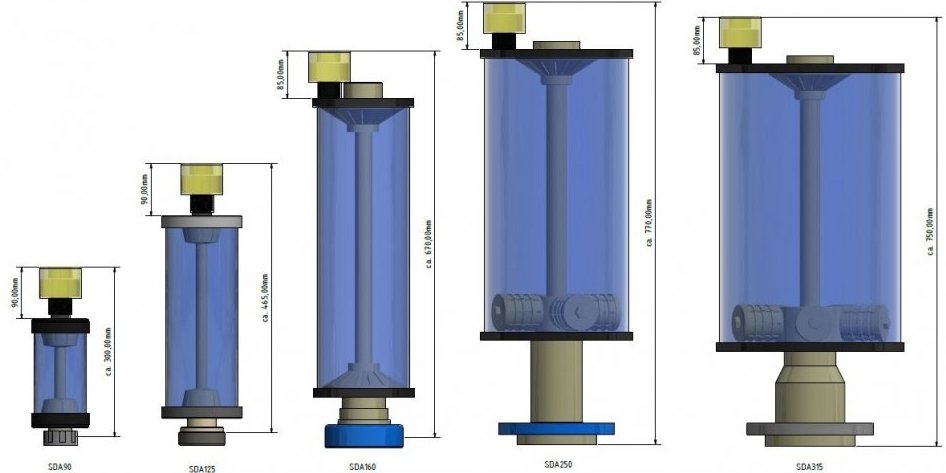

ACID VAPOR SEPARATORS FOR CHEMICAL CONTAINERSTYPES SDA 90 - SDA 315 |

|

In many industries the manufacture of products without additives is no longer conceivable. As a result various products and chemicals are used and get into production processes. Large amounts of chemicals are delivered, stored and processed. The resulting gases accumulate in tanks, pipes and vats or are released during processing. Frequently those gases are toxic, sometimes however only odorous. Conventional systems, such as activated carbon, do not provide sufficient safety for instance by means of a high air humidity level. Systems with synthetical chemical sorption media are characterised by high capacity, guaranteed efficiency and proven reliability. Acid vapor separators are used for absorption of hazardous chemical vapors, arising during filling, transfilling and emptying of closed and pressureless storage tanks. Our acid vapor separators and the dry granulate are suitable for all common media such as chemicals, acids, alkalis, oils and solvents. In many industrial sectors acid vapor separators are a cost-effective alternativeto cost-intensive gas scrubbing plants or exhaust air systems. Beyond that, acid vapor separators offer simple handling and the possibility of adjustment to various tanks. With a filling level matching the process, you keep the costs under control without violating the regulations with regard to industrial safety and health protection. For all industrial plants, safety measures to protect employees have first priority. Please ask our technicians for advice. Dimensions not specified as well as other dimensions and materials can be delivered on request. All items you will also find in our webshop. |

|

|

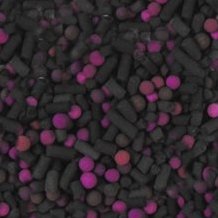

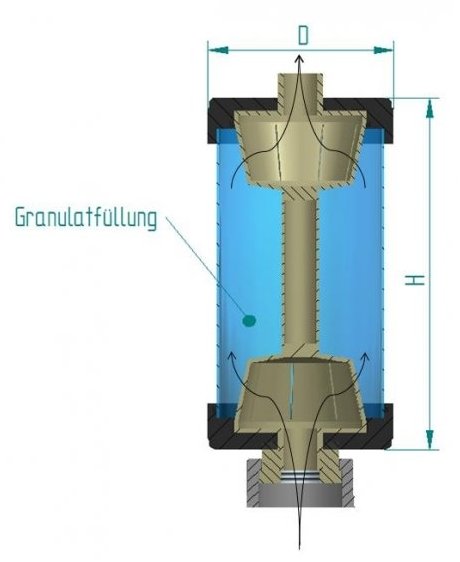

Acid vapor separatorChemical sorption media are dry granules filtering and neutralizing harmful gases by means of oxidation. - high filter efficiency, more than 99 % - excellent filter capacity - cost-effective small applications - simple installation - low servicing and maintenance Features: - UL class 2, classified as difficult to ignite - non-flammable - non-toxic The filter effect is based on absorption, adsorption and the chemical reaction. Gases come into contact with the filter media and are neutralized by means of oxidation, leaving behind mineral residues. Desorption is not possible anymore. Periodical chemical analyses allow an exact forecast for granules change and complete service for secure availability. Information about accident prevention: During installation and disposal dust masks, safety glasses and rubber gloves should be worn. Disposal must be carried out in accordance with local regulations. |

Technical data and overview of different variants - acid vapor separator - |

|

|

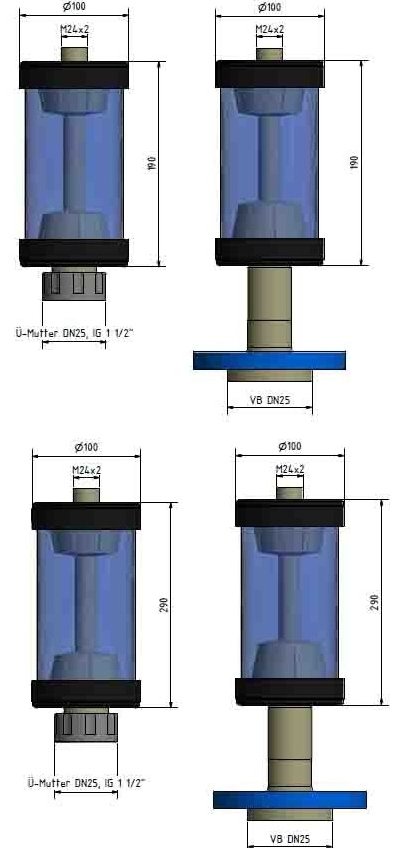

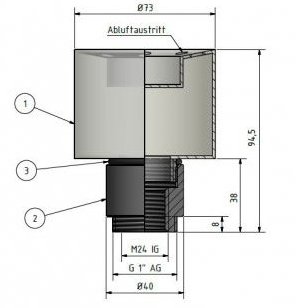

Acid Vapor Separator SDA 90 - Technical Specifications -- Material: Cover/Base - PE - Pipe: PVC (transparent) - Inner Rod: PP - Union Nut: PP - Flange: PVC - Diameter: approximately 100 mm - Installed Height: approximately 220 mm - Connection: Union Nut DN25 (d=32) with IG R1 1/2" Inch Thread - Optional: Pre-welded Flange with Loose Flange DN25 (d=32) - Capacity: approximately 0.6 liters - Airflow Rate: 25 liters/min Acid Vapor Separator SDA 90 - Technical Specifications -

|

Delivery program acid vapor separators of type SDA 90 - with screwed connection -All items you will also find in our webshop. |

|

|

|

|

Delivery program acid vapor separators of type SDA 90 - with flange connection -All items you will also find in our webshop. |

|

|

|

|

|

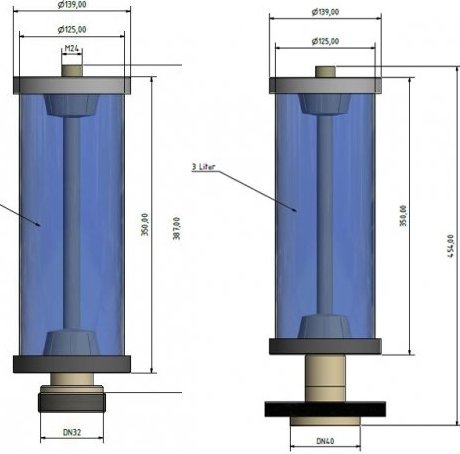

Acid vapor separator SDA 125 - Technical data -- Material of bottom and cap: PE - Tube: PVC (transparent) - Internal rod: PP - Union nut: PP - Flange: PVC - Diameter: approx. see table - Installation height: see table - Connection: union nut DN32 (d=40) with R2 inch internal thread - Optional: welding collar with loose flange DN40 (d=50) - Contents: approx. 3,0 liter - Exhaust air throughput: 25 liters/min The acid vapor separator SDA 125 is particularly suitable for small packaging sizes, such as dosing tanks, IBC containers and other industrial containers. Whenever there are no exhaust air systems in industrial plants, acid vapor separators offer a good technical alternative for occupational safety. Filling the acid vapor separator with granulate and discharging can be done easily by means of screw caps. In our series IBC caps you will find a variety of options for filling and removal of liquids from IBC containers. which is in combination with a acid liquid separator the ideal supplement in industriel plants. Suitable for indoor installation. Outside use is possible on request. Dimensions not specified as well as other dimensions and materials can be delivered on request. All items you will also find in our webshop. |

|

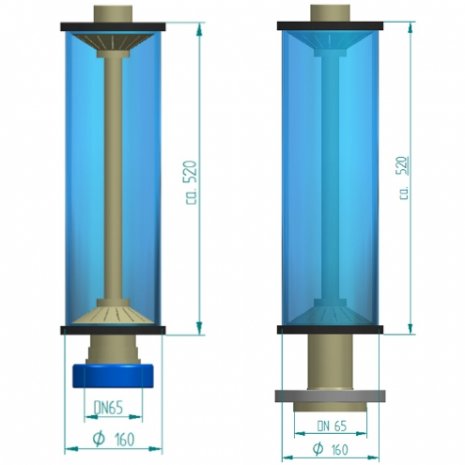

Acid vapor separator SDA 160 - Technical data -- Material of bottom and cap: PE - Tube: PVC (transparent) - Internal rod: PP - Union nut: PP - Flange: PVC - Diameter: approx. 170 mm - Installation height: approx. 590 mm - Connection: union nut DN65 (d=75 mm), alternative +GF TR 180x5 trapezoid thread - Optional: welding collar with loose flange DN65 (d=75) - Contents: approx. 7 liters - Exhaust air throughput: 160 liters/min - Suitable for indoor installation. Outside use is possible on request. Dimensions not specified as well as other dimensions and materials can be delivered on request. All items you will also find in our webshop. |

Delivery program acid vapor separator of type SDA 160 - with screwed connection -All items you will also find in our webshop. |

|

|

|

|

Delivery program acid vapor separators of type SDA 160 - with flange connection -All items you will also find in our webshop. |

|

|

|

|

|

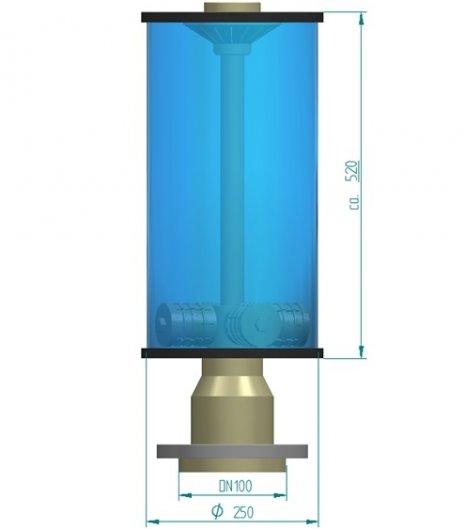

Acid vapor separator SDA 250 - Technical data -- Material of bottom and cap: PE - Tube: PVC (transparent) - Internal rod: PP - Union nut: PP - Flange: PP/steel - Diameter: approx. 260 mm - Installation height: approx. 615 mm - Connection: loose flange d 90 mm or d 110 mm - Contents: 15 liters - Suitable for indoor installation. Outside use is possible on request. Dimensions not specified as well as other dimensions and materials can be delivered on request. All items you will also find in our webshop. |

Delivery program acid vapor separators of type SDA 250 - with flange connection DN 80 or DN 100 -All items you will also find in our webshop |

|

|

|

|

|

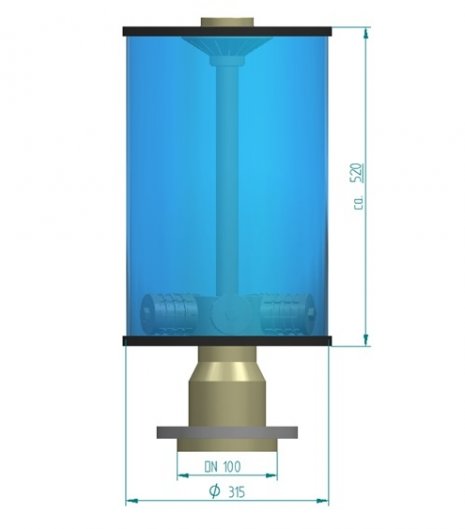

Acid vapor separator SDA 315 - Technical data -- Material of bottom and cap: PE - Tube: PVC (transparent) - Internal rod: PP - Union nut: PP - Flange: PP/steel - Diameter: approx. 325 mm - Installation height: approx. 800 mm - Connection: loose flange d 110 mm - Contents: 25 liters - Suitable for indoor installation. Outside use is possible on request. Dimensions not specified as well as other dimensions and materials can be delivered on request. All items you will also find in our webshop. |

Delivery program acid vapor separator of type SDA 315 - with flange connection -All items you will also find in our webshop. |

|

|

|

|

|

INDICATOR CARTRIDGE FOR ACID AND LYEOn all SDA 90 - SDA 350 acid vapor separators, we adapt so - called INDICATOR CARTRIDGES for the indication acid and LAUGE as optical indication for the detection of the saturation of the used granules for acid vapor separators. For the SDA 90, the INDICATOR CARTRIDGE is screwed on with an internal thread, and for types SDA 160, SDA 250 and SDA 315, an internal thread for the INDICATOR is optionally inserted on the cover. i.e. If necessary, you can also retroactively retrofit your SDAs with the INDICATOR. For installation, only the security label has to be removed and the cartridge screwed on. When using granulate filling, the INDICATOR turns from BLUE to YELLOW when using acidic vapors, and when using lukewarm vapors, the color changes from BLUE to WHITE. Once you detect a color change, both the granules for the SDA and the INDICATOR are consumed. This technical solution gives you security when dealing with acid and alkalis and you will recognize the change interval immediately after outgassing of the acid and lye on the color change. |

Total structure acid vapor separator with Indicator Cartridge - Overview - |

INDICATOR - CARTRIDGE FOR ACID AND LAUGEAcid: Color change BLUE - YELLOW Lye: Color change BLUE - WHITE |

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

CHEMICAL SORPTION MEDIA AS DRY GRANULATESFor acid vapor separators of types SDA 90, SDA 90-1L, SDA 125, SDA 160, SDA 250 und SDA 315 |

|

||||||||||||||||||||||||||||||||||

|

MEDIA LIST ACID VAPOR SEPARATORThe substances listed in the following table represent a selection of the customary chemicals for storage and dosing tanks. Dry granulates for special media apart from the table we can deliver after careful verification on request. Please send us your inquiry. All granulates you will also find in our webshop. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Optimize your shopping experience with our detailed delivery information |

Partnership at the highest level. |

|

|

|

|

|

|

|