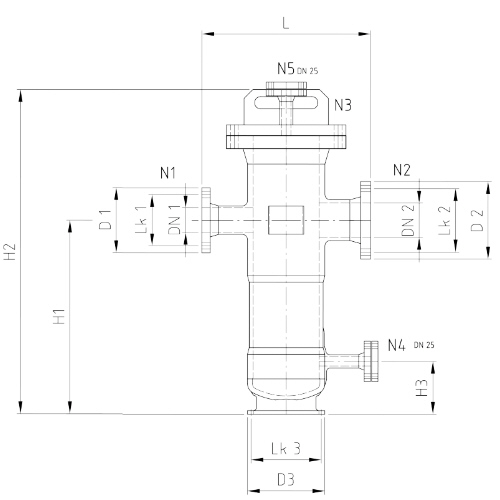

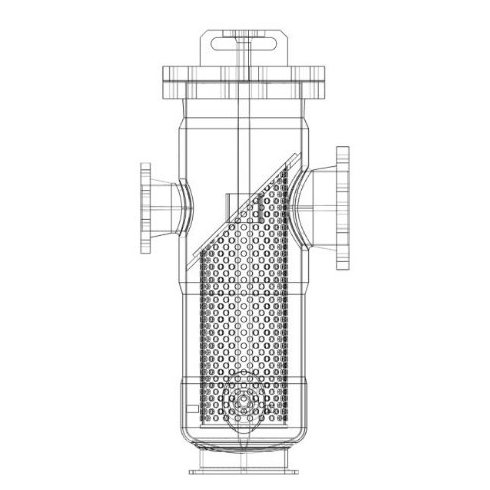

Strainer Inliner FRP / CBL coated - Design POT Strainer

delivery time: 3 weeks

|

||||||||||||||||||||||||||||

|

Sizes and Designs Pot Strainer Inliner FRP / CBL coated in size: DN200 Optionally with DIN fixed flange connection d75 (DN65), d90 (DN80) or d110 (DN100) DN300 Optionally with DIN fixed flange connection d140 (DN125), d160 (DN150) or d225 (DN200) DN500 Optionally with DIN fixed flange connection d280 (DN250) or d315 (DN300) Available Mesh sizes Ø 2,0 mm , Ø 3,0 mm Ø 4,0 mm oder Ø 5,0 mm more on request Accessories Accessories such as manometer, differential pressure measurement, drain or vent valve on request. Design data Pressure: max. 6 bar for sizes DN200 / DN300 max. 4 bar for sizes DN500 Temperature: max. 100°C |

|

|||||||||||||||||||||||||||

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reliable dirt traps for smooth operations - Kwerk GmbH stands for quality in the chemical industry |

|

|

Efficient Strainers for Contaminant Elimination in Flowing Liquids |

|

Our strainers are specifically designed to eliminate contaminants in flowing liquids, preventing blockages and equipment failures such as pumps, valves, and spray nozzles. The selection of the appropriate perforations/mesh size of our PP strainers depends on the size of the dirt particles. Kwerk GmbH has developed these strainers for heavy-duty chemical applications. In addition to the PP/FRP version, we also supply ECTFE/FRP and PVDF/FRP strainers in three standard sizes: DN 200, DN 300, and DN 500. Stamped PP plates with perforations of 2.0 mm, 3.0 mm, 4.0 mm, and 5.0 mm are available as sieve baskets. Upon request, we can also manufacture custom-designed strainers to meet specific requirements. We are pleased to offer you a selection of products from the Chemiedur® series, ensuring long service life and high operational reliability for your system. If you have any questions, please feel free to call us at +49 2602 999 730. |

|

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|