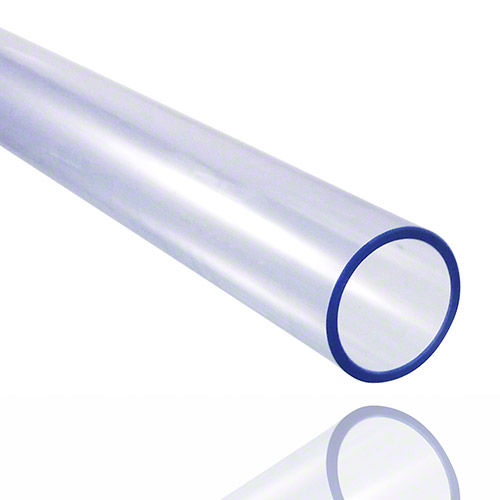

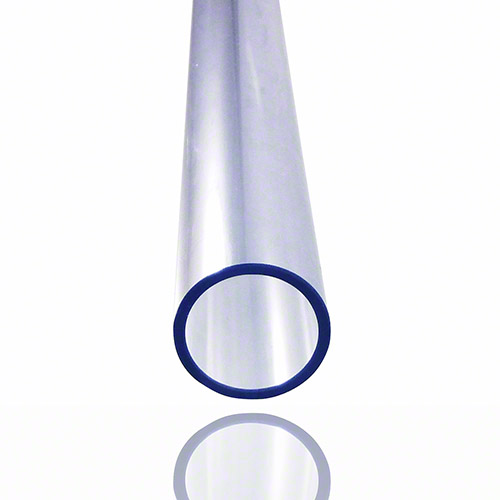

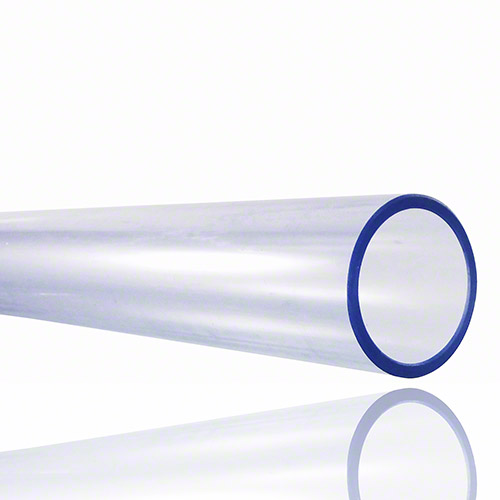

PVC U Transparent pipe according to DIN 8062 and ISO standard, PN 6

delivery time: 2-3 days

|

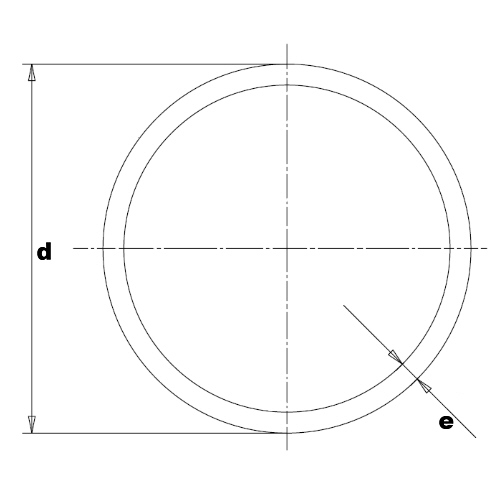

| - Pipe length: 5000mm, with plain ends - nominal pressure PN 6 - pipe cuts available on request - Material: PVC-U - Dimension: acc. to DIN 8062 - Colour: transparent - Transparency depends on outer diameter and wall thickness! Chemical and thermical stress can cause discolouration - Approval: food grade, with declaration of conformity acc. EU 10/2011 and EU 1593/2004, Approval on request |

|

|

||||||||||||||||||||||||||||||

Information:

Information:

|

||||||||||||||||||||||||||||||||||||||||||||||||||

Clear Insights for Your Pipe Systems - PVC-U Transparent Solutions that Impress |

|

Our PVC-U Transparent Pipe Systems impress with their outstanding characteristics and diverse applications. Made from PVC-U material according to DIN 8062, they offer high chemical resistance and corrosion resistance. Furthermore, they are proven to be physiologically harmless and comply with the requirements of the food industry according to EU 10/2011 and EU 1593/2004. With their transparent color, they enable visual control of flow, where transparency depends on the diameter and wall thickness. However, please note that chemical and thermal stresses may cause discoloration. Our PVC-U Transparent Pipe Systems are available in a length of 5000mm with plain endsand meet the highest quality standards. They are suitable for various applications in the chemical process industry, microelectronics, shipbuilding, and water treatment. Trust in proven quality and choose PVC-U Transparent Pipe Systems for safe and efficient solutions. Discover their versatile applications and benefit from their chemical resistance and corrosion resistance. Experience PVC-U Transparent Pipe Systems - the clear choice for your demanding applications! |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|