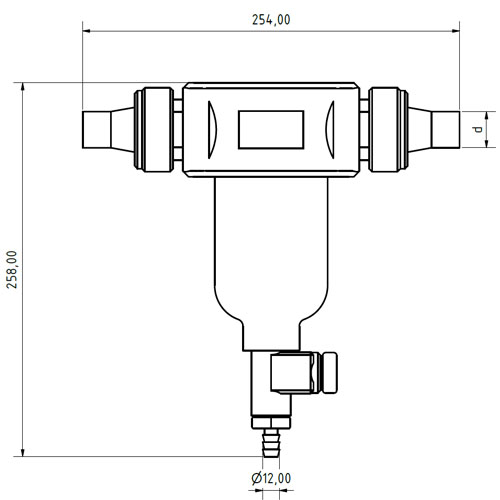

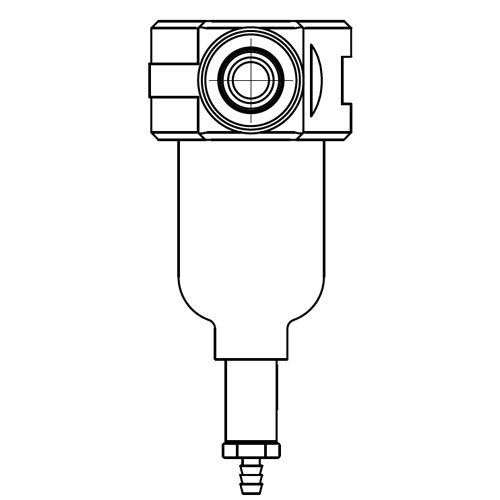

pH flow valve type UNIVERSAL d 32 mm made of PE-el, welded spigot design, EPDM seal

Delivery time: 2-3 days

|

|||||||||||||||||||||||||||||||||

|

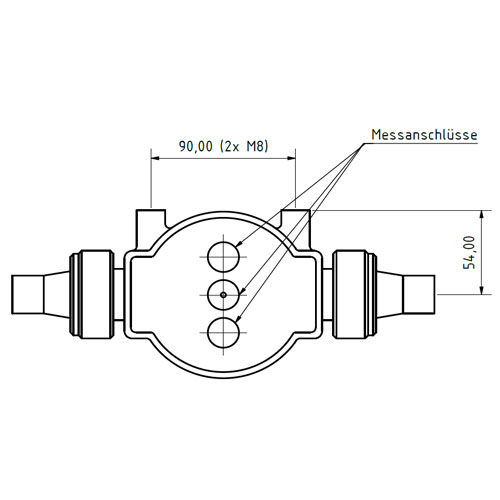

pH, temperature and conductivity measurement - High-quality fitting for measuring pH value, redox and temperature - flow direction can be changed as required by replacing the needle valve and double nipple - up to 5 electrodes with various mounting threads can be used - 3 PG 13.5 measuring connections as standard - Measuring connections can be customized, e.g. 2x PG13.5 and 1x IG 1/2", 2x PG13.5 and 1x IG 3/4", 2x PG13.5 and 1x IG 1" or only 1x IG 1 1/4", - with flow tube as standard for direct flow to the electrodes - Calibration of the electrodes possible by unscrewing the measuring vessel - with needle valve for sampling (can be rotated through 360°) - Unscrewable container - Constant medium level for keeping the electrodes moist - Pressure rating SDR11 (PN10), pressure resistance 10 bar at 20°C - Wall mounting: 2x M8 threaded bushes, stainless steel (V2A) - Electrical potential is discharged, Suitable for Ex zones 1 and 2 - Optionally with potential equalization made of stainless steel 1.4571 on request - Blanking plug PG 13.5 made of PE-el see art. No. 102132 Version: Industrial version PE-el Seals EPDM Connections: PE-el butt weld spigot DN25 / d32 SDR11 1 pc. Sampling valve PE-el |

|

||||||||||||||||||||||||||||||||

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PP-EL Electrically Conductive Plastic Valves: Safety and Performance in ATEX Environments |

|

PP-EL electrically conductive plastic valves have gained significant popularity in the chemical and process industries for their exceptional corrosion resistance, high impact strength, and suitability for ATEX environments. Designed to operate in potentially explosive atmospheres, these valves offer reliable protection against static electricity and sparks. PP-EL, a specialized polypropylene infused with carbon black, provides the required electrical conductivity to effectively dissipate static charges. This unique material composition makes PP-EL electrically conductive plastic valves ideal for ATEX applications, where safety is paramount. Selecting electrically conductive plastic valves for ATEX environments involves careful consideration of various factors. Firstly, ensuring that the valves are certified for use in such environments and compliant with relevant standards and regulations is crucial. Additionally, they must be suitable for the specific application, including the appropriate pressure rating, temperature range, and chemical resistance. Compatibility with handled fluids and the potential for static electricity build-up are also important considerations. PP-EL electrically conductive plastic valves are specifically engineered to dissipate static charges, effectively minimizing the risk of ignition in potentially explosive atmospheres. In summary, PP-EL electrically conductive plastic valves offer a safe and dependable solution for ATEX environments in the chemical and process industries. When selecting these valves, it is essential to consider the specific application requirements as well as the applicable standards and regulations for operating in potentially explosive atmospheres. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|