inches, fineness 0.2 microns  Fill - Recommended filling quantity for granules is 5 liters  |

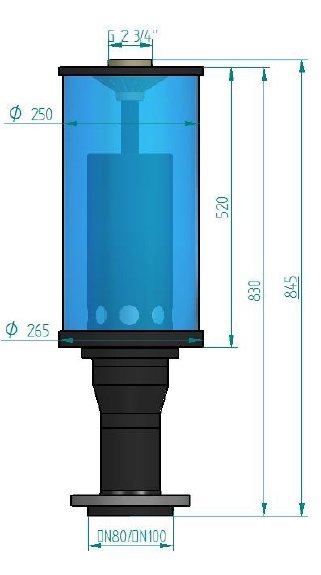

Technical Data CO2 Absorber Typ 250 |

|

Series 250- CO 2 absorbers for use in medical technology and clean room applications - Carbon dioxide is reliably absorbed by the granules - Insulating or changing the absorbent granules by unscrewable lid - Saturation of the granules visible by color change - CO 2Absorber 250 optionally available with loose flange DN 80 or loose flange DN 100 available - Sterile filter cartridge for smallest (micro) solids optionally available filter insert - 2 piece of sterile filter 10 inches, fineness 0.2 microns  Fill - Recommended filling quantity for granules is 10 liters  |

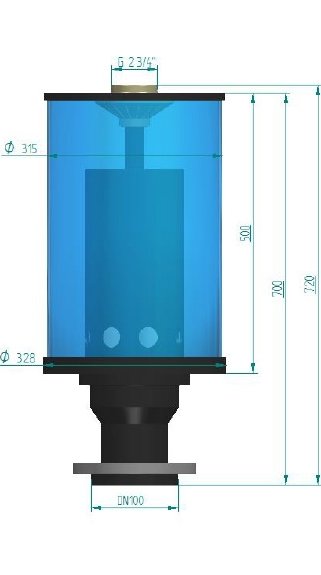

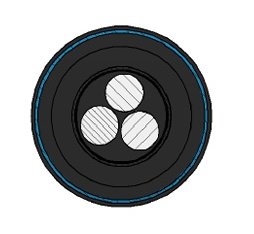

Technical Data CO2 Absorber Typ 315 |

|

Series 315- CO 2 absorbers for use in medical technology and clean room applications - Carbon dioxide is reliably absorbed by the granules - Insulating or changing the absorbent granules by unscrewable lid - Saturation of the granules visible by color change - CO 2 Absorber 315 optionally available with loose flange DN 100 - Sterile filter cartridge for smallest (micro) solids optionally available filter insert - 3 piece of sterile filter 10 inches, fineness 0.2 microns  Fill - Recommended filling quantity for granules is 10 liters  |

Overview Delivery program CO 2 Absorber |

|

CO 2 absorbent granulesWith the CO 2 absorption granulate, KWERK GmbH offers a high-performance absorption medium with a consumption indicator for the absorption of carbon dioxide (CO2) in industrial applications. These include u. a. Ventilation filter for wastewater systems and cooling water (deionized), as well as protection and rescue rooms. The consumption indicator of the absorbent shows by means of discoloration from white to purple, the carbonic acid saturation and is thus the external visible signal to exchange the soda lime. The special pill shape ensures that low resistance and long operating times are offered. Only a uniform shape produces a uniform filling and thus a reproducible absorption behavior. The large internal absorption area of the pills ensures a high absorption capacity for acidic gases. At the same time, the shape ensures that the abrasion resistance is high and thus the dust nuisance remains low. Furthermore, the uniform shape allows low resistance and ensures long operating times. The uniform bed prevents the formation of channels. Typical applications: - Ventilation filter for wastewater systems - Supply air filter for cooling circuits in power plants (Deionat) - Protection and rescue rooms in mining - Rescue trains Specifications: - Grain size: 2 - 4 mm - Bulk density: 730 - 930 g / L - CO 2 absorption capacity: 23% by weight - CO 2 absorption capacity: 158 L CO 2 / kg (depending on the application parameters and the absorption system) |

General protective measures: Avoid contact with eyes and skin! Do not inhale dust! The product is not flammable! Storage: Only in cool and well-ventilated rooms in original container Keep container tightly closed! Do not store together with acids ! Storage: - 5 to 40 ° C, shelf life: 5 years - The storage temperature must not exceed 50 ° C! Hazard-determining components of labeling: calcium and sodium hydroxide - No dangerous goods ! |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|