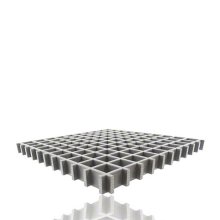

GFRP GRATINGShalogen free, silikone free, recyclable |

|

|

|

|

|

|

Glass fibre reinforced plastics, a plastic fibre composite, are economical, but nevertheless of high quality. The high ultimate strain and the elastic energy absorption is one of the main advantages of the glass fibre in combination with a matching plastic matrix. Glass fibre reinforced plastic shows an excellent corrosion behaviour, even in aggressive environments, which makes this material suitable for products e.g. in plant construction. The resin matrix we use has good electrical insulation properties, so it is the ideal choice for applications in the chemical technology and electrical engineering. We produce GFRP parts in various designs: Notice: Cutting edges of GFRP gratings are always sealed. Standard version: - GFRP grid - Max. temperature: 60°C - Resin: orthophtalic acid resin - Chemical resistance must be guaranteed, HCl, H2SO4, NaOH, ISO version: - GFRP grid - Max. temperature: 70°C - Resin: isophtalic acid resin - Chemical resistance must be guaranteed, HCl, H2SO4, NaOH, ISO-NPG version: - GFRP grid - Max. temperaturr: 75°C - Resin: isophtalic acid - neopenthyl glucol - Chemical resistance must be guaranteed, HCl, H2SO4, NaOH, VE version: - GFRP grid - Max. temperature: 105°C - Resin: VE = vinylester resin - Chemical resistance must be guaranteed, HCl, H2SO4, NaOH, B2 version: - GFRP grid - Max. temperature 70°C (fire assay up to 150°C ) - Resin: isophtalic acid resin - Chemical resistance is affected B1 version: - GFRP grid - Max. temperature 90°C (fire assay up to 650°C ) - Resin: UP fire protection resin - Chemical resistance is affected EL version (electronic load resistor of 106 - 108 Ohm) - GFRP grid - Max. temperature 70°C - Resin: isophtalic acid resin - Chemical resistance is affected GFRP grids are not resistant to hydrofluoric acid. Guarantees can only be given against submission of a specification. Below some examples for the application of GFRP gratings: - Paper industry - Automobile industry - Steel industry - Food industry - Plating industry - Pickling plants - Paper and pulp industry - Waterworks and power stations - Sewage treatment plants - Shipbuilding - Manhole and channel covers - Landing stages - Machine and plant engineering - Petrochemistry - Elektrolysis We will produce customized parts, meeting your personal requirements. Should you have any questions or specific requests, please contact us by telephone or use our contact form. |

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|