2-way flanged ball valve made of electrically conductive polypropylene, ANSI flanges, FEP/FFKM seal

Delivery time: 2-3 days

|

|||||||||||||||||||||||||||||||||

|

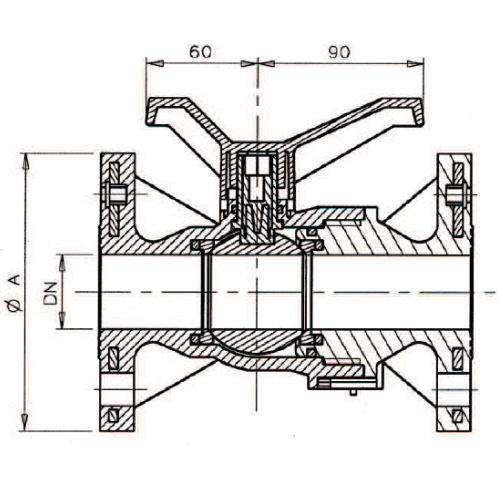

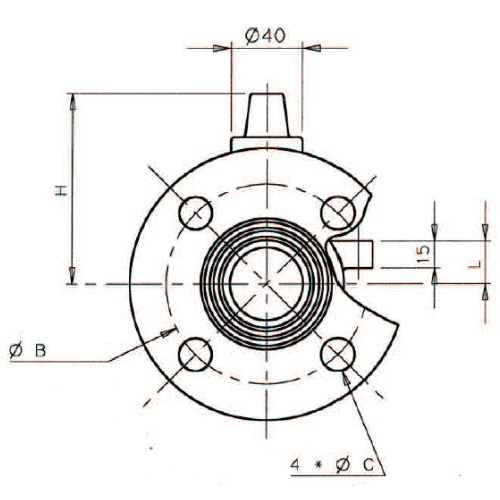

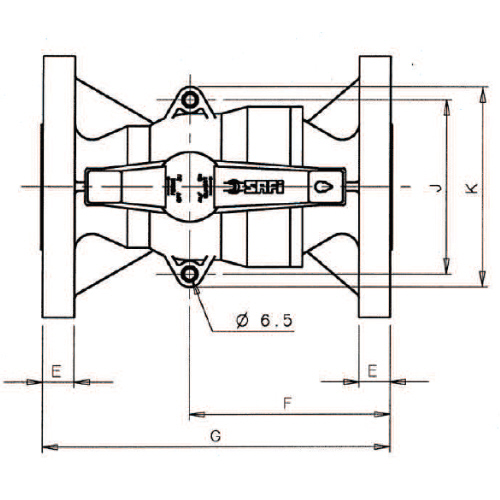

- - Flanged ball valve, 2-part, face-to-face dimension to DIN 558-1, basic series 1 - Flanges reinforced by fully encased steel insert - Flanges with sealing lips to prevent the flange flat gaskets from shifting - Non-removable locking device to prevent rotation and ensure alignment of the two connecting flanges - Flanges to DIN EN1092-1 PN10, (replaces 2501 - PN 10) - Ball valves can be easily converted to electric or pneumatic actuators by removing the hand lever - Two screw-on lugs for fastening the valves - New design ensures full passage and minimal dead space, thus limiting deposits - lever position clearly marked by appropriately shaped control shaft for replacement or removal - red safety device for ball valves with EPDM O-rings - Green safety device for ball valves with FPM O-rings - Protected lever stops - Standardized marking - Electrically conductive due to high graphite content - Atex 94/09/03 - in accordance with the Pressure Equipment Directive 97/23/CE - Operating pressure : 10 bar at 20°C - Temperature range: -5° C to +90°C - Electrical resistance less than 10 to the power of 5 Ohm |

|

||||||||||||||||||||||||||||||||

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PP-EL Electrically Conductive Plastic Valves: Safety and Performance in ATEX Environments |

|

PP-EL electrically conductive plastic valves have gained significant popularity in the chemical and process industries for their exceptional corrosion resistance, high impact strength, and suitability for ATEX environments. Designed to operate in potentially explosive atmospheres, these valves offer reliable protection against static electricity and sparks. PP-EL, a specialized polypropylene infused with carbon black, provides the required electrical conductivity to effectively dissipate static charges. This unique material composition makes PP-EL electrically conductive plastic valves ideal for ATEX applications, where safety is paramount. Selecting electrically conductive plastic valves for ATEX environments involves careful consideration of various factors. Firstly, ensuring that the valves are certified for use in such environments and compliant with relevant standards and regulations is crucial. Additionally, they must be suitable for the specific application, including the appropriate pressure rating, temperature range, and chemical resistance. Compatibility with handled fluids and the potential for static electricity build-up are also important considerations. PP-EL electrically conductive plastic valves are specifically engineered to dissipate static charges, effectively minimizing the risk of ignition in potentially explosive atmospheres. In summary, PP-EL electrically conductive plastic valves offer a safe and dependable solution for ATEX environments in the chemical and process industries. When selecting these valves, it is essential to consider the specific application requirements as well as the applicable standards and regulations for operating in potentially explosive atmospheres. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|