Y- Strainer made of PP, FPM O-Ring

delivery time: 5-6 days

|

|||||||||||||||||||||||||||||||||

|

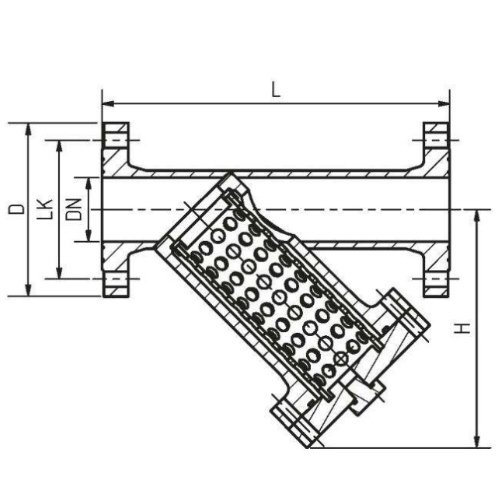

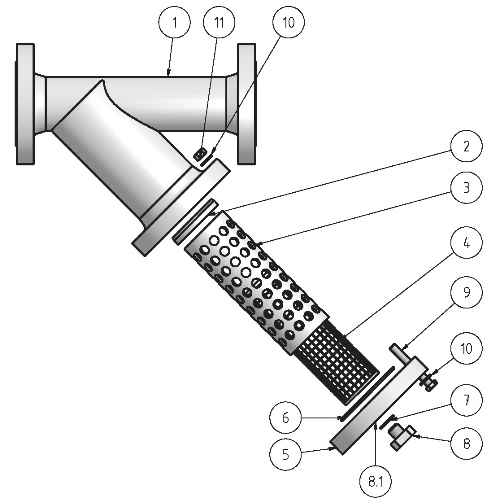

- body PP - bothside fixed flange DIN EN 1092-1, DIN 2501 - PN10 - O-Ring / Seal FPM - Standard mesh 2,0 mm alternative 0,5 mm + 0,25 mm + 1 mm other sizes by inquiry - Connection dimensions and installation lengths accord specification custom made - up to DN 500 by inquiry To protect valves, sensors and pumps from pollutants, we recommend the use of Strainers made of PVC, PP and PVDF. This ensures reliable operation and extended service life for your components. For higher requirements, we also offer a fiberglass-reinforced version. The broad product range includes different materials, end connectors, and standards, suiting a large variety of applications. Special solutions such as Pressure gauge port the outlet with ball valve or quick release of the strainer are possible on request. |

|

||||||||||||||||||||||||||||||||

Information:

Information:

Information:

Information:

Information:

Information:

Information:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Efficient Filtration for Optimal Performance |

|

INCLINED SEAT STRAINERS MADE OF PVC U, PP, AND PVDF In the field of plastic plant and apparatus construction, especially in the handling of acids and alkalis, inclined seat strainers are used in large nominal sizes to protect plant components such as valves, sensors, and pumps. These strainers are of great importance to plant operators as they ensure long service life and prevent potential disruptions. Inclined seat strainers are integrated into plastic pipelines. For highly demanding requirements, Kwerk GmbH also offers reinforced versions with fiberglass reinforcement. Kwerk GmbH manufactures a standard range of inclined seat strainers in its workshop and also provides customized solutions based on individual requirements and installation situations, such as pressure measurement connections, outlet with ball valve, or quick-release mechanism for the strainer. The strainers are manufactured in flange design according to fixed flange specifications in accordance with DIN EN 1092-1, DIN 2501/PN 10, or ANSI. The standard mesh size is 2.0 mm, alternatively 0.5 mm + 1 mm. Other mesh sizes are available upon request. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|