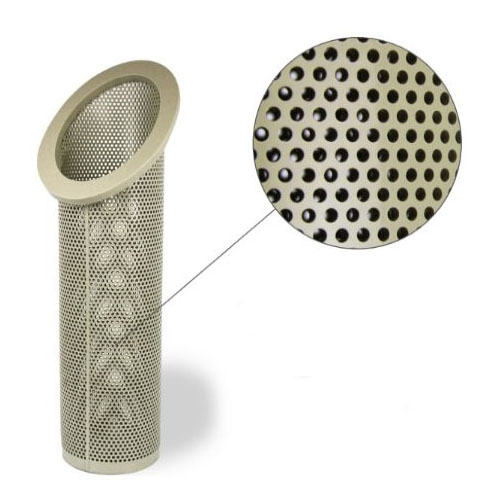

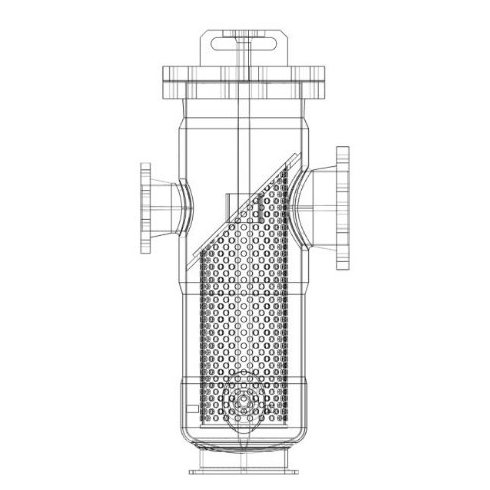

Strainer Inliner PP / FRP coated - angle seat strainer

delivery time: 3 weeks

|

| DN200 Design pressure: 6 bar with DIN fixed flange connection d150 (DN160) DN200 Design pressure: 10 bar with DIN fixed flange connection d150 (DN160) DN400 Design pressure: 4 bar with DIN fixed flange connection d315 (DN300) Design temperature max. 40°C |

|

|

||||||||||||||||||||||||||||||

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reliable dirt traps for smooth operations - Kwerk GmbH stands for quality in the chemical industry |

|

|

Efficient Strainers for Contaminant Elimination in Flowing Liquids |

|

Our strainers are specifically designed to eliminate contaminants in flowing liquids, preventing blockages and equipment failures such as pumps, valves, and spray nozzles. The selection of the appropriate perforations/mesh size of our PP strainers depends on the size of the dirt particles. Kwerk GmbH has developed these strainers for heavy-duty chemical applications. In addition to the PP/FRP version, we also supply ECTFE/FRP and PVDF/FRP strainers in three standard sizes: DN 200, DN 300, and DN 500. Stamped PP plates with perforations of 2.0 mm, 3.0 mm, 4.0 mm, and 5.0 mm are available as sieve baskets. Upon request, we can also manufacture custom-designed strainers to meet specific requirements. We are pleased to offer you a selection of products from the Chemiedur® series, ensuring long service life and high operational reliability for your system. If you have any questions, please feel free to call us at +49 2602 999 730. |

|

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|